Refined tea sorting machine

A sorting machine and tea technology, applied in sorting, grading, solid separation, etc., can solve problems such as ineffective effects, achieve the best separation effect, change the width, and improve the effect of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

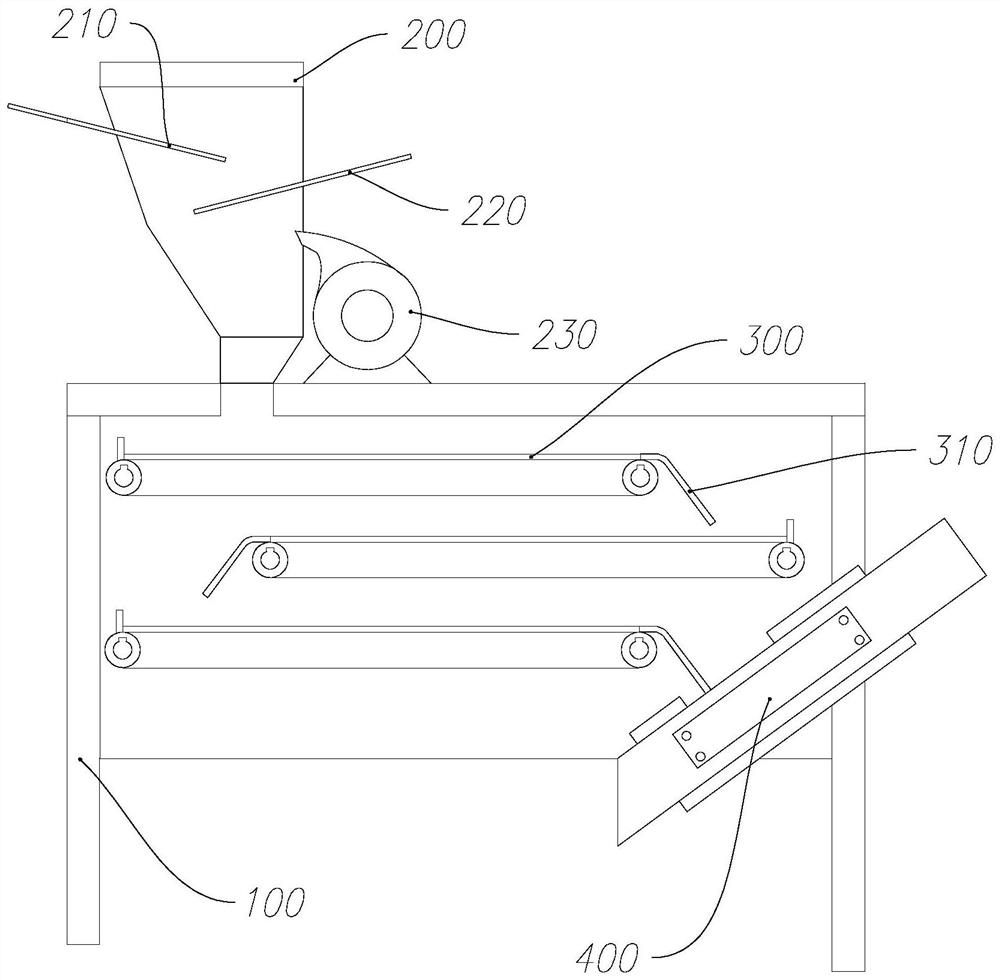

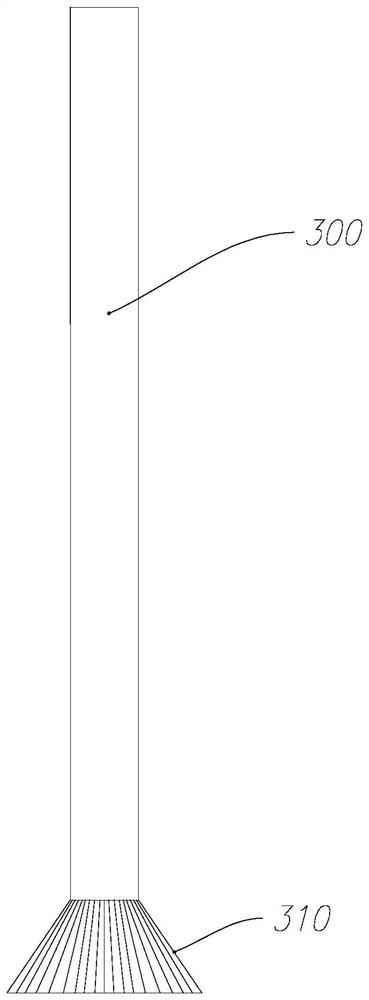

[0025] Such as Figure 1-3 As shown, this embodiment provides a sorting machine for refined tea leaves, including a frame 100, a feeding bin 200 arranged on the frame 100, and a multi-stage separation and conveying method for separating the tea balls under the feeding bin 200. mechanism, and a color sorting device 400 located at the end of the multi-stage separation and conveying mechanism for screening the separated tea leaves.

