3D ceramic printer

A printer and ceramic technology, applied in the field of ceramic production equipment, can solve the problems of no sealing, the equipment cannot be widely used, and the ceramic printing cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

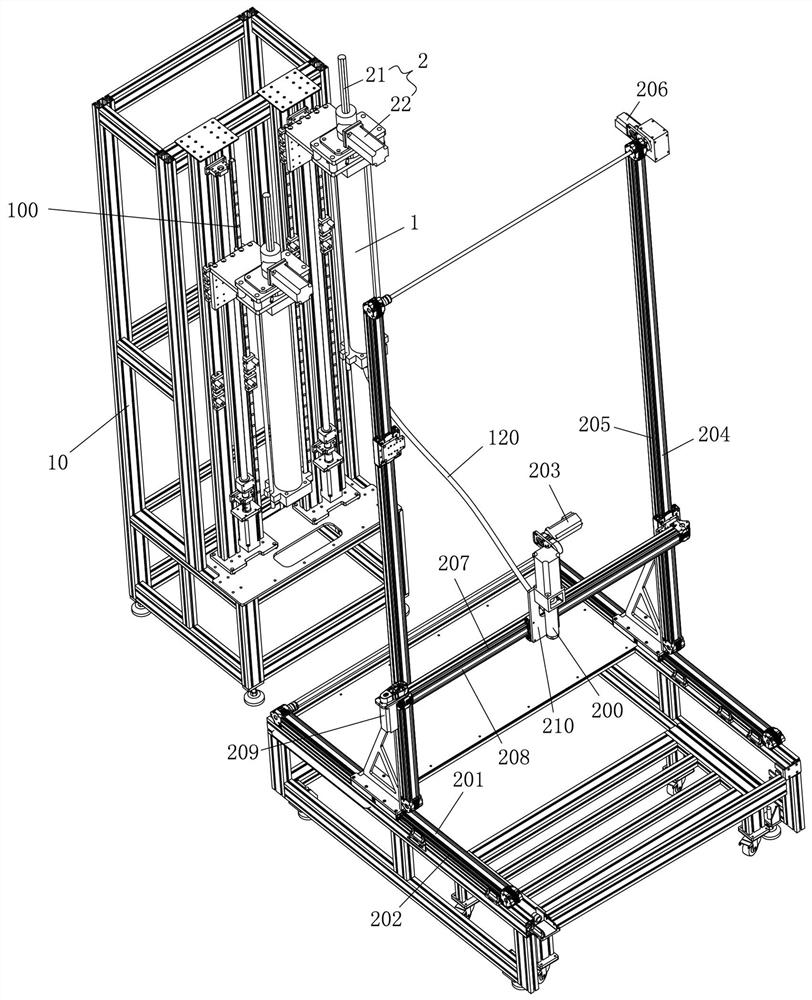

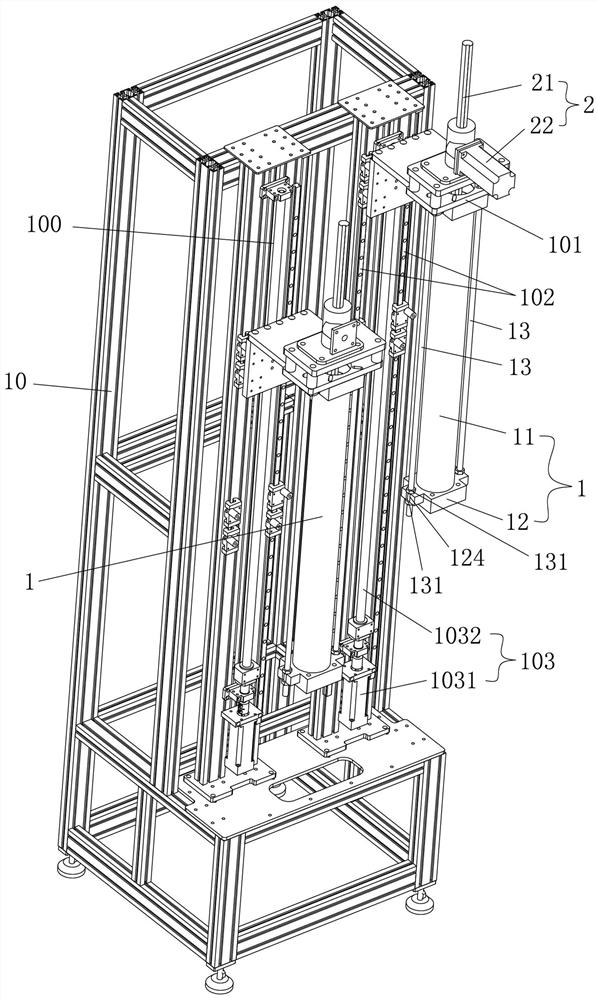

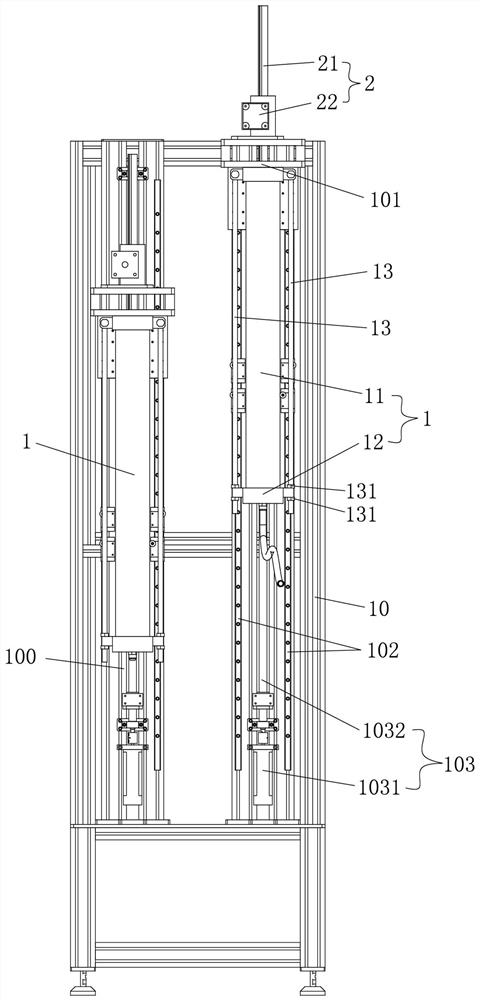

[0029] A preferred embodiment of the 3D ceramic printer of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0030] Such as Figure 1 to Figure 6 As shown, a 3D ceramic printer includes a mud feeding device 100 and a print head 200, the mud feeding device 100 includes a mud feeding frame 10, and a non-horizontally arranged columnar mud cylinder is installed on the mud feeding frame 10 1. The upper end of the mud cylinder 1 is open and the lower end is closed. A mud discharge through hole 121 is provided on the lower end of the mud cylinder 1. The mud cylinder 1 is correspondingly provided with a lifting rod mechanism 2. The lifting rod mechanism 2 includes a lifting rod mechanism 2. A rod 21 and a lifting drive mechanism 22, the lifting drive mechanism 22 is in transmission connection with the lifting rod 21, and is used to drive the lifting rod 21 to carry out lifting movement along the axial direction of the lifting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com