Coating roller replacing device of strip steel production line

A coating roller and production line technology, applied to the surface coating liquid device, coating, etc., can solve the problems of worker injury, low strip steel production efficiency, waste of time, etc., to facilitate replacement, prevent rebound, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

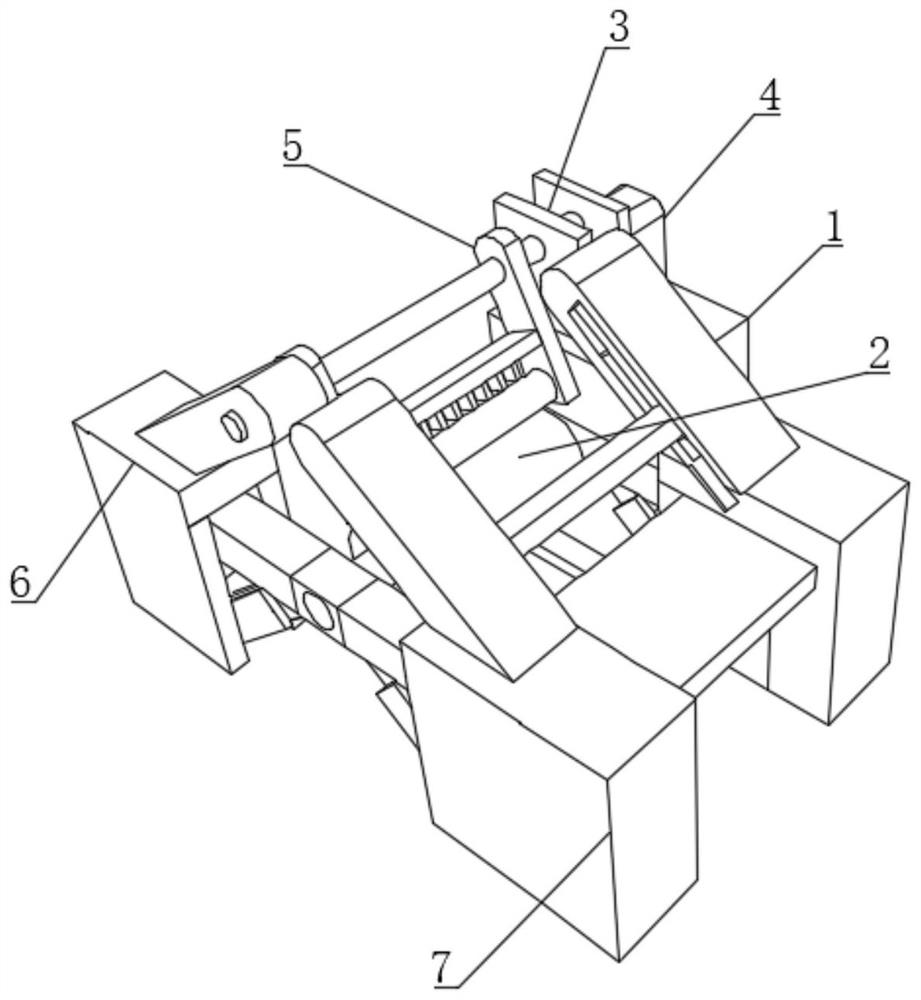

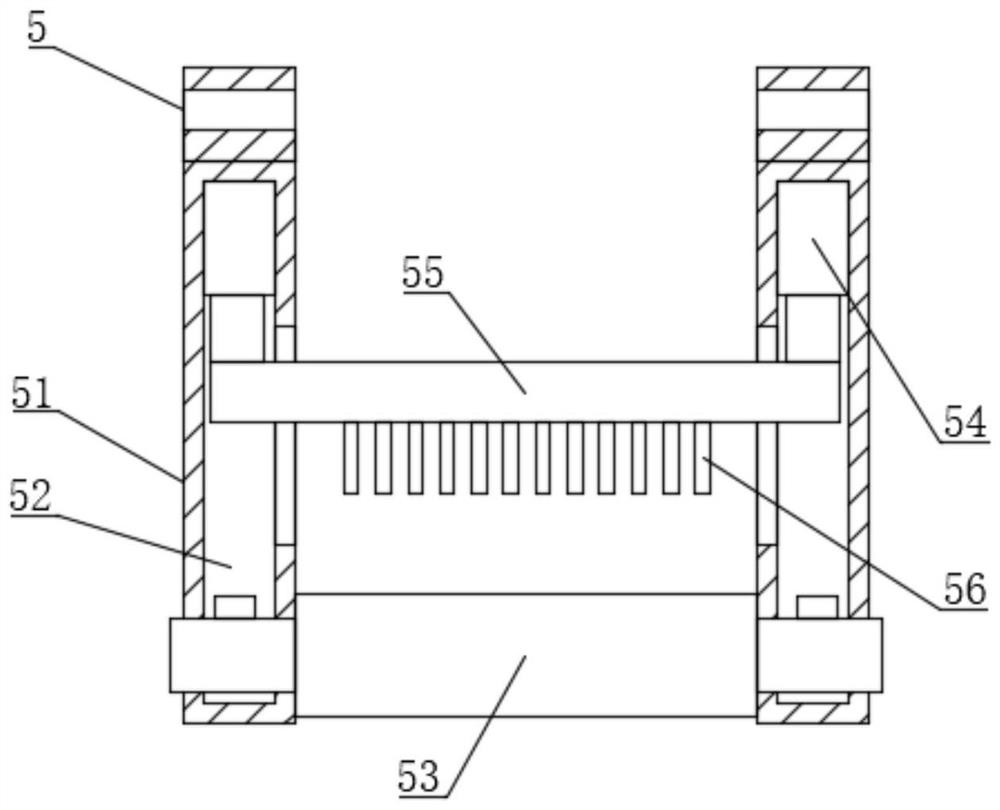

[0043] Such as Figure 1-6As shown, the present invention provides a coating roller replacement device for a steel strip production line, comprising a transmission mechanism 1, a transfer roller 2 is movably connected to one side of the transmission mechanism 1, a support frame 3 is fixedly connected to the top of the transmission mechanism 1, and the support frame One side of 3 is fixedly connected with a first motor 4, the first motor 4 extends to the outside of the support frame 3, the outer surface of the output shaft of the first motor 4 is fixedly connected with a smearing mechanism 5, and one side of the smearing mechanism 5 is movably connected with a second A support base 6, the two sides of the conveying roller 2 are movably connected with a second support base 7, the smearing mechanism 5 includes a support plate 51, one side of the support plate 51 is provided with a first chute 52, and the bottom of the first chute 52 is movable Coating roller 53 is connected, the ...

Embodiment 2

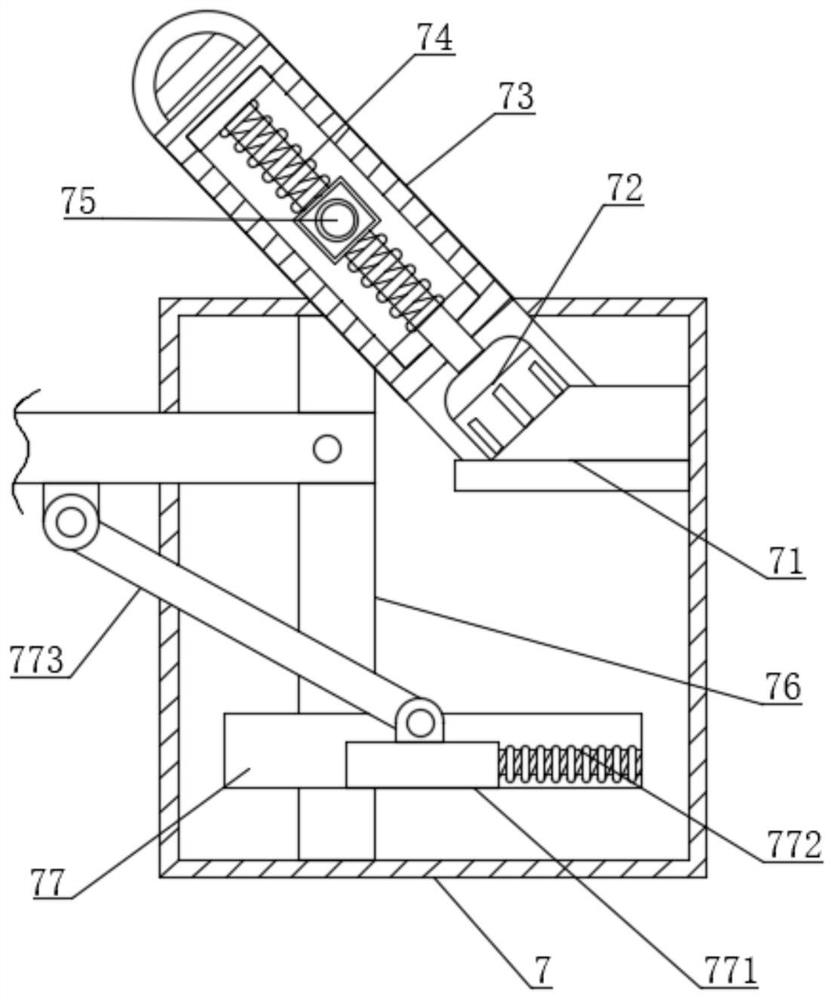

