Breathing unfreezing charging gun, charging pile with charging gun and method

A technology of charging gun and breathing port, which is applied in the field of breathing thawing charging gun, which can solve the problems of unable to pull out normally, freezing of charging gun, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

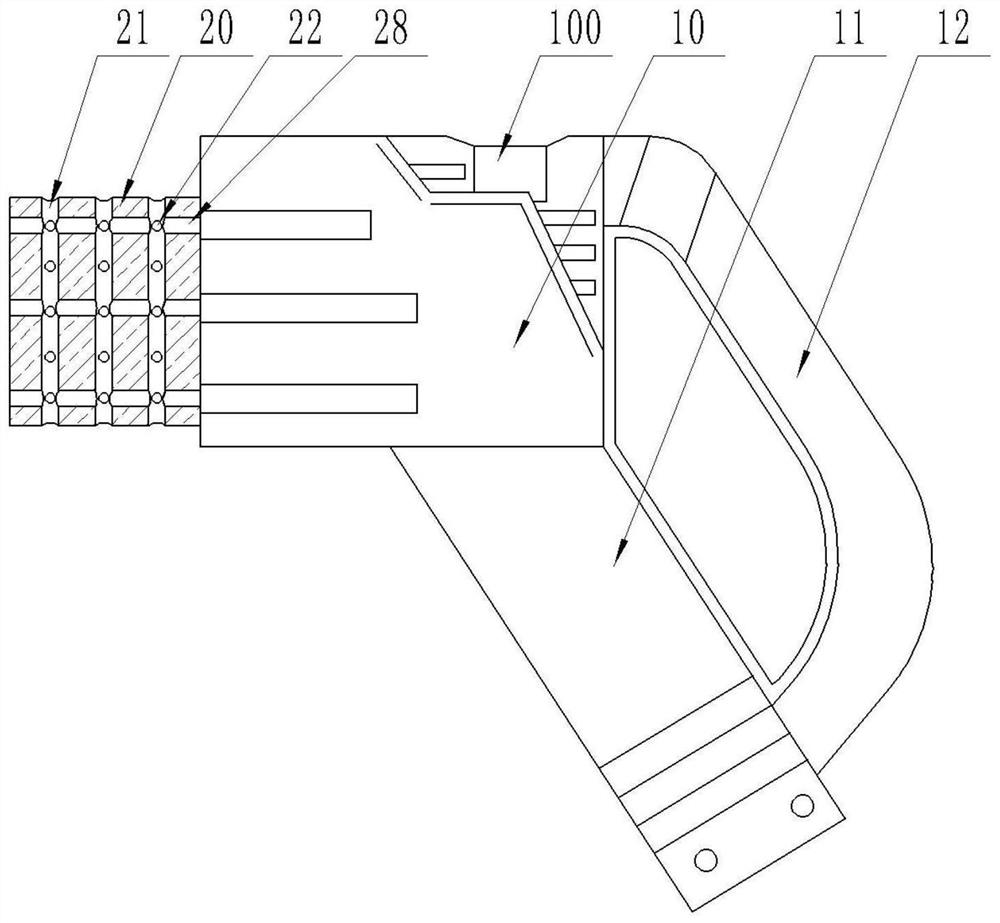

[0060] A breathing and unfreezing charging gun 100, wherein, such as Figure 1-3 As shown, it includes: a charging body 10 , a charging plug 20 , and a breathing assembly 30 .

