Concrete sandstone separator

A technology of sand and gravel separator and concrete, which is applied in the field of sand and gravel separator, which can solve the problems of reducing the screening efficiency of the separator, inconvenient cleaning, easy agglomeration and blockage of sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

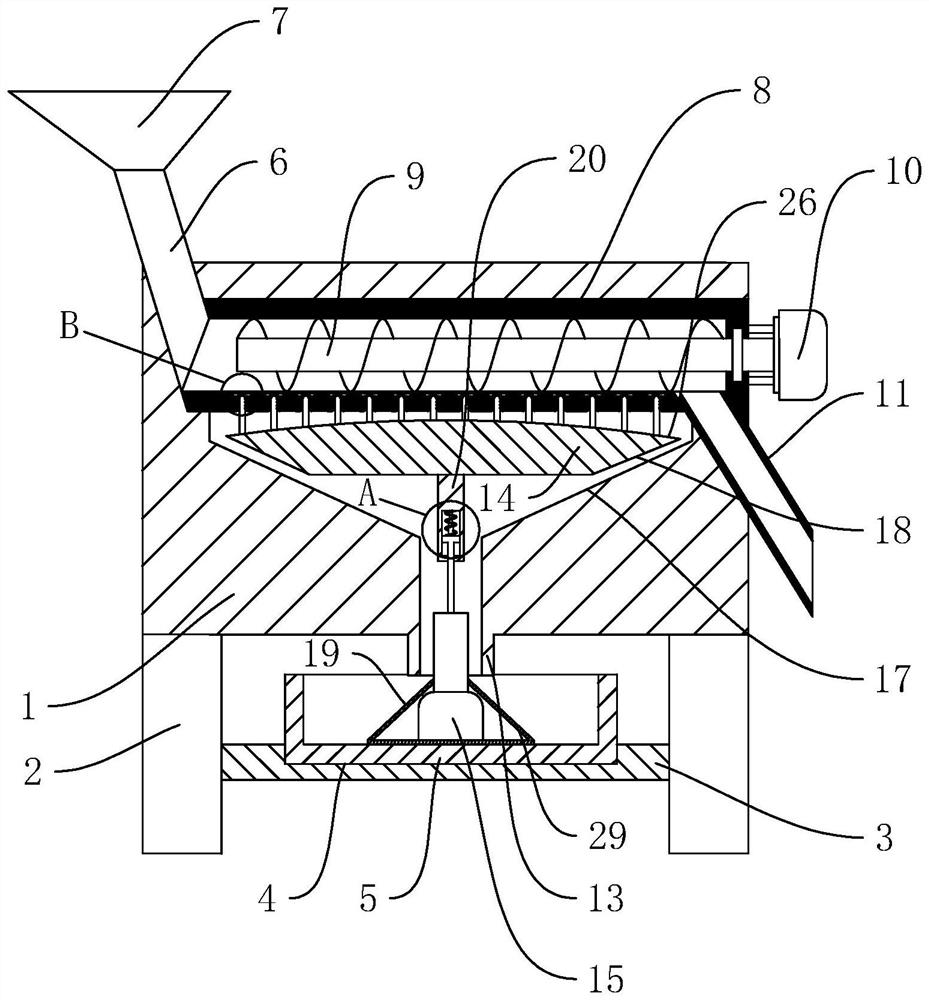

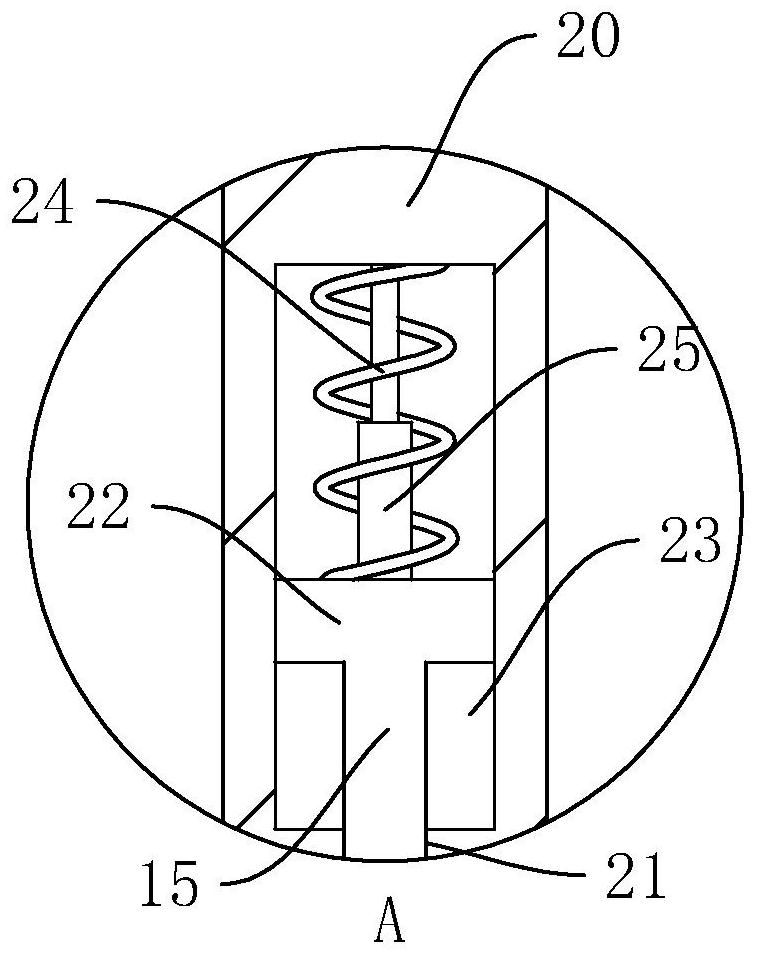

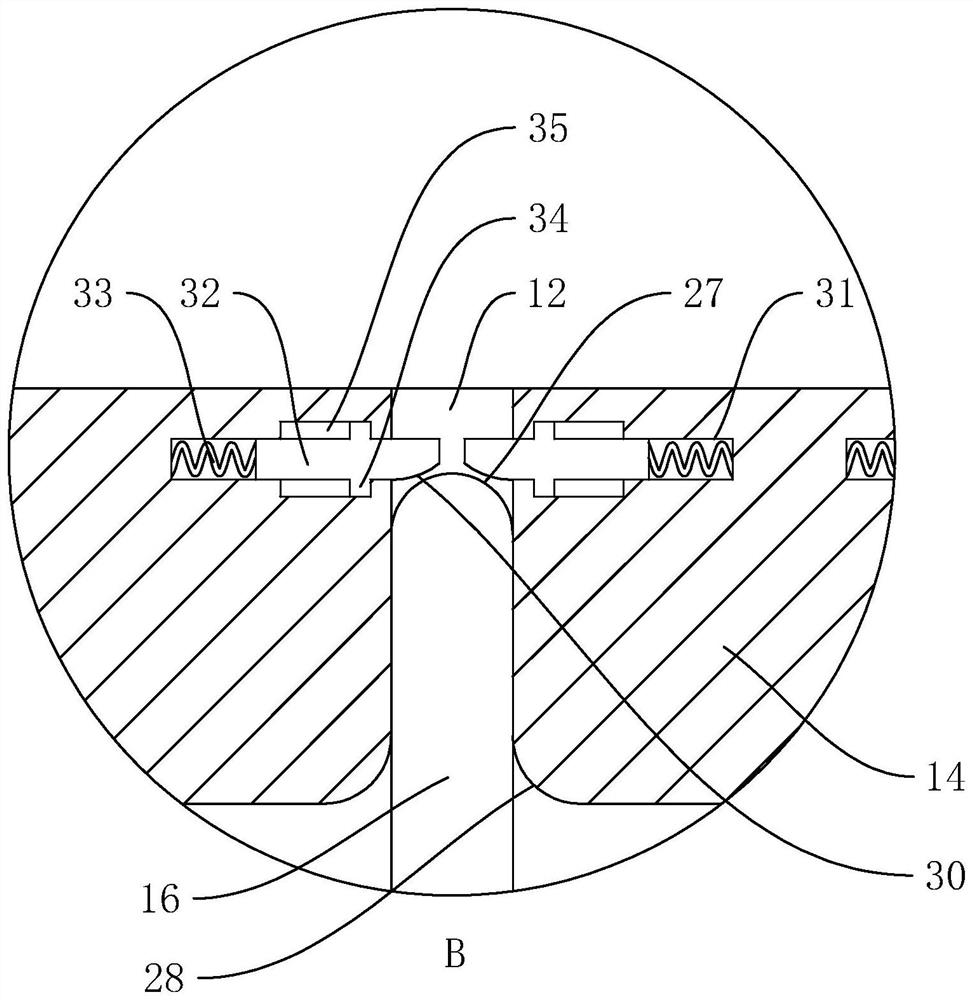

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

[0027] refer to figure 1 , figure 2 , image 3 , a concrete sand and gravel separator, comprising a box body 1, a feeding pipe 6 is arranged on one side of the box body 1, the feeding pipe 6 is arranged obliquely, and a hopper 7 is arranged at the end of the feeding pipe 6 away from the box body 1, and the box body 1 There is a separation bin 8 connected to the feeding pipe 6 inside. By pouring sand and gravel into the hopper 7, the sand and gravel are input from the hopper 7 to the feeding pipe 6 under the action of their own weight, and the sand and gravel fall along the inclined feeding pipe 6. Separation bin 8. The separation chamber 8 is rotatably connected with a screw conveying shaft 9, and the box body 1 is provided with a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com