Double-screw bilateral asymmetric rotor profile composed of nine tooth curves

A rotor profile, asymmetric technology, applied in the field of compressor components, compressors and vacuum pump rotors, can solve the problems of increasing manufacturing cost, layout space, large leakage and noise, reducing compressor efficiency, etc., to improve processing performance. , the effect of reducing leakage and improving compressor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

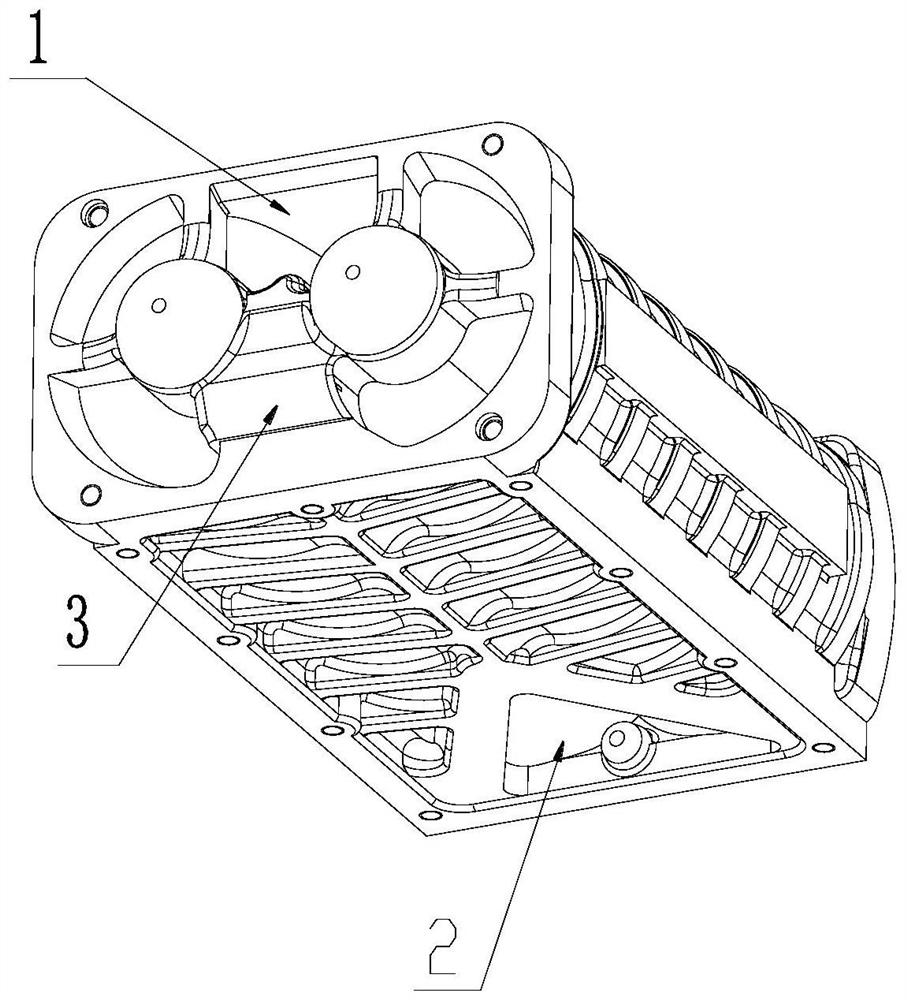

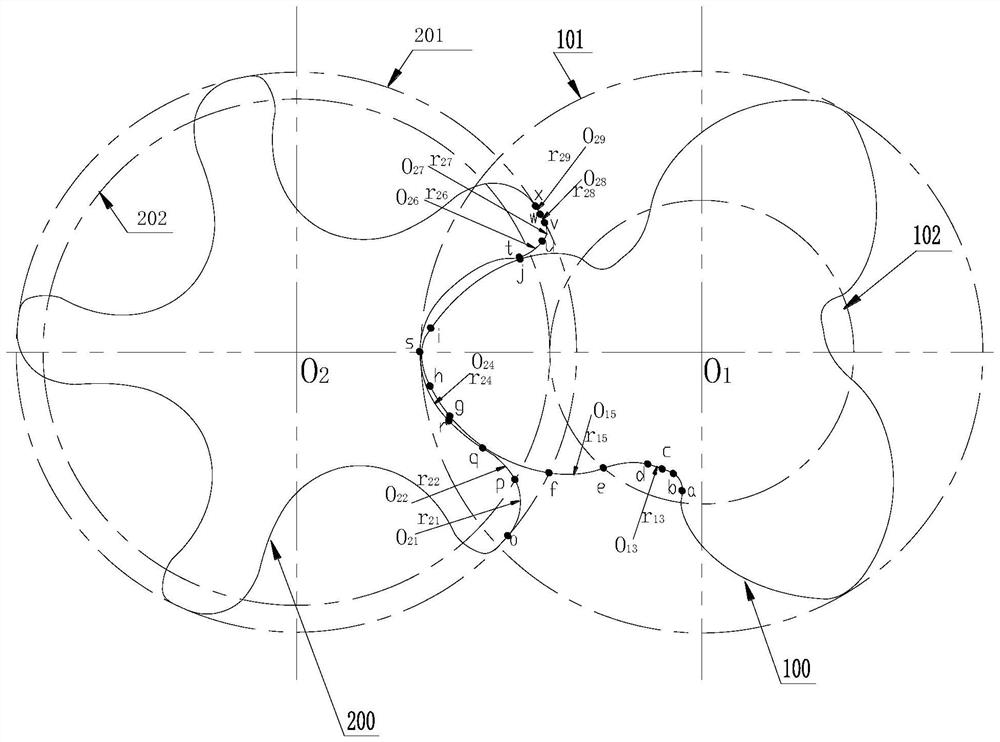

