Five-color nutritional breakfast brewing grain and preparation method thereof

A nutritious breakfast and brewing technology, which is applied in the field of five-color nutritious breakfast brewed cereals and its preparation, can solve problems such as no obvious conditioning effect on body functions, disordered life schedule, and influence on mental state, so as to improve appetite, defecation, and Stimulate appetite, good conditioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

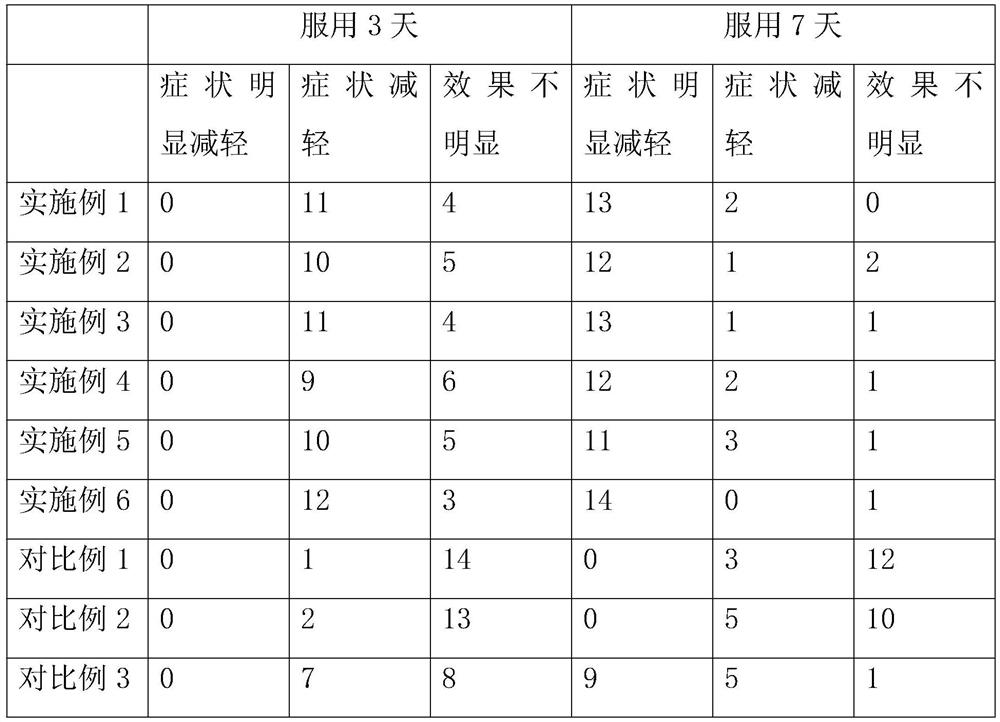

Examples

Embodiment 1-5

[0050] A five-color nutritious breakfast cereal, compounded by the following components:

[0051] Oats, coconut flour, coconut chips, brown sugar, dried eggs, mulberries, fructooligosaccharides, inulin, seaweed.

[0052] In Examples 1-5, see Table 2 for the specific input amount (unit Kg) of each component.

[0053] Table 2

[0054] Example 1 Example 2 Example 3 Example 4 Example 5 oat 20 20 20 20 20 coconut powder 4.98 4.99 5 5.01 5.02 Coconut Chips 1.98 1.99 2 2.01 2.02 brown sugar 1.48 1.49 1.5 1.51 1.52 dried eggs 2.98 2.99 3 3.01 3.02 mulberries 1.98 1.99 2 2.01 2.02 fructooligosaccharide 0.99 0.995 1 1.005 1.01 inulin 0.99 0.995 1 1.005 1.01 seaweed 0.49 0.495 0.5 0.505 0.51

[0055] In Examples 1-5, the preparation method of the five-color nutritious breakfast brewed cereal comprises the following steps:

Embodiment 6

[0061] A five-color nutritious breakfast prepared cereal, compared with Example 3, the only difference lies in:

[0062] The preparation method of the five-color nutritious breakfast brewing cereal comprises the following steps:

[0063] Step 1), cut the coconut crispy skin, brown sugar, dried eggs, mulberries, and seaweed so that the coconut crispy skin, brown sugar, dried eggs, mulberry, and seaweed can pass through a 5-mesh sieve, and then weigh each raw material according to the ratio , and then mix and stack the raw materials to obtain a premix.

[0064] Step 2), put the premix into vacuum-sealed bags, and the weight of each bag should not exceed 10kg. According to the total weight of all premixes, the weight of each bag should be evenly distributed, and all the premixes should be divided into several vacuum-sealed bags for packaging. , seal the vacuum-sealed bag and pump out the internal air, so that the air pressure in the vacuum-sealed bag is lower than 0.1MPa, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com