Outer cantilever frame for outer curtain wall construction and installation and construction method of outer cantilever frame

A construction method and technology for external curtain wall, applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of inconvenient installation and disassembly, poor safety guarantee, complex structure, etc., and achieve easy assembly, simple structure, Good stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

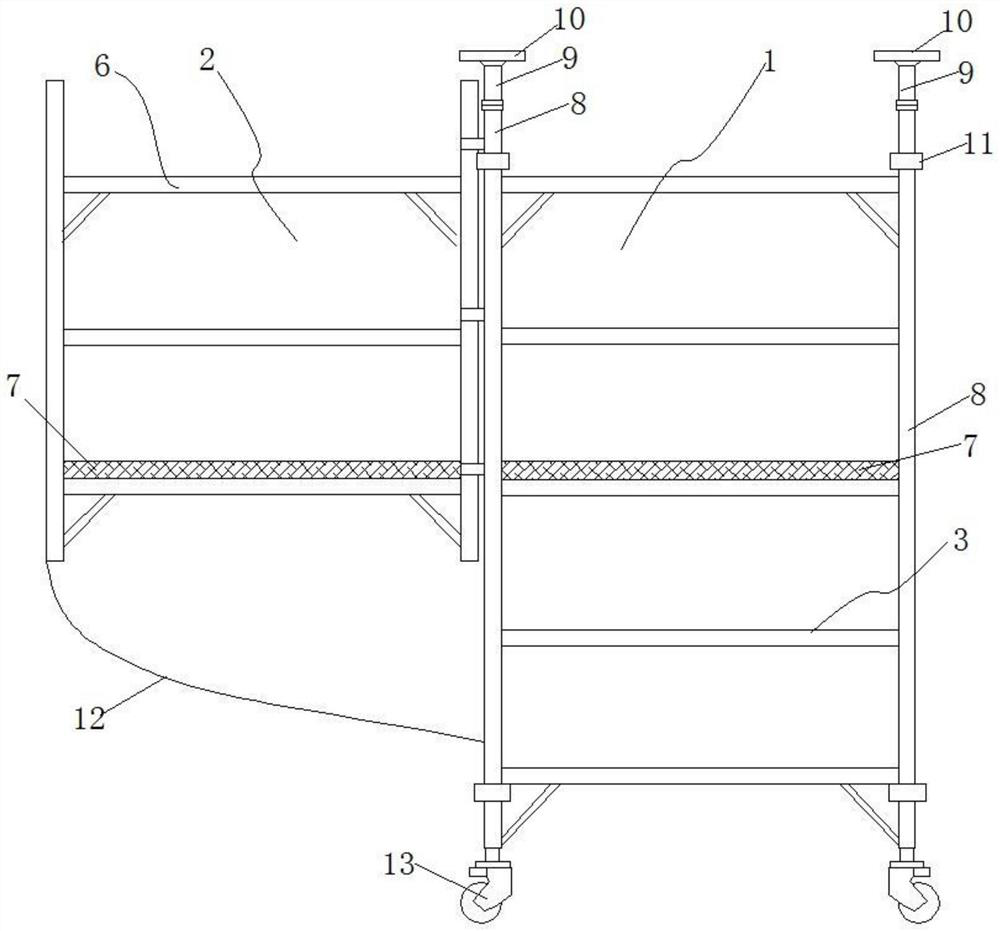

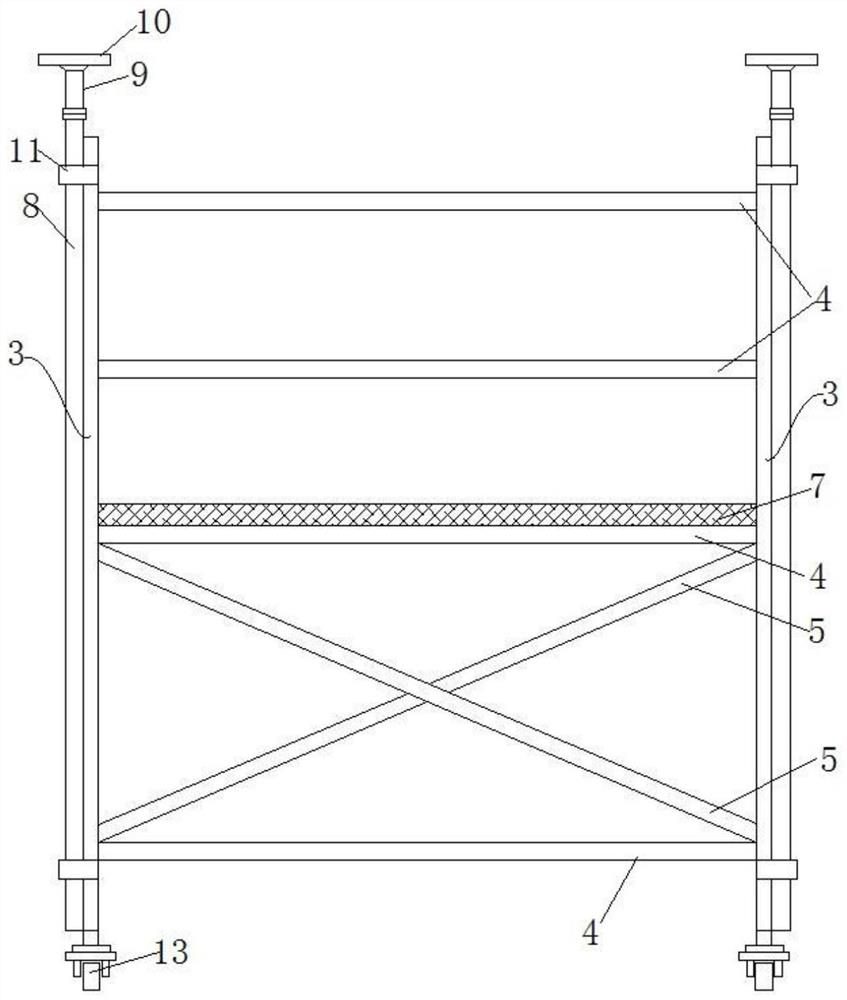

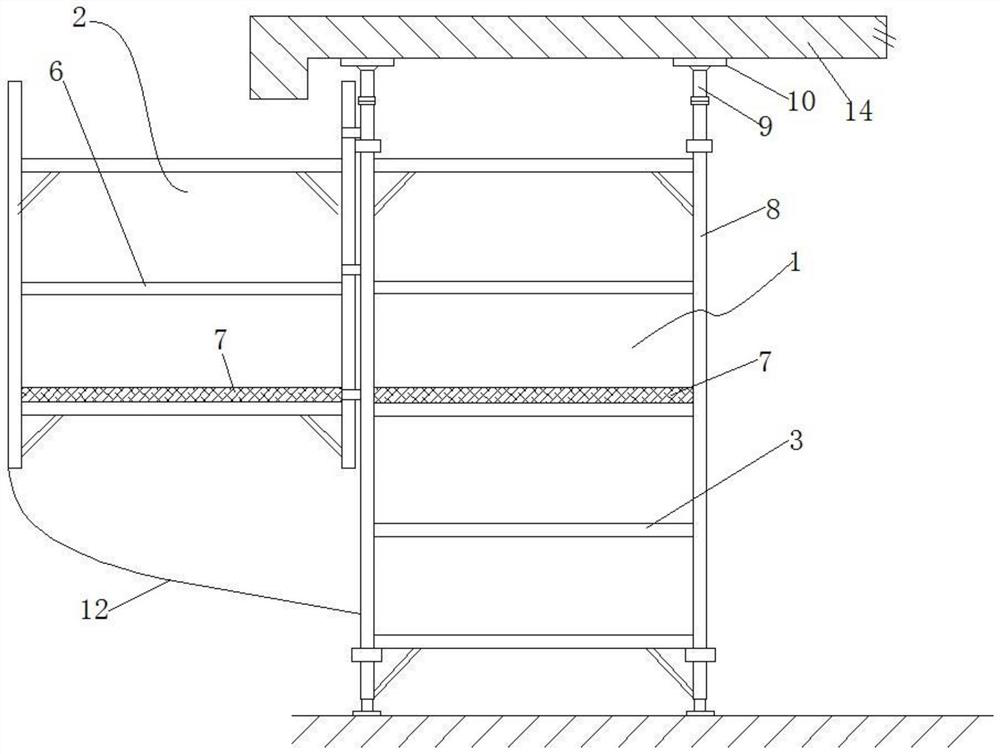

[0051] Such as Figure 1 ~ Figure 3 As shown, a kind of overhanging frame used for exterior curtain wall construction includes a pair of double-width five-stage frames 3 arranged indoors, and several cross braces 4 and diagonal braces are passed between a pair of said double-width five-stage frames 3 5 Build and form an indoor scaffolding 1, and the upper side of the double-width five-stage frame 3 is respectively connected with a double-width three-stage frame 6, and a pair of double-width three-stage frames 6 are connected by several cross braces 4 to form an overhanging part 2. The indoor scaffolding 1 and the overhanging part 2 are connected and installed with a platform board 7 at the same height through brackets, and the indoor scaffolding 1 and the overhanging part 2 are connected at the platform board 7 Channel; each vertical rod of a pair of double-width five-stage racks 3 is connected with a vertical rod 8, and the upper ends of the vertical rods 8 abut against the r...

Embodiment 2

[0065] This embodiment provides the usage structure and installation method of the outrigger in the first embodiment.

