Method for manufacturing electrode plate of deep-circulation small valve-regulated lead-acid storage battery

A lead-acid battery and a production method technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems such as the reduction of the number of sheets and the thickness of the separator, the reduction of the battery reaction area, the impact on the battery performance, etc., so as to improve the cycle life and slow down the loosening and softening speed. , the effect of shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

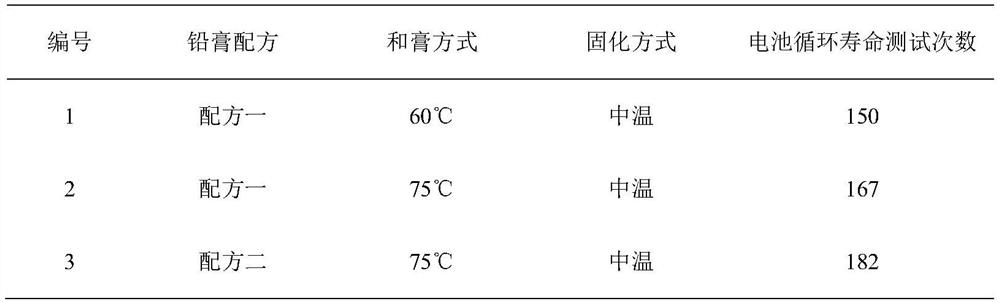

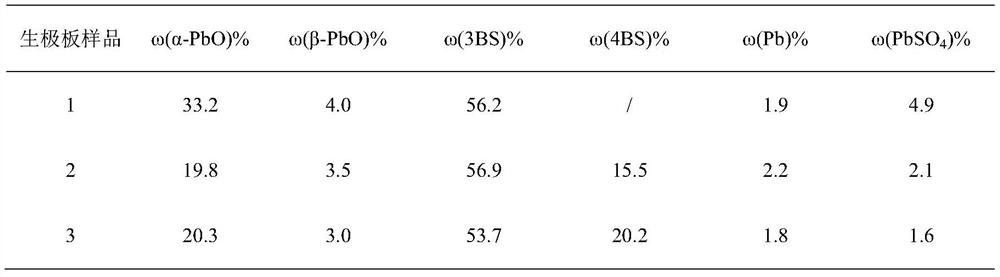

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

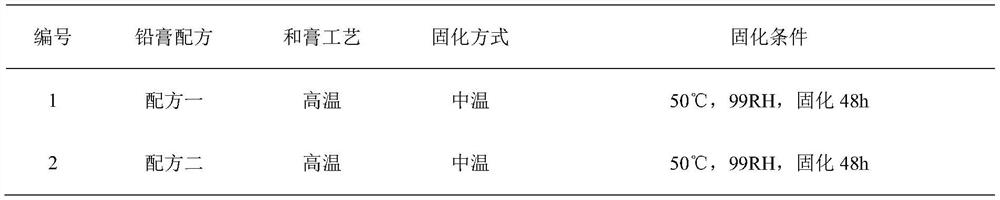

[0015] A method for manufacturing a plate of a small deep-cycle valve-regulated lead-acid battery, step 1: preparing raw materials; formula of lead paste for the plate: lead powder, short chemical fibers, and 4BS seed crystals;

[0016] Step 2: High temperature mixing paste: put the plate lead paste formula in step 1 into the paste mixing machine and dry stir for 5 minutes, then add pure water, and the time for mixing pure water into lead powder is 2 minutes; after adding pure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com