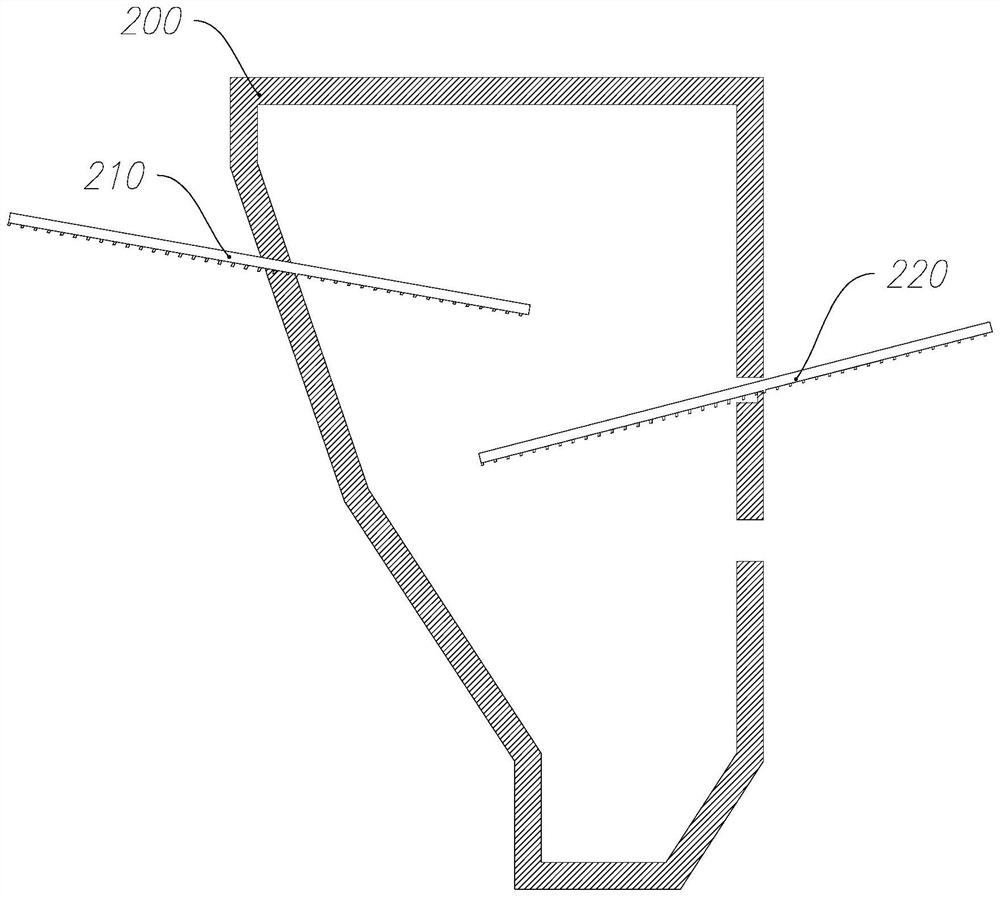

[0026] The feeding bin 200 is provided with a blanking baffle 210 for controlling the feeding speed and preventing the entry of air dust and impurities, a blower 230 for blowing the tea leaves away, and for preventing the tea leaves from being blown away when the blower 230 is working. The wind blocking baffle 220 is blown out from the feeding bin 200 . The blanking baffle 210 and the wind blocking baffle 220 are respectively arranged on two opposite side walls of the feeding bin 200 and the blanking baffle 210 is located above the wind blocking baf...

Embodiment 2

[0038] Such as Figure 6 As shown, another embodiment of the refined tea sorting machine is shown. The main difference between this embodiment and Embodiment 1 is that the three conveyor belts 300 in this embodiment do not partially overlap in the vertical direction. Together, but in twos perpendicular to each other, this setting can make the tea balls not only impact at different speed differences, but also impact the lower conveyor belt 300 at different angles during each falling process, thereby increasing the scattered possible.

[0039] The rest of the structures and features are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com