Electric router shield assembly structure

An assembly structure and electric wood milling technology, applied in woodworking safety devices, wood processing equipment, manufacturing tools, etc., can solve the problems of electric wood milling shield assembly efficiency and assembly quality cannot be guaranteed, and achieve small resistance and structural size design Reasonable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

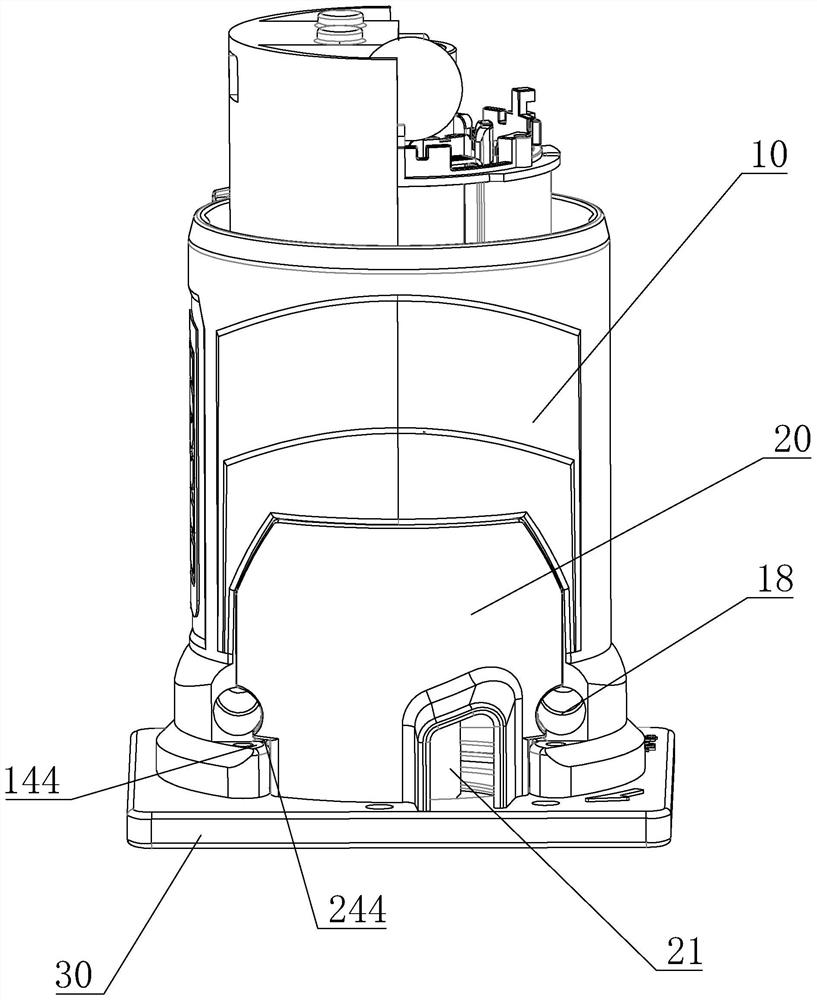

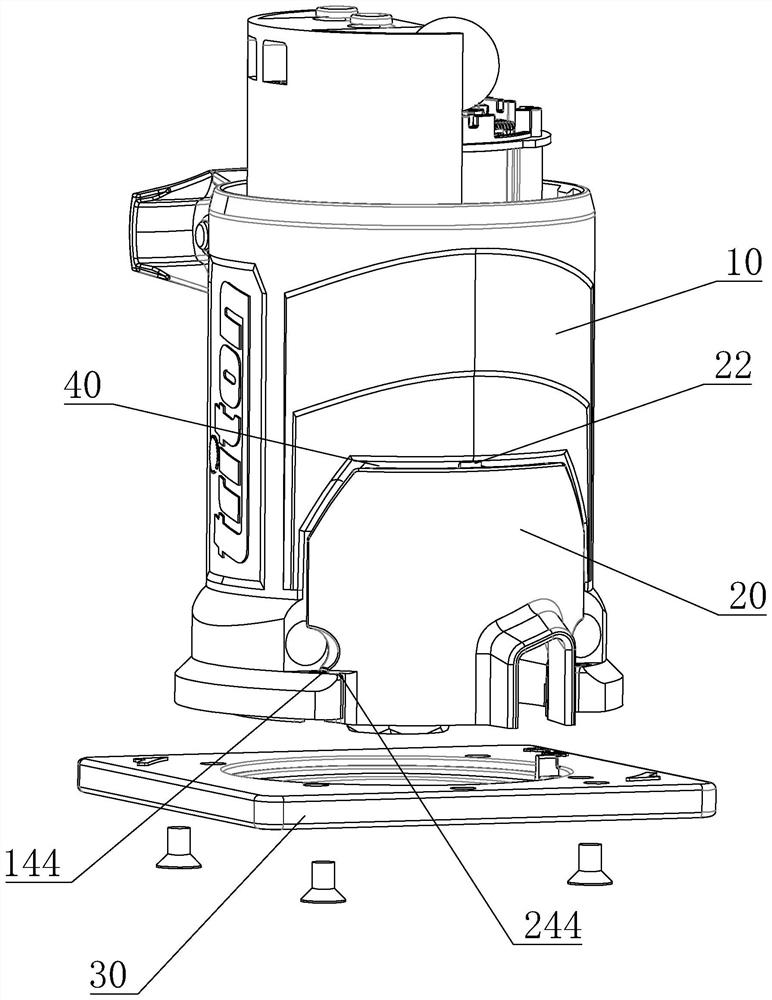

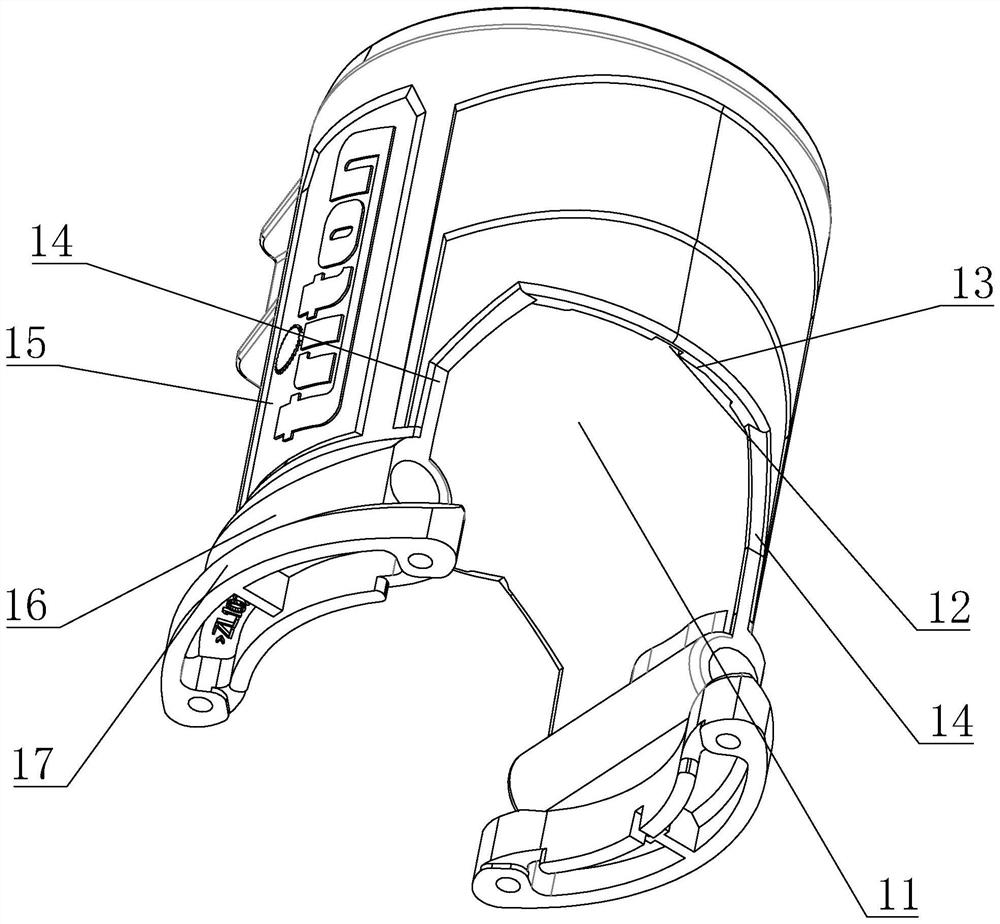

[0028] Such as Figure 1-6 As shown, this embodiment discloses an assembly structure of an electric wood milling shield, including a casing 10, a shield 20 and a bottom plate 30, and an opening extending to the bottom of the casing 10 is set on the side wall 24 of the casing 10 11. The shield 20 is assembled to the opening 11. The case 10 cooperates with the shield 20 to form an approximately cylindrical assembly cavity. The electric wood milling host is assembled in the assembly cavity. The suction hole of the suction part.

[0029] The casing 10 and the shield 20 are provided with mutually cooperating clamping components and mutually cooperating pre-assembled positioning components. The cover 20 is pre-assembled and positioned, and there is a displacement gap 40 between the shield 20 and the casing 10 for the shield 20 to move from the pre-assembly to the assembly position along the second direction, and the bottom plate 30 is supported on the casing 10 and the casing 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com