A low noise forward curved centrifugal fan impeller

A centrifugal fan and impeller technology, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as noise, achieve the effect of reducing severe impact and improving wake-jet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with specific embodiments.

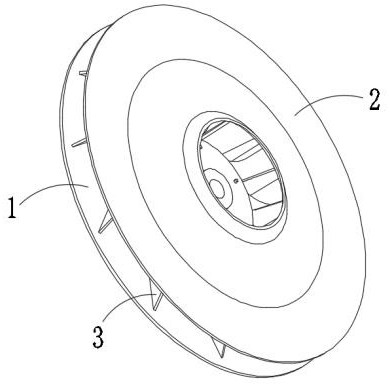

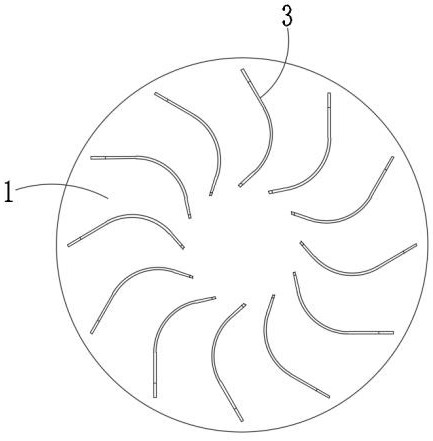

[0031] The present invention provides a low noise forward bending centrifugal fan impeller, such as Figures 1 through 7 Shown, comprising a base plate 1, a top plate 2 and a circumferential array connected to a plurality of blades between the bottom plate 1 and the top plate 2 3. Preferably, the blade 3 is a sheet metal blade with a thickness of 1.5-5mm, there are 12 blades 3 in a circumferential array between the base plate 1 and the top plate 2.

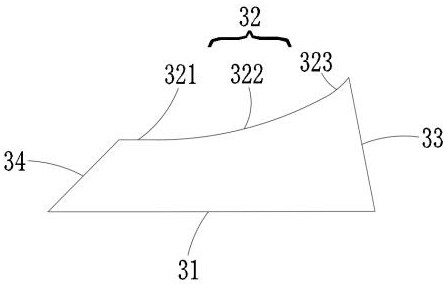

[0032] as Figure 3 As shown, the profile of the planar unfolding structure of the blade 3 is as follows: comprising the bottom edge 31 connected to the bottom plate 1 and the top edge 32 connected to the top plate 2, the inlet end of the bottom edge 31 is connected to the inlet edge 33 extending upwards, the outlet end of the bottom edge 31 is connected to the outlet bevel 34 that extends upwards in the direction of the impeller, the o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap