Bearing assembly for wind driven generator

A technology for wind turbines and bearing components, which is applied in the direction of wind turbines, wind power generation, bearing components, etc., can solve the problems of inconvenient installation of shaft current insulation parts, difficulty in replacement, and high installation costs, and achieve convenient molding and effective layout. Avoid electric corrosion of bearings and facilitate processing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

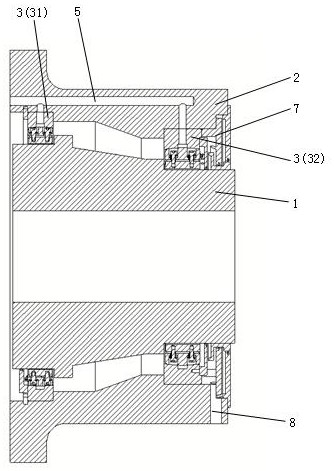

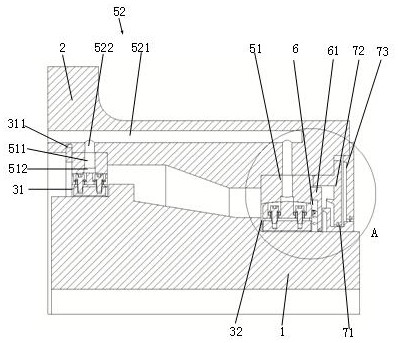

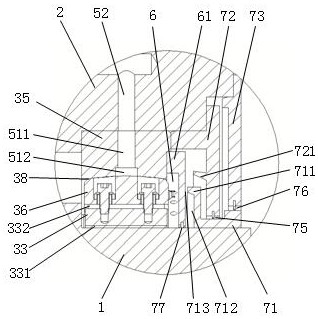

[0062] Such as Figure 1 to Figure 18 As shown, the bearing assembly for a wind power generator in this embodiment includes a rotating shaft 1 , a bearing seat 2 , a front bearing component 31 and a rear bearing component 32 . Among them, the rotating shaft 1 is connected with the rotor of the generator, and is used to transmit the torque and load of the rotor of the wind turbine, and is a rotating part; the bearing seat 2 is connected with the base of the generator, and bears the weight and other loads of the rotor of the wind turbine, and is a stationary component. Components; the front bearing part 31 and the rear bearing part 32 are arranged between the rotating shaft 1 and the bearing seat 2 to support the normal operation of the rotating shaft 1 and the parts between the rotating shaft 1 during the rotation. In this embodiment, both the front bearing component 31 and the rear bearing component 32 are sliding bearings 3 , and the sliding bearing 3 includes a bearing body ...

Embodiment 2

[0100] Figure 20 to Figure 29 It shows another embodiment of a bearing assembly for a wind power generator of the present invention, this embodiment is basically the same as the previous embodiment, the difference is that the sliding bearing 3 of this embodiment cancels the setting of the bearing housing 35, and A swing adjustment structure is provided between the radial shoe 33 and the bearing body 36 . That is, the swing form of setting the self-aligning block 39 between the radial shoe 33 and the bearing body 36 is used instead of the swing form of setting the swing adjustment part 38 between the bearing shell 35 and the bearing body 36, which solves the problem of load deflection. At the same time, the bearing arrangement space is minimized.

[0101] Specifically, the sliding bearing 3 further includes an aligning block 39 and a second limiting member. The self-aligning block 39 is installed on the radial tile 33, and the self-aligning block 39 is located between the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com