Drainage pipeline desilting device adopting horizontal directional drill

A technology for horizontal directional drilling and drainage pipes, applied in water supply installations, cleaning sewer pipes, waterway systems, etc., can solve the problems of low work efficiency, difficult long-term operation, poor working environment, etc., and achieve the effect of simple structure and convenient transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

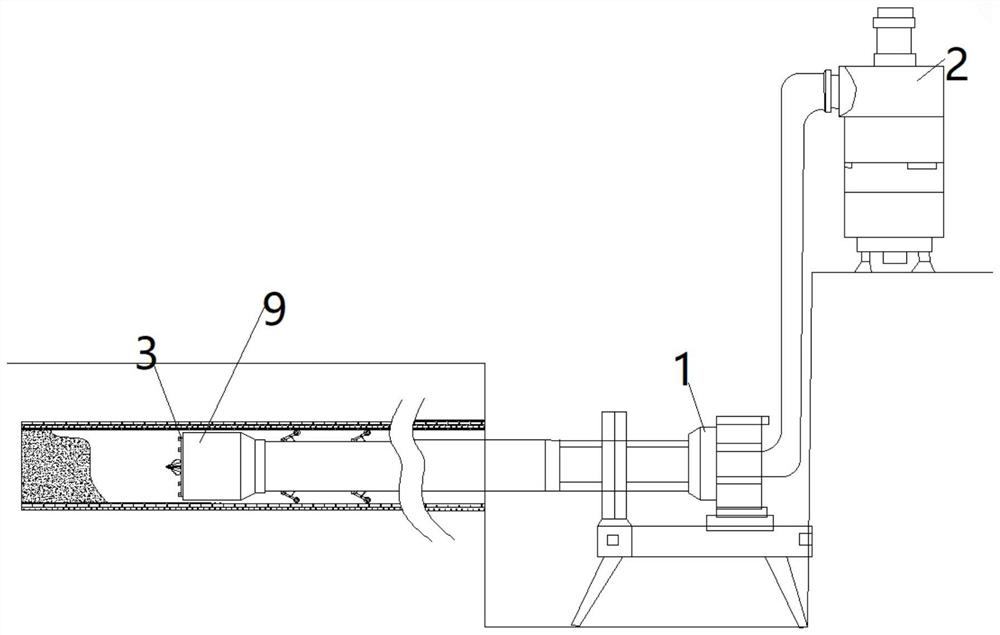

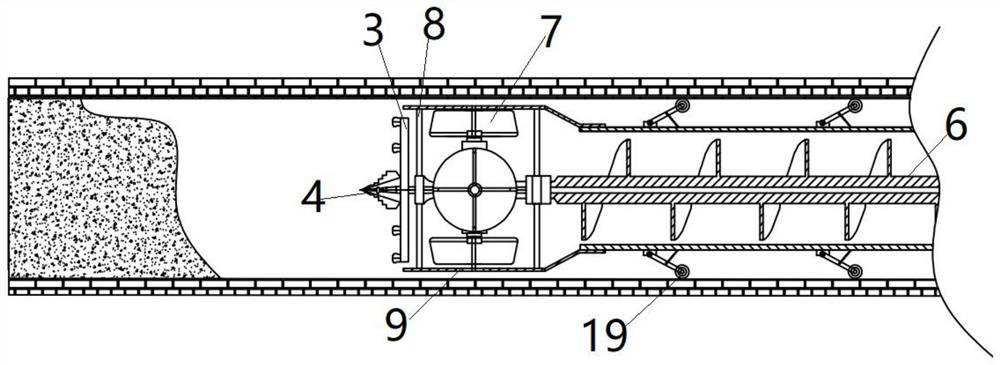

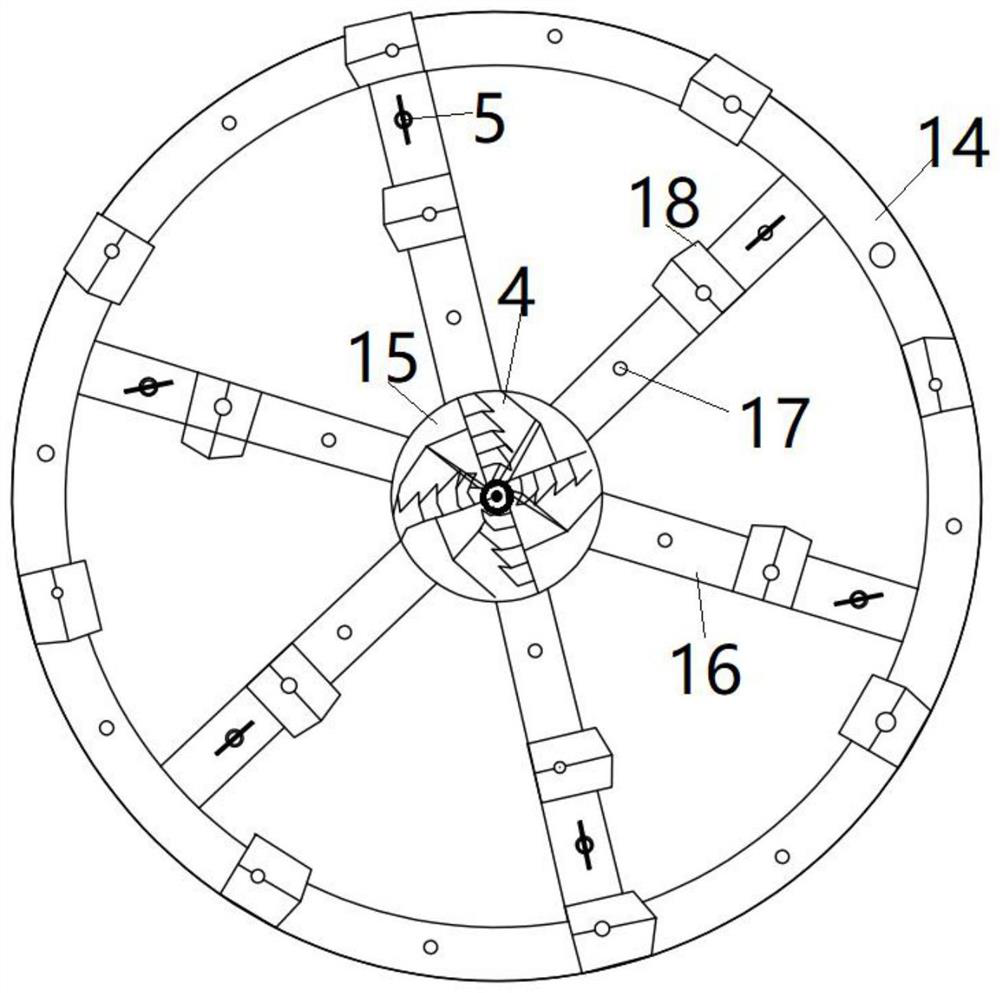

[0023] Such as Figure 1-7 As shown, the present invention discloses a drainage pipe dredging device using a horizontal directional drill, comprising a horizontal directional drilling machine 1, a high-pressure water pump 2, a sludge conveying device, a sludge stirring device, a cutting disc 3, a reamer head 4 and a high-pressure nozzle 5 , the sludge conveying device comprises a sludge conveying pipeline and a screw conveying mechanism 6, the screw conveying mechanism 6 is arranged inside the sludge conveying pipeline, the horizontal directional drilling machine 1 is driven and connected with the screw conveying mechanism 6, and the setting of the horizontal directional drilling machine 1 provides the dredging device with Driving force, the sludge stirring device is provided with stirring fan blades 7, and the stirring fan blades 7 are arranged on 4 sides. The front end of the sludge stirring device is provided with a cutting disc 3, and the cutting disc 3 includes a disc edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com