Machine and method for producing fibrous web

A fibrous material and machine technology, applied in the field of manufacturing fibrous material web, to achieve high specific volume value, reduce line load and optimize the effect of web quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

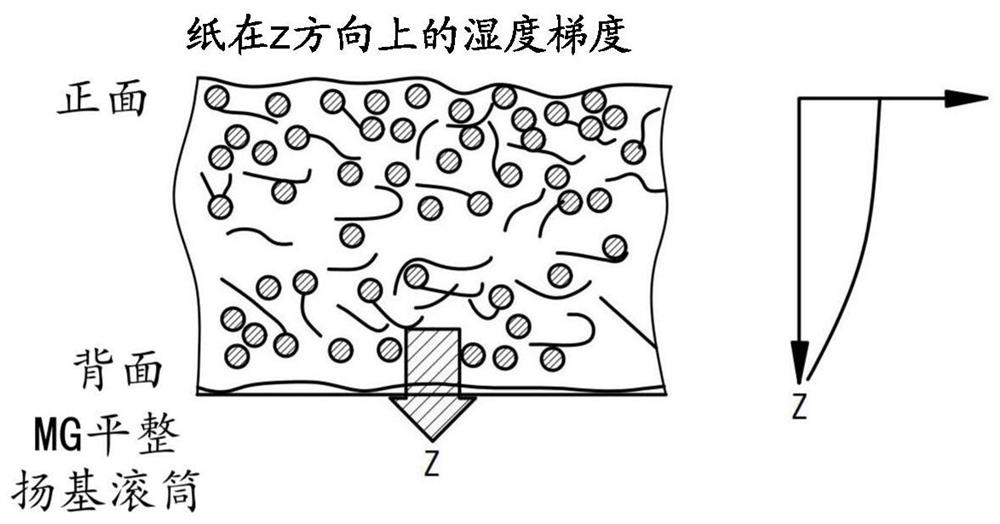

[0046] figure 1 The formation of the moisture gradient in the z-direction of the fibrous web obtained by one-sided predrying of the fibrous web on the bottom side of the fibrous web is schematically shown.

[0047] Then, due to the unilateral predrying on the bottom side of the web, a moisture gradient develops towards the top side of the fibrous web, which means that the bottom side of the fibrous web in contact with the MG smoothing Yankee cylinder has a lower moisture content than its top side moisture content. However, this is diametrically opposed to the pursuit of optimum quality properties on the bottom side of the fibrous web in contact with the MG smoothing Yankee cylinder.

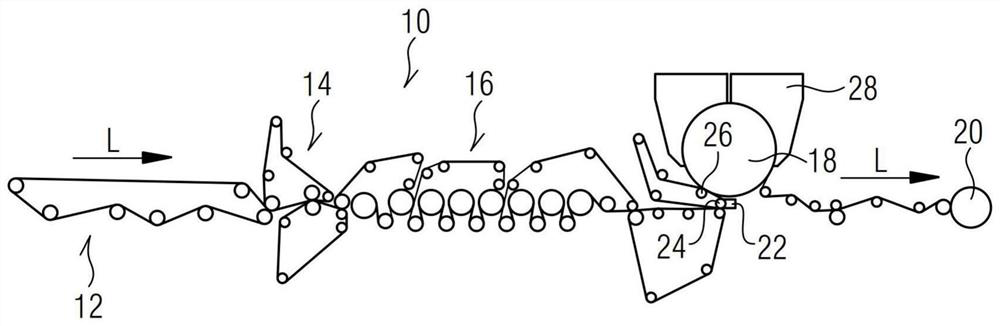

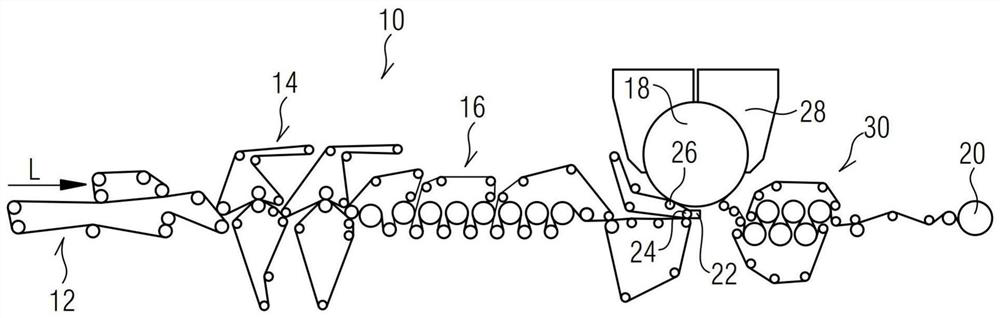

[0048] figure 2 and 3 A purely exemplary embodiment of a machine according to the invention for producing a fibrous web, in particular a paper or cardboard web, is shown schematically with the highest possible running performance of the machine and a relatively low grammage of the fibrous web...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com