Accumulator floor assembly for motor vehicle

A technology of bottom components and accumulators, applied in vehicle components, electric vehicles, vehicle energy storage, etc., can solve problems such as the lack of functions at the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

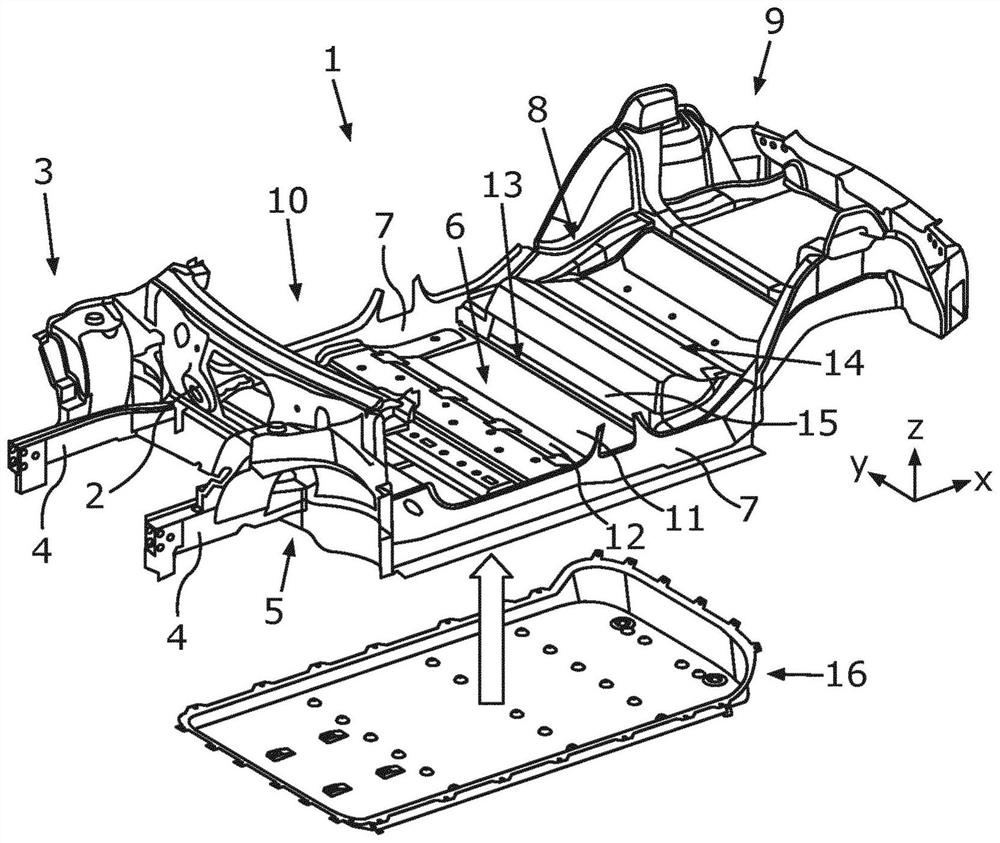

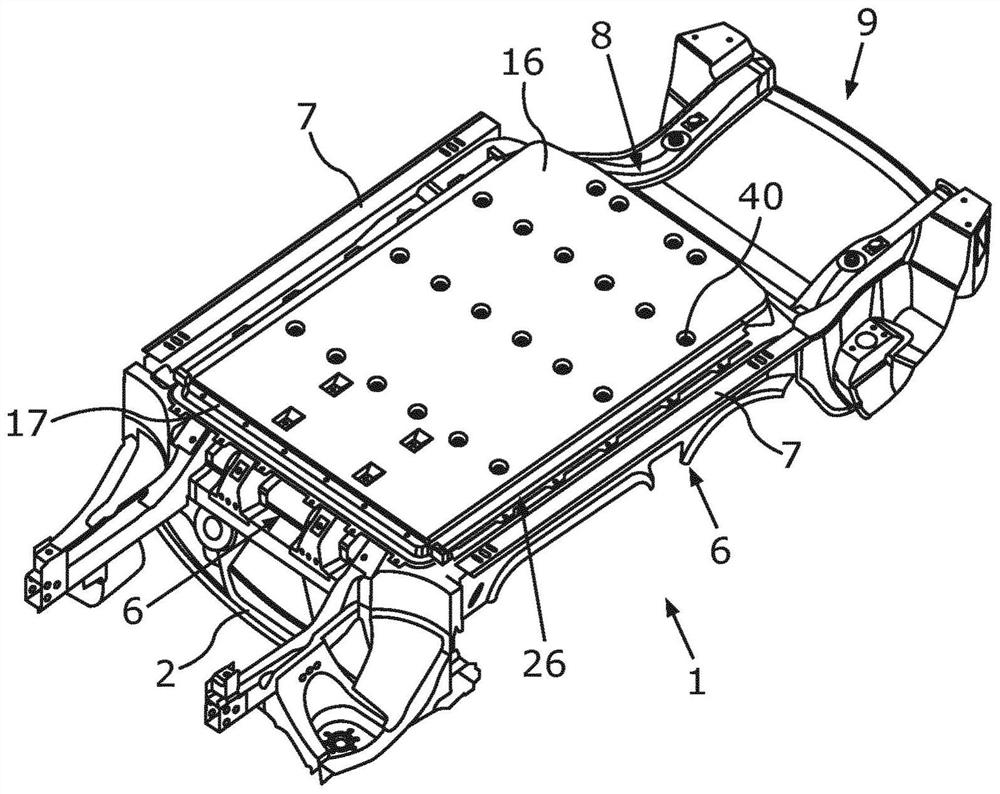

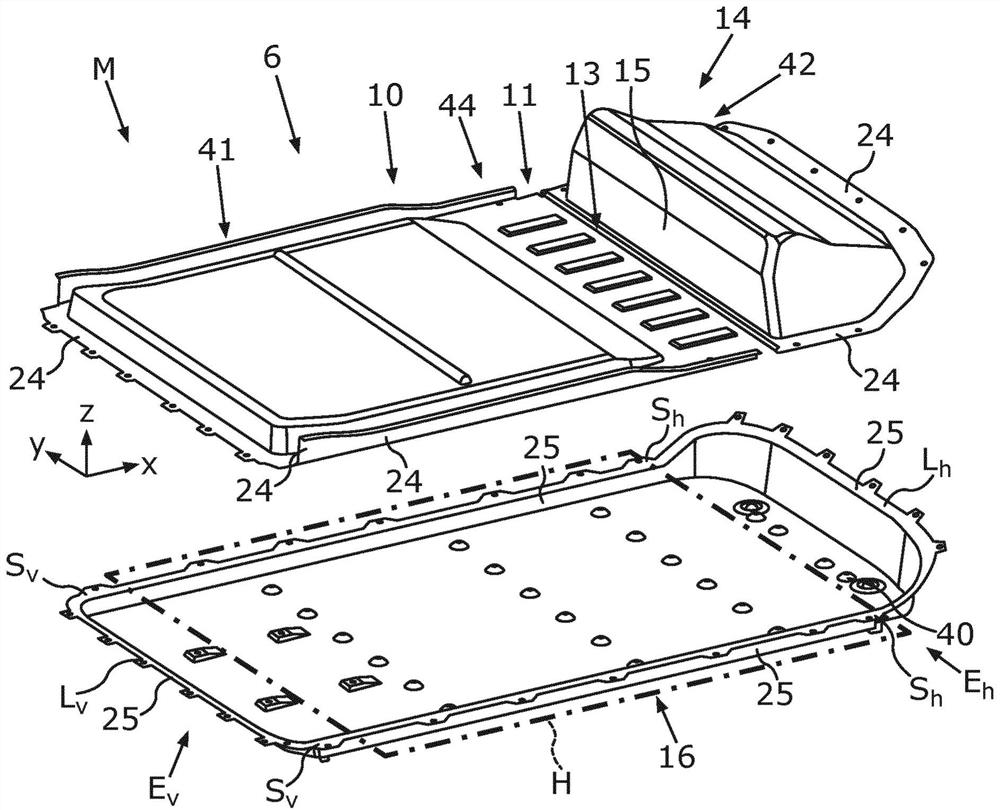

[0028] figure 1 and 2A motor vehicle body 1 for an electrically operable motor vehicle is shown in a perspective exploded view and a perspective bottom view, respectively. The motor vehicle can be, for example, such a motor vehicle with a fully electric drive (BEV) or a hybrid vehicle (PHEV) which, in addition to a purely electric drive, also has an internal combustion engine. In the present case, the motor vehicle body 1 generally comprises a front end wall 2 of the passenger compartment, which adjoins forwardly a front structure 3 , which includes, for example, a corresponding longitudinal member / engine mount 4 of the central longitudinal member plane. The end wall 2 transitions rearwardly into a transition region 5 , which for example includes an obliquely extending pedal base or the like and transitions into a vehicle floor 6 , which delimits the passenger compartment downwards and extends to—on the outside in the longitudinal direction of the vehicle direction and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com