[0046] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a fixed frame 71 is fixedly installed on one side of the inner wall of the second support seat 7, and a second motor is fixedly connected to one side of the fixed frame 71 72, one side of the second motor 72 is provided with a transmission plate 73, the interior of the transmission plate 73 is provided with a transmission screw 74, the output end of the transmission screw 74 is fixedly connected with the transmission shaft of the second motor 72, the transmission screw 74 The outer surface is fixedly connected with a movable block 75, one side of the movable block 75 is fixedly connected with a connecting plate 751, the top of the connecting plate 751 is fixedly connected with a cylinder 752, and the top of the cylinder 752 is movably connected with a fixed block 753, and the top of the fixed block 753 is opened Groove 754 is arranged, and the bot...

Embodiment 3

[0049] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom of the inner wall of the second support seat 7 is fixedly connected with a T-shaped plate 76, and one end of the T-shaped plate 76 extends the first support seat 6 Inside, the inner wall side of the second supporting seat 7 is provided with a second sliding groove 77, the inside of the second sliding groove 77 is movably connected with a second sliding block 771, and one side of the second sliding block 771 is fixedly connected with a second spring 772, one end of the second spring 772 is fixedly connected to one side of the inner surface of the second slider 771, the top of the second slider 771 is fixedly connected to a connecting rod 773, and one end of the connecting rod 773 is fixedly connected to the bottom of the second sliding groove 77 .

[0050] In this embodiment, the T-shaped plate 76 improves the pressure capacity of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com