Automatic assembling device for sponge on inner side of cylindrical air conditioner panel

A technology of automatic assembly device and air-conditioning panel, applied in metal processing, connecting components, metal processing equipment, etc., can solve the problems of the sponge sheet being sticked skewed, sticking hollow, affecting the overall appearance, etc., to ensure the overall appearance, prevent The effect of condensation and noise blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

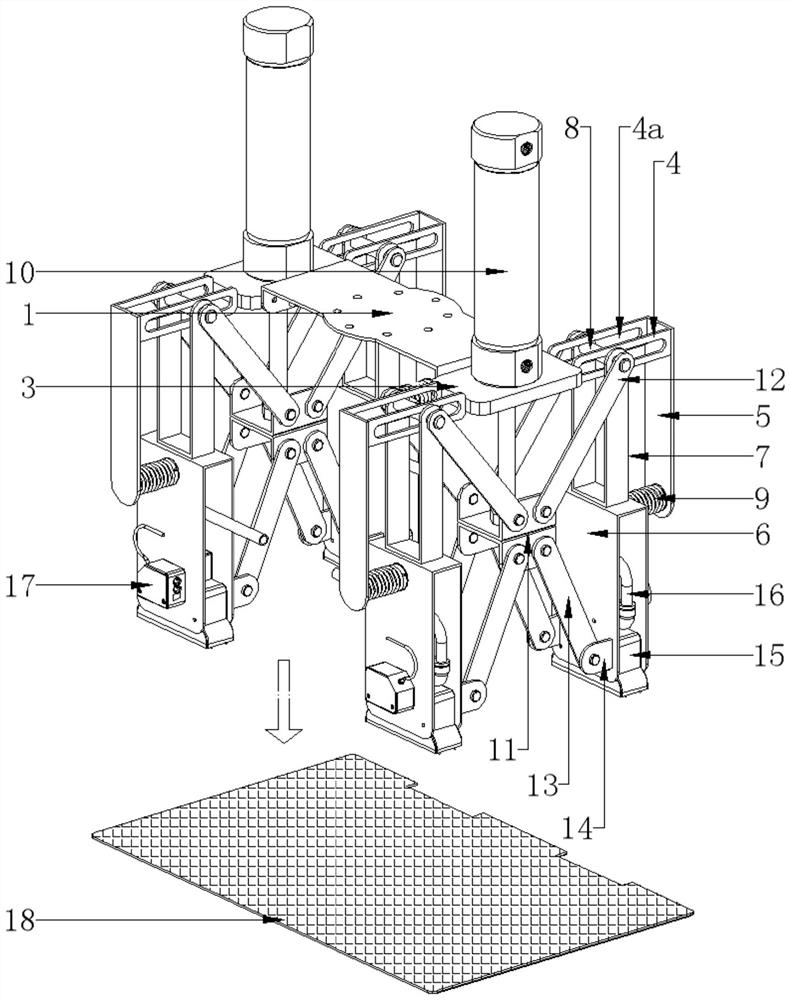

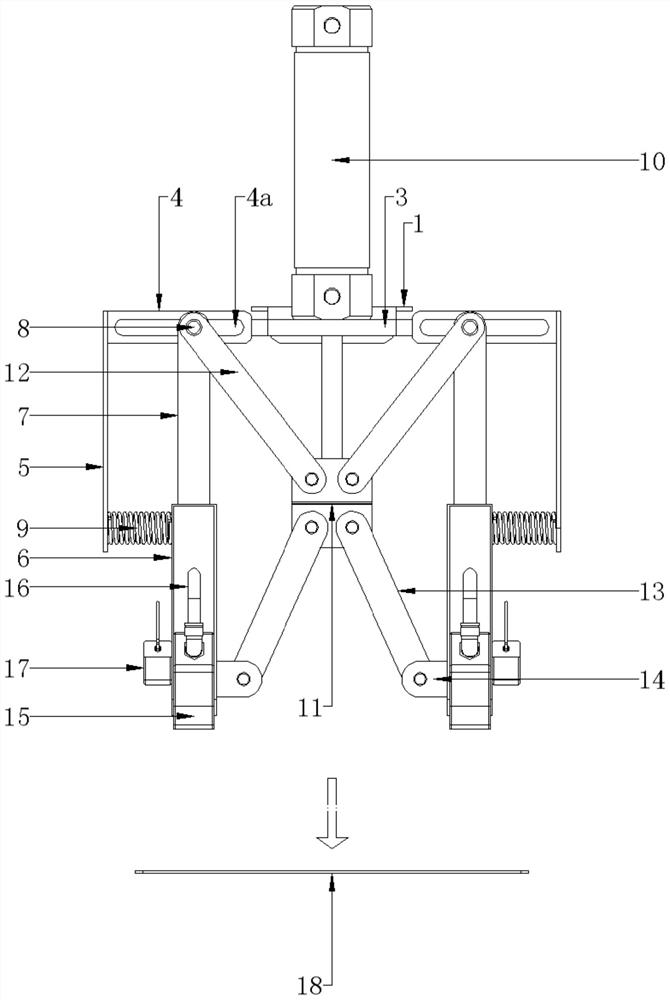

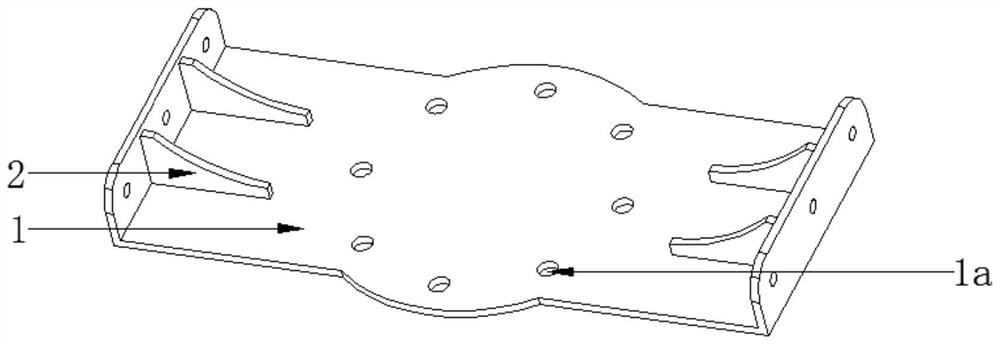

[0022] Such as Figure 1 to Figure 8 As shown, an automatic assembly device for sponge inside a cylindrical air-conditioning panel, including a connecting plate 1, a fixing plate 3, a telescopic cylinder 10 and a hinged seat 11, the connecting plate 1 is a "["-shaped structure with the opening facing downwards, and the fixing plate 3 is provided with a pair and symmetrically installed on the left and right ends of the connecting plate 1. The front and rear sides of the fixed plate 3 are symmetrically welded with a sliding bar 4 horizontally. The sliding bar 4 is provided with a rectangular sliding groove 4a. The overhanging end of the sliding bar 4 A connecting bar 5 is welded vertically, and a pair of mounting plates 6 symmetrically distributed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com