Automatic nozzle adjusting mechanism applied to fluidized bed type pulverizer

An automatic adjustment, fluidized bed technology, applied in grain processing and other directions, can solve the problem of inability to cope with the crushing of different specifications of granular materials, and achieve the effects of safe operation, improved use efficiency, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

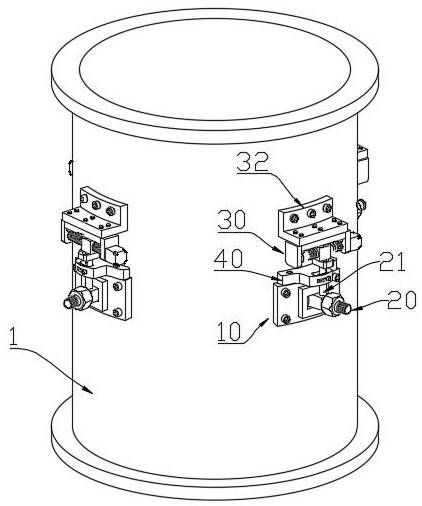

[0034] Such as figure 1 As shown, a nozzle automatic adjustment mechanism applied to a fluidized bed type pulverizer, including: a plurality of mount 10, mounting seat 10, is mounted on the side wall of the fluidized bed 1. The number of seats 10 can be set according to specific crushing requirements, which is easy to implement in those skilled in the art. The mounting seat 10 is used to rotate the fixed nozzle 20, that is, the mount 10, each nozzle 20 is adjustable to the angle of the injective airflow in the fluidized bed 1, and the nozzle can form different jet angles to form different Airflow, thereby meeting different raw material crushing requirements without replacing different fluidized beds.

[0035] Further, the present embodiment further includes a drive mechanism, and the drive mechanism is used to control the nozzle 20, that is, the angle of adjusting the nozzle 20 into the fluidized bed 1, the drive mechanism is fixed to the side wall of the fluidized bed 1.

[0036]...

Embodiment 2

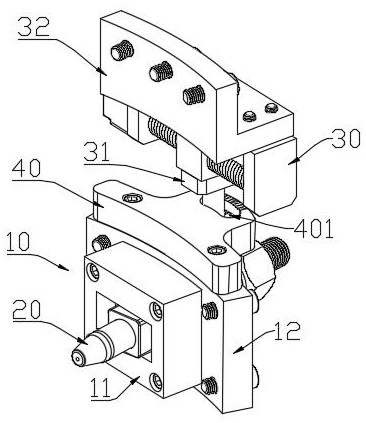

[0038] Of course, there are many structures that can rotate the nozzle 20, but from the reliability of the processes, mounting, and nozzle 20, this example gives a specific drive mechanism, such as figure 2 As shown, in the basis of the first embodiment, the drive mechanism is designed. The drive mechanism of the present embodiment includes a guide bar 21 and a straight moving mechanism 30, and the guide bar 21 is disposed vertically, one end of the guide bar 21. The nozzle 20 is fixed, and the other end of the guide bar 21 is fixed to the linear moving mechanism 30, and the linear moving mechanism 30 is used to generate a horizontal movement to drive the nozzle 20. From figure 2 It can be seen that the guide bar 21, the straight line movement mechanism 30 is provided above the nozzle 20, but from the structure of the structural design, the rotation of the nozzle 20, the guide bar 21, the linear moving mechanism 30 is also provided below the nozzle 20. Viable, does not affect the ...

Embodiment 3

[0042] The present embodiment is the substantially the same, and the present embodiment is, in this embodiment, the mount 10 has been innovative, specifically, such as image 3 , Figure 4 As shown, the mounting seat 10 includes an inner plate 11 and an outer panel 12, and the inner plate 11 is in conjunction with the outer panel 12, and a cylindrical hole is provided at a bonded hole, and the cylindrical hole is divided into two halves. Working with the bonding surface of the outer panel 12, of course, in order to prevent pressure in the fluidized bed, it is necessary to have a gasket or a sealing ring between the inner plate 11 and the outer panel 12, and the nozzle 20 has The cylindrical boss matched the cylindrical hole, and the cylindrical boss rotates into the cylindrical hole, the cylindrical boss is rotated by the nozzle 20, and the inner plate 11 and the outer panel 12 are processed in the circumferential direction of the fluidized bed 1. And the strip hole and the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com