Design method of efficient and energy-saving stirrer impeller

A high-efficiency, energy-saving, design method technology, applied to mixers with rotating stirring devices, chemical instruments and methods, mixers, etc., can solve the problems of lack of targeted impeller design, failure to achieve high efficiency and energy saving effects, and single fixed structure. , to achieve high economic benefits and promotion value, energy-saving promotion, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

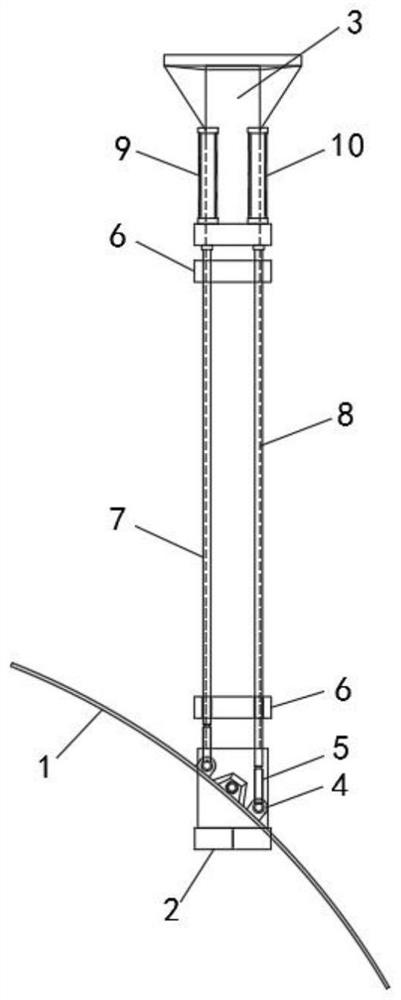

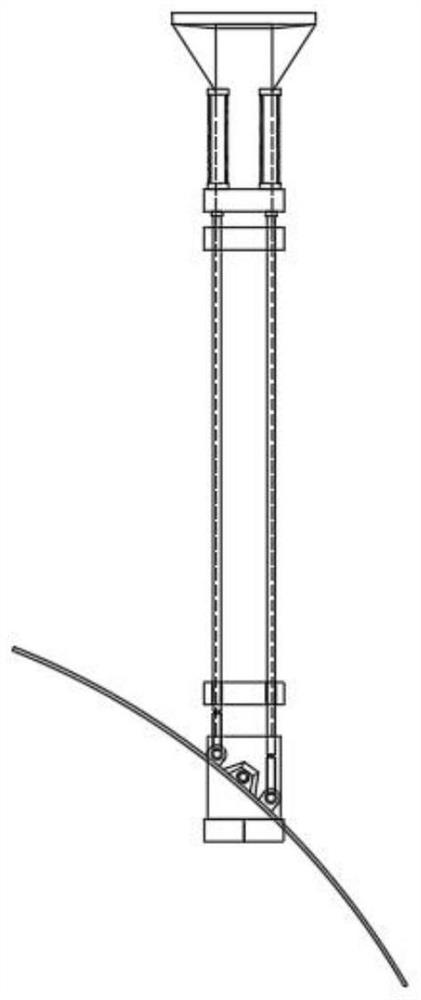

[0025] Such as figure 1 As shown, a high-efficiency and energy-saving mixer impeller design method proposed by an embodiment of the present invention is to improve the design on the existing mixer impeller structure including airfoil blade 1, wheel base 2 and rotating shaft 3. The high-efficiency and energy-saving mixer impeller The design methodology includes the following steps:

[0026] S1. Connect the airfoil blade 1 to the wheel seat 2 in rotation, and set a shaft connection seat 4 on the left and right sides of the corresponding wheel seat 2 connection end on the airfoil blade 1, and connect a movable seat 4 to the two shaft connection seats 4 respectively. axis 5;

[0027] S2. A positioning disc 6 is arranged at the upper and lower ends of the rotating shaft 3, and the first transmission rod 7 and the second transmission rod 8 respectively connected to the two movable shafts 5 are arranged longitudinally between the upper and lower positioning discs 6. Through the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com