Metal sheet punching and folding composite forming machine

A metal sheet and composite forming technology, applied in the field of metal bending, can solve the problems of springback of semi-finished parts, low part pass rate, low production efficiency, etc., and achieve the effect of secondary stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

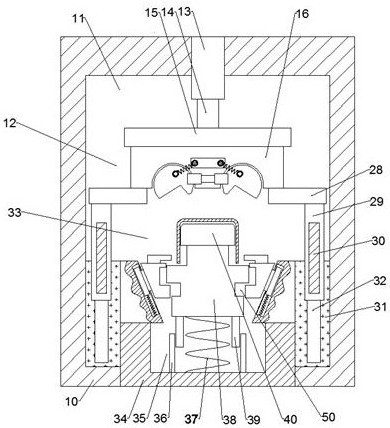

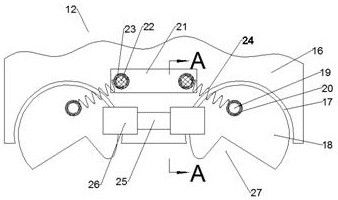

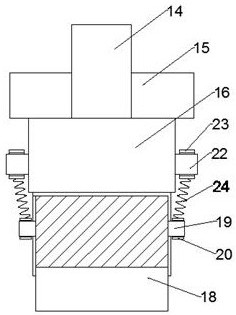

[0020] Referring to the accompanying drawings, a sheet metal punching compound forming machine according to an embodiment of the present invention includes a base 10, an operating chamber 11 is provided inside the base 10, and a vertical stamping mechanism 12 is provided inside the operating chamber 11, The vertical stamping mechanism 12 is used for downward stamping of the metal sheet; the lower end of the vertical stamping mechanism 12 is provided with a knife-inserting slider mechanism 33, and the knife-inserting slider mechanism 33 is used for composite stamping of the metal sheet in the horizontal direction Forming, the upper end wall of the operation chamber 11 is fixedly connected with a vertical stamping hydraulic cylinder 13, the lower end of the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com