Laser marking method and system for three-dimensional complex surface

A laser marking method and technology for complex surfaces, applied in the field of laser marking methods and systems for three-dimensional complex surfaces, can solve the problems of continuous variation of surface height differences, action errors, inefficiencies, etc. on three-dimensional complex surfaces, so as to improve product quality and The effect of genuine product rate, overcoming defocusing problem and improving marking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A trajectory optimization-based robot flexible joint shaking suppression method and system technical solutions related to the present invention will be further described in detail below in conjunction with embodiments.

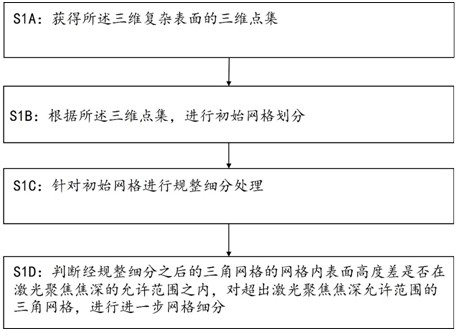

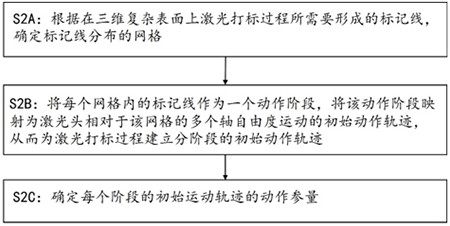

[0051]The invention provides a laser marking method for three-dimensional complex surfaces. The method of the invention is suitable for laser marking equipment that can perform marking on the three-dimensional surface of a workpiece. The three-dimensional surface is not a simple combination of several planes, nor is it A three-dimensional surface with regular changes, such as a spherical surface, can be composed of multiple planes or curved surfaces to present a three-dimensional complex surface with irregular changes. The equipment includes a fixture for holding the workpiece, and a laser head that generates and focuses a laser beam. Among them, the fixture can keep the spatial position fixed, and the laser head can move with multiple axes of freedom r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com