[0066] The widths of the double-wide five-level frame 3 and the double-wide three-level frame 6 are 1.3m, and the distance between a pair of the double-wide five-level frame 3 and the distance between a pair of the double-wide three-level frame 6 The distance between them is 1.9m, and the total height of the double-width five-stage frame 3 and the vertical pole 8 is not less than 2.8m.

[0067] The installation method of the outrigger is as follows:

[0068] (1) Get a pair of described double-wide five-level frame 3, a pair of cross brace 4 and four moving wheels 13, after described moving wheel 13 is installed on the bottom of described double-wide five-level frame 3 respectively, then put A pair of cross braces 4 are respectively connected between a pair of double-width five-stage frames 3 to obtain a preliminary forming structure of the scaffold;

[0069...

Embodiment 3

[0075] This embodiment provides a safety calculation method for the outriggers in Embodiments 1 and 2.

[0076] Assume that the load-bearing capacity of the indoor floor is required to be greater than 300kg / m 2 , the waviness formed with the ground when the indoor scaffold moves is less than 50, the scaffold can carry 4-6 people, and the average load of each platform board is 272kg / m 2 .

[0077] The overhanging frame also includes the steps of safety calculation and analysis during the installation and fabrication process:

[0078] (1) Calculation and analysis of overall security: Let the total allowable workload be F 总=900kg (the load is evenly distributed, not too concentrated), the total weight of the outrigger is m=145kg, from the overall stress analysis of the outrigger, it can be seen that the load of each support point at the lowest part of the scaffold in the room is the largest (4 supports point), the average load f of each support point is:

[0079]

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com