3D building printing leveling device and 3D building printing equipment

A leveling and building technology, applied in construction, building structure, processing of building materials, etc., can solve problems such as reducing the leveling efficiency, increasing the number of steps in the leveling process, and the surface of the scraper being no longer flat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

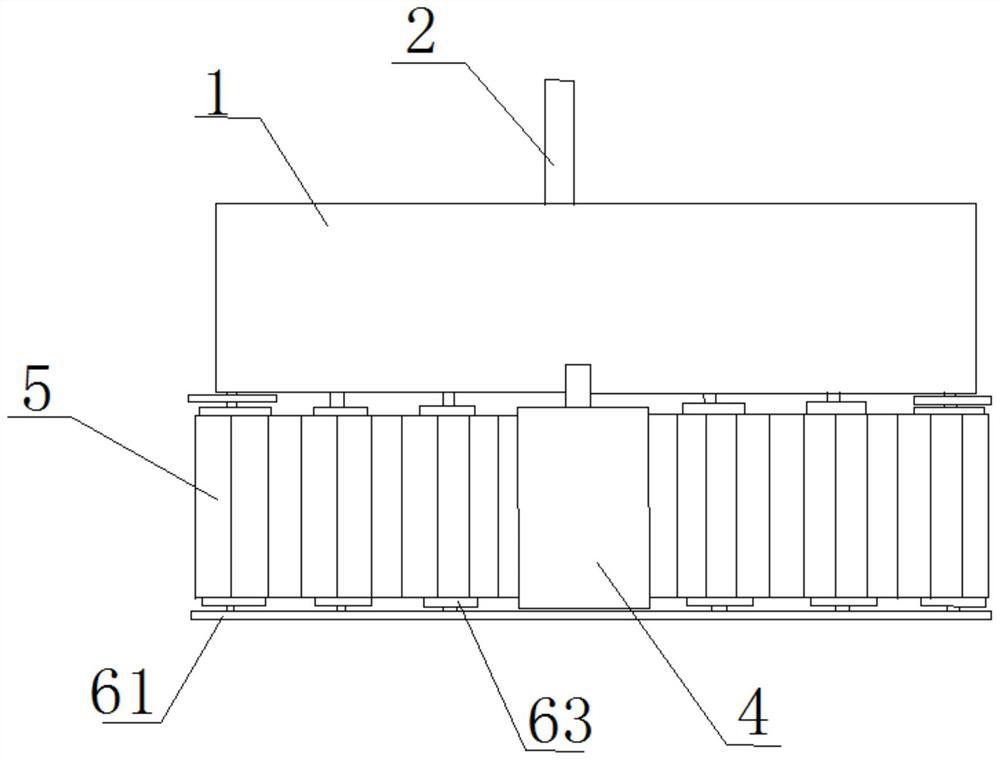

[0062] Such as figure 1 As shown, in this embodiment, the side of the smoothing drive belt 5 facing the inside of the frame 1 is located on the same vertical plane as the corresponding inner surface of the side wall of the frame 1 .

