Scheduling method for collaborative operation of multiple intelligent devices in intelligent warehouse

A technology of smart devices and warehouses, which is applied in the field of scheduling of collaborative operations of multiple smart devices in smart warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, and the following examples are only used to illustrate the technical solutions more clearly, but not to limit the protection scope of the present invention. The present invention mainly illustrates the train of thought of the present invention with the example of four-way shuttle car, hoist, and conveyor in the three-dimensional warehouse.

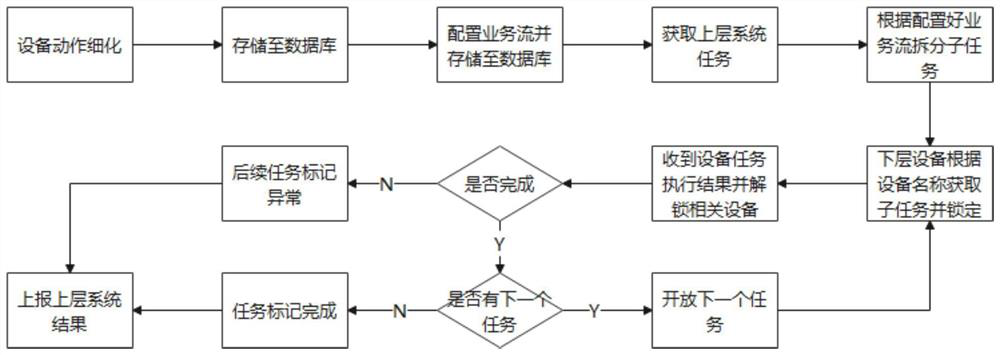

[0025] Such as figure 1 As shown, it is a scheduling method for intelligent warehouse multi-smart equipment collaborative operation of the present invention, and the specific steps are as follows:

[0026] Step 1, the device action is refined and stored in the first configuration file or database;

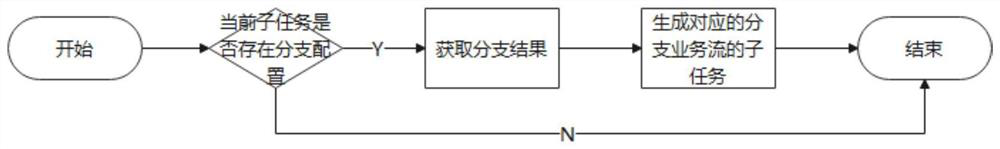

[0027] Step 2. Obtain the executable actions after the disassembly number from the first configuration file or database, combine the executable actions according to the actual business flow, and complete the action configuration of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com