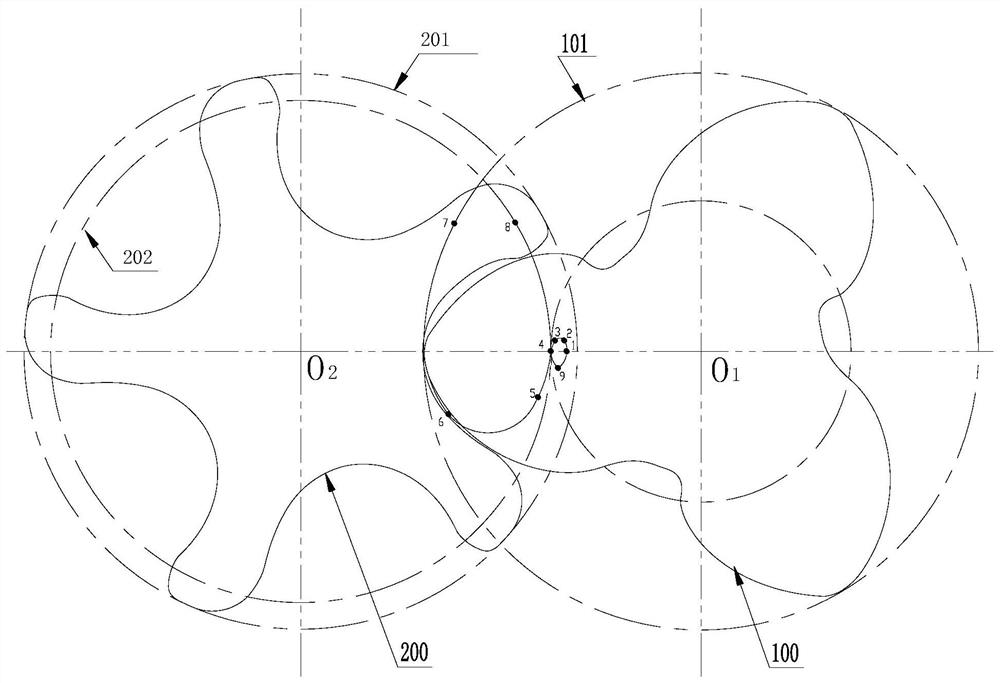

[0075] combine figure 1 , figure 2 As shown, according to the present invention, a twin-screw bilateral asymmetric rotor profile composed of nine-segment tooth curves, and the working process of the screw compressor can be divided into three processes: suction, compression and exhaust. As the rotor of the screw compressor rotates, each pair of meshing teeth completes the same working cycle successively, and the working cycle process is combined figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com