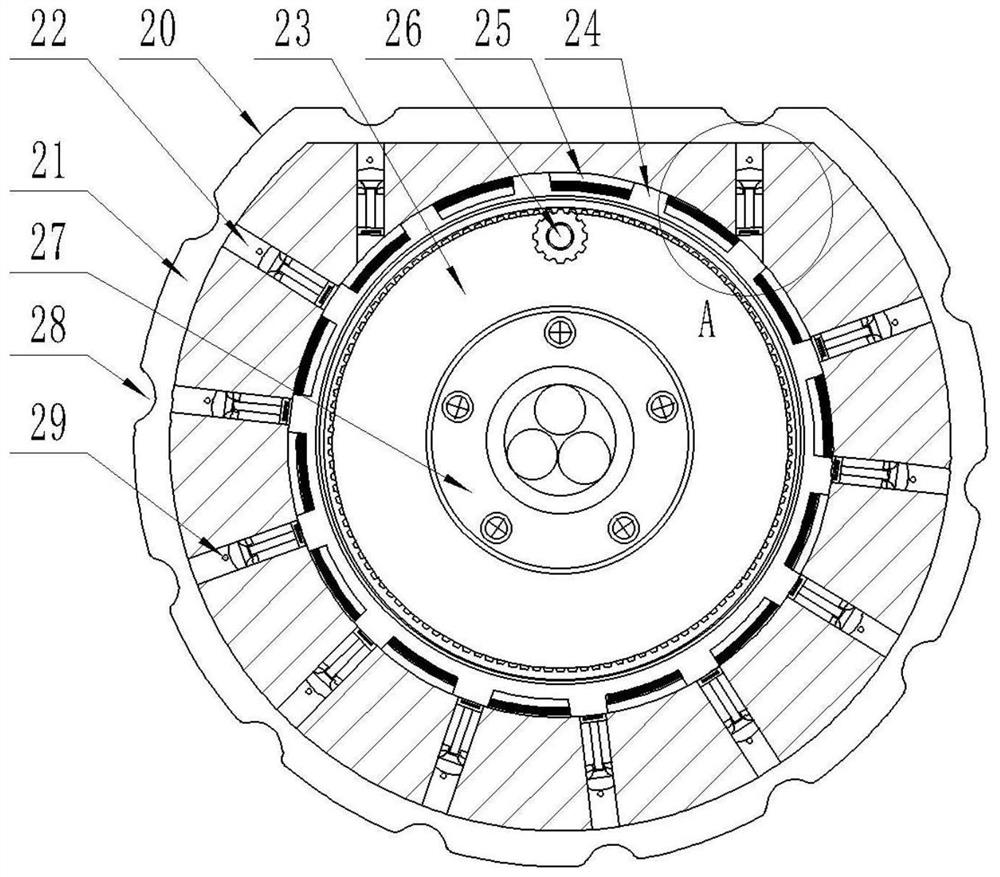

[0061] like figure 2 , 3 As shown, the charging plug 20 is installed at the front end of the charging body 10 , and the charging plug 20 has: an annular groove 21 , a breathing port 22 , an active cavity 23 , an active ring 24 , and a power gear 26 .

[0062] The annular grooves 21 are distributed on the outer surface of the charging plug 20 . The breathing port 22 is arranged in the annular groove 21, and the breathing port 22 communicates with the outside world.

[0063] Breathing ports 22 are distributed around the movable chamber 23 . The movable ring 24 is rotatably installed in the movable chamber 23, and the first magnet block 25 is embedded on the annular outer surface of the movable ring 24, and the first magnet block 25 is uniformly and radially distributed on the movable ring 24, and a ...

Embodiment 2

[0080] A breath thawing charging gun 100 has the same characteristic structure as that of Embodiment 1, wherein, as Figure 7 , 8 As shown, the breathing head 31 is a sheath structure made of elastic material, the side of the sheath structure is supported by the skeleton, and the upper end of the sheath structure is fixed by the support head 34, the support head 34 is connected with the cylinder, and the skeleton is inserted into the The sliding sleeve 35 of the cylinder is connected, and the sliding sleeve 35 is also connected with the bottom of the sheath.

[0081] A pressure spring 36 is connected between the support head 34 and the sliding sleeve 35 .

[0082] like Figure 9 As shown, when the breathing head 31 alternately slides back and forth along the breathing port 22, impurities and sewage may fall into the breathing port 22, and after a long time, the combination of impurities and sewage will usually invade the breathing port 22 and the relative of the breathing he...

Embodiment 3

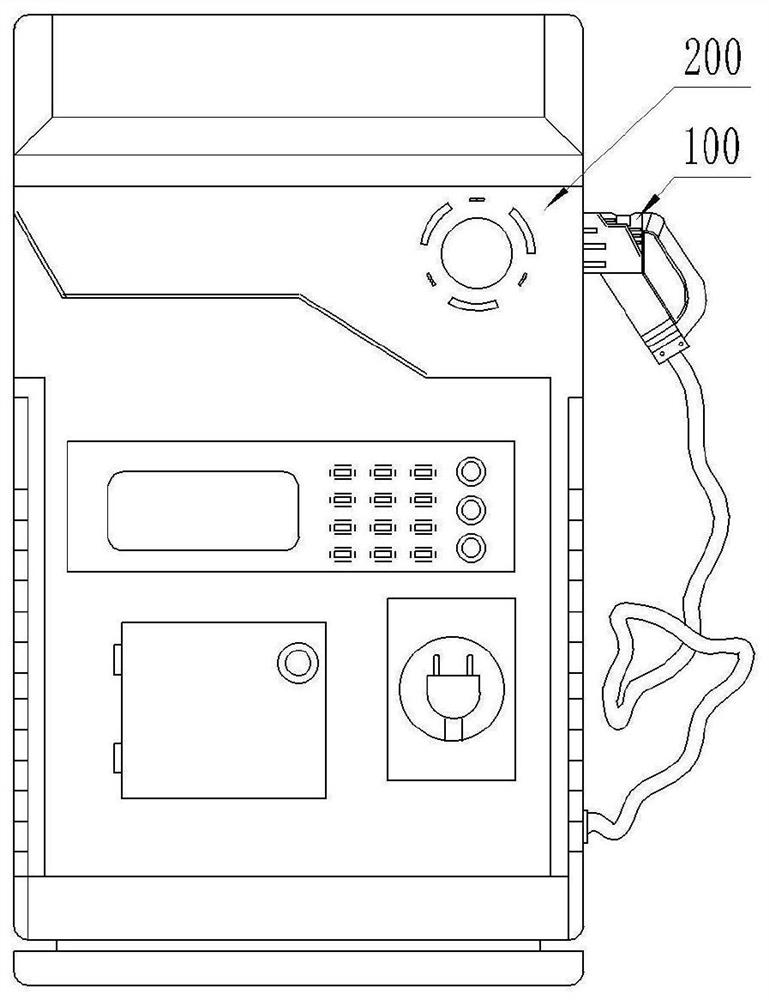

[0084] A charging pile 200, such as figure 1 As shown, wherein, there is the breath-thawing charging gun 100 in the first or second embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com