Textile silk thread anti-off wheel winding device and using method thereof

A winding device and anti-loosening technology, which is applied in the field of textile processing, can solve the problems of easy shedding of textile threads, damage of textile threads, and off-threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

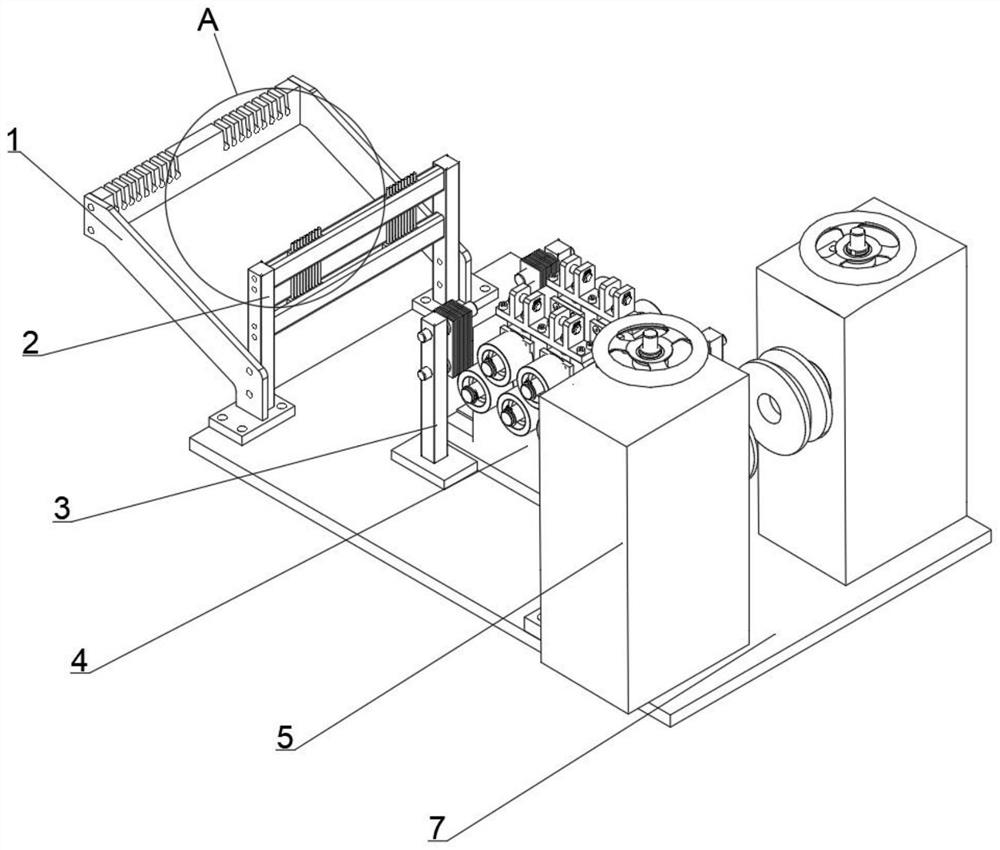

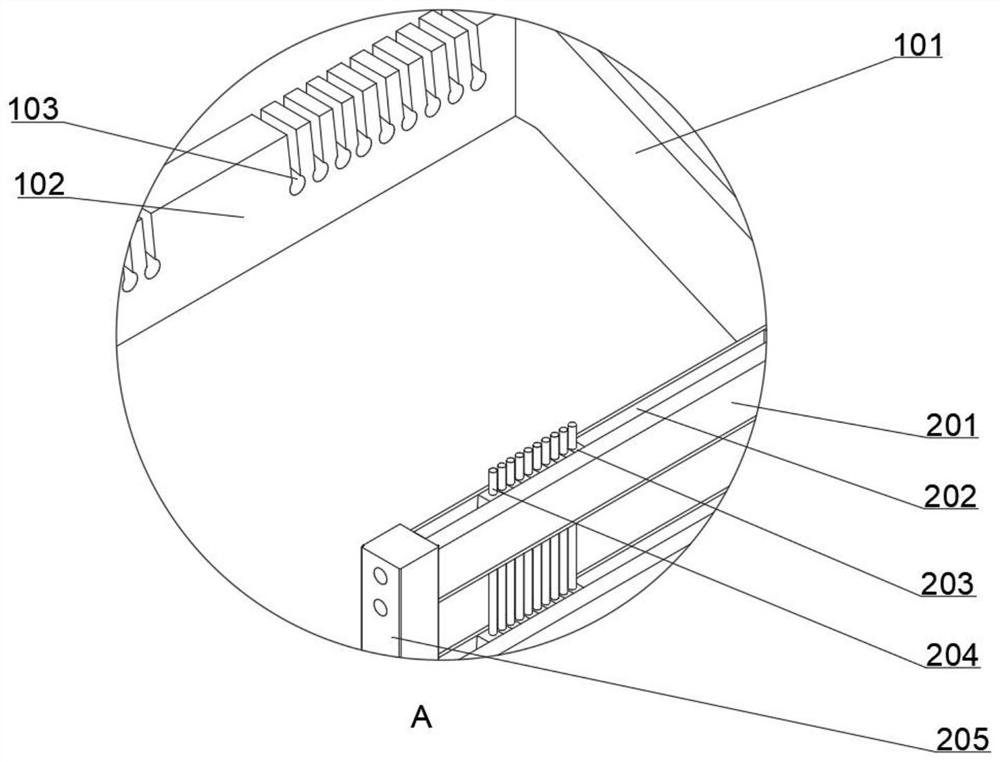

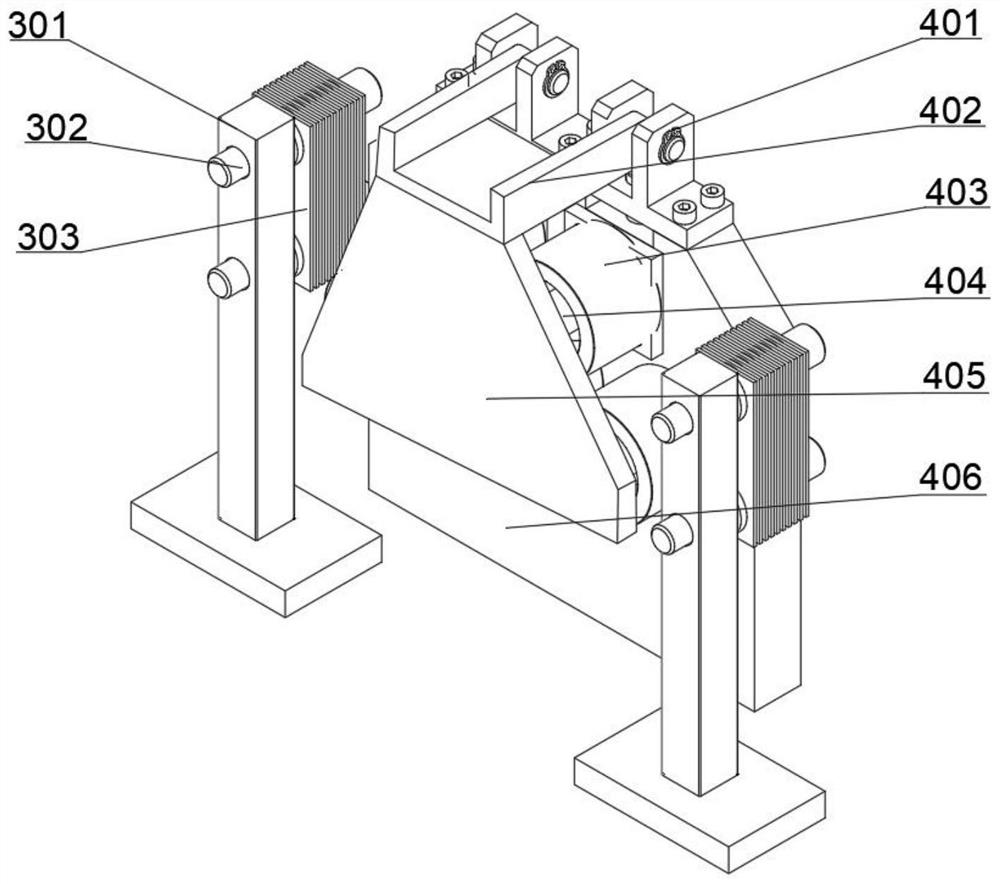

[0044] A textile thread anti-off-wheel winding device, including a wire feeding assembly 1, a wire arranging assembly 2, a plurality of wire management assemblies 3, an anti-off transmission assembly 4, a winding assembly 5, a reciprocating assembly 6, and a support plate 7, and the wire feeding assembly Component 1, cable assembly 2 and anti-off transmission component 4 are all fixedly installed on the support plate 7, multiple cable management components 3 are detachably mounted on the support plate 7, and the winding component 5 slides with the support plate 7 through the reciprocating component 6 Connection, the cable assembly 2 is placed at the rear end of the wire feeding assembly 1, a plurality of cable management assemblies 3 are placed symmetrically on both sides of the anti-off delivery assembly 4, and the winding assembly 5 is placed at the back end of the anti-off delivery assembly 4, reciprocating The component 6 is placed at the bottom of the winding component 5; ...

Embodiment 2

[0052] A textile thread anti-off-wheel winding device, including a wire feeding assembly 1, a wire arranging assembly 2, a plurality of wire management assemblies 3, an anti-off transmission assembly 4, a winding assembly 5, a reciprocating assembly 6, and a support plate 7, and the wire feeding assembly Component 1, cable assembly 2 and anti-off transmission component 4 are all fixedly installed on the support plate 7, multiple cable management components 3 are detachably mounted on the support plate 7, and the winding component 5 slides with the support plate 7 through the reciprocating component 6 Connection, the cable assembly 2 is placed at the rear end of the wire feeding assembly 1, a plurality of cable management assemblies 3 are placed symmetrically on both sides of the anti-off delivery assembly 4, and the winding assembly 5 is placed at the back end of the anti-off delivery assembly 4, reciprocating The component 6 is placed at the bottom of the winding component 5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com