Embodiment 2

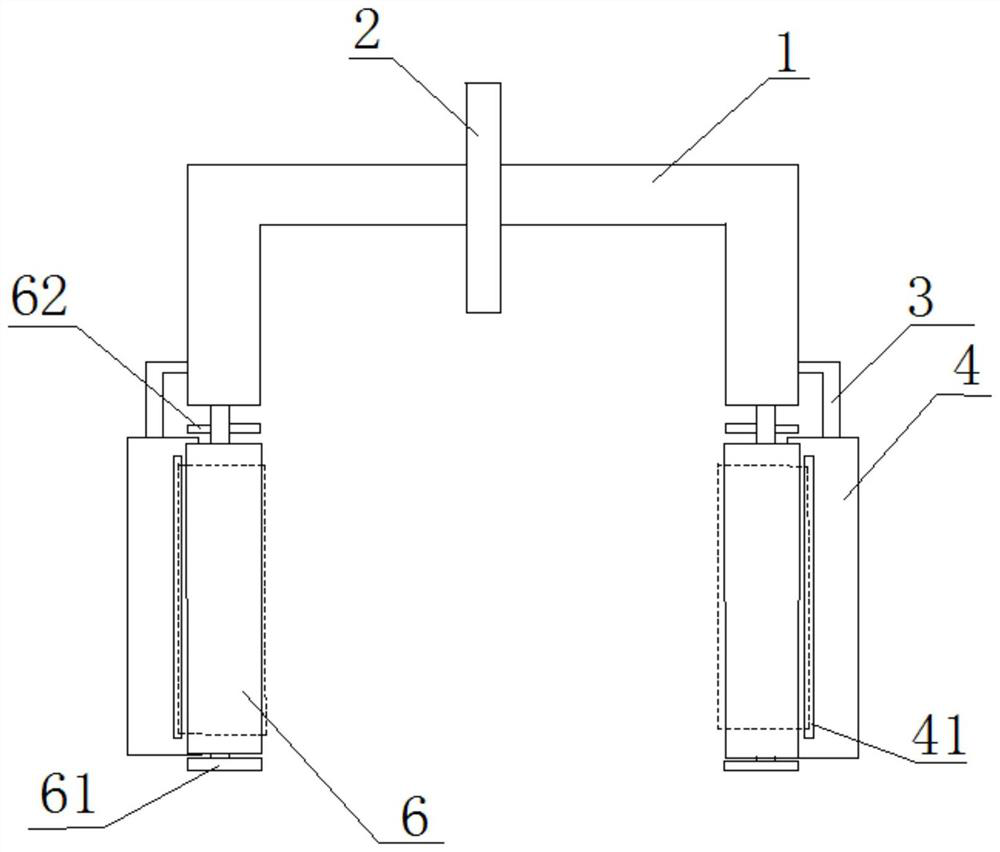

[0064] Such as Figure 4 As shown, in this embodiment, two smoothing transmission belts 5 are located on both sides outside the frame 1 . In this embodiment, the upper ends of the roller shafts of the two vertical rollers 6 in each leveling assembly are fixed on the connecting rod 3 on the same side.

[0065] In this embodiment, the connecting rod 3 is a telescopic rod that can be stretched and positioned in the horizontal direction, so that the distance between the two flat transmission belts 5 can be adjusted, so that the device of this embodiment has a wider range of applications.

Embodiment 3

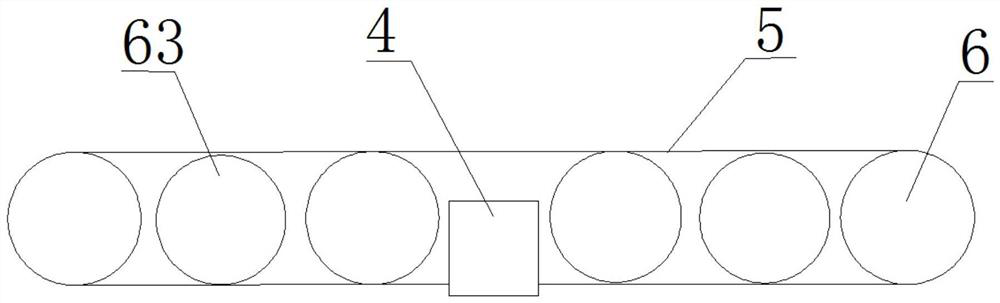

[0067] Such as Figure 5 As shown, in this embodiment, two flat driving belts 5 are located on both sides inside the frame 1 . In the present embodiment, the upper ends of the roller shafts of the two vertical rollers 6 in each leveling assembly are fixed to the lower end of the side wall of the frame 1, and the retarded liquid storage tank 4 is also fixed to the lower end of the side wall of the frame 1; A flat transmission belt 5 is arranged in the frame 1, which is beneficial to reduce the volume of the device.

[0068] In the process of printing and smoothing, since the two leveling transmission belts 5 of the present embodiment are located in the frame 1, the sprayed concrete slurry is easy to spray to the upper sides of the leveling transmission belts 5 on both sides, which is easy to vertical The rotation of the roller 6 and the rotation of the leveling drive belt 5 have an effect.

[0069] Therefore, in this embodiment, there are also two deflectors 11 arranged obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com