Dynamic permeability testing device and method in oil-gas well cement paste solidification process

A test device, permeability technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve the effect of predicting the risk of gas channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

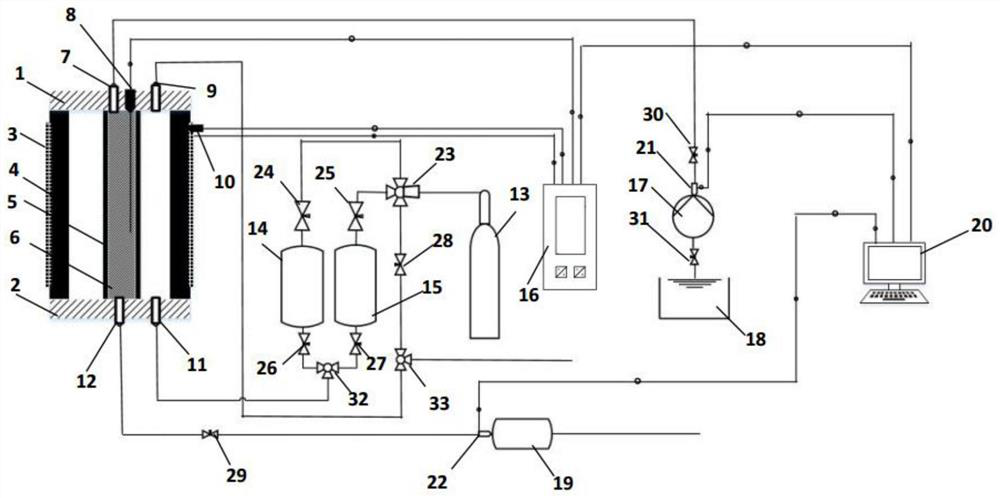

[0029] A dynamic permeability test device during the solidification process of oil and gas well cement slurry, the device includes: a sealed slurry cup, an upper end pressure control system, a lower end micro flow control system, a temperature control system, an annulus injection and drainage system, and a computer-controlled acquisition system. Among them, the sealed slurry cup is used to contain the cement slurry 6 to be tested; the upper end pressure control system is connected to the upper end of the sealed slurry cup, and is used to apply pressure on the upper end of the cement slurry 6 to be tested; the lower end micro-flow control system is connected to the lower end of the sealed slurry cup connected to control the micro-seepage of the test medium inside the cement slurry 6 to be tested; the temperature control system is used to heat and measure the temperature of the cement slurry 6 to be tested; The heating medium is discharged; and the upper pressure control system, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com