Optical lens and electronic equipment

An optical lens and lens technology, applied in optics, optical components, instruments, etc., can solve the problems that affect the miniaturization characteristics of the lens and increase the production cost of the lens, and achieve the effect of low cost and large central angular resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

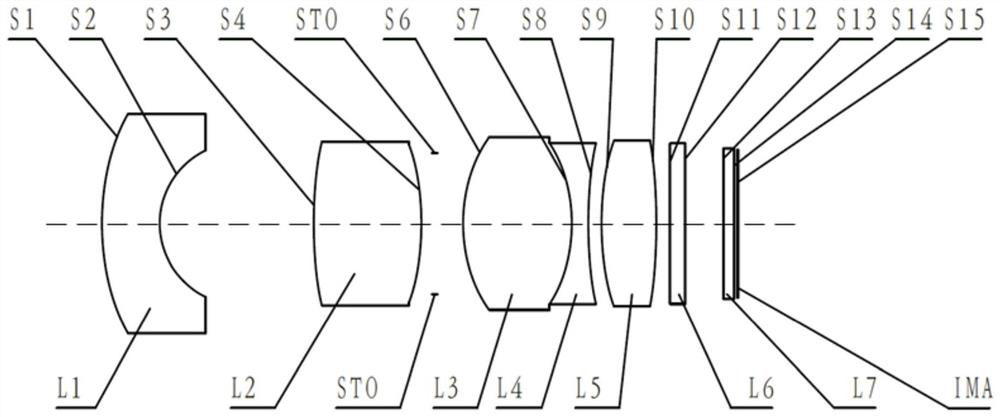

[0116] Refer to the following figure 1 An optical lens according to Embodiment 1 of the present application is described. figure 1 A schematic structural diagram of the optical lens according to Embodiment 1 of the present application is shown.

[0117] like figure 1 As shown, the optical lens sequentially includes a first lens L1 , a second lens L2 , a third lens L3 , a fourth lens L4 and a fifth lens L5 along the optical axis from the object side to the image side.

[0118] The first lens L1 is a convex-concave lens with negative refractive power, the object side S1 is convex, and the image side S2 is concave. The second lens L2 is a biconvex lens with positive refractive power, the object side S3 is convex, and the image side S4 is convex. The third lens L3 is a biconvex lens with positive refractive power, the object side S6 is convex, and the image side S7 is convex. The fourth lens L4 is a biconcave lens with negative refractive power, the object side S7 is concave, ...

Embodiment 2

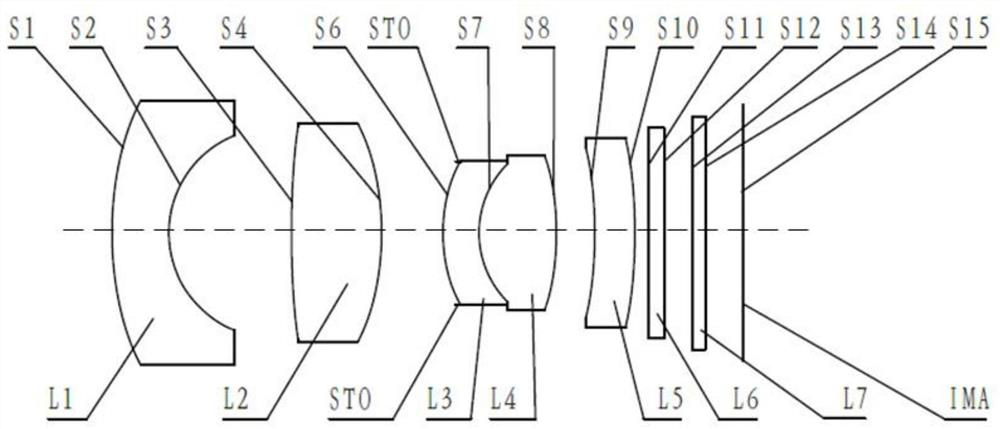

[0131] Refer to the following figure 2 An optical lens according to Embodiment 2 of the present application is described. In this embodiment and the following embodiments, for the sake of brevity, descriptions similar to those in Embodiment 1 will be omitted. figure 2 A schematic structural view of the optical lens according to Embodiment 2 of the present application is shown.

[0132] like figure 2 As shown, the optical lens sequentially includes a first lens L1 , a second lens L2 , a third lens L3 , a fourth lens L4 and a fifth lens L5 along the optical axis from the object side to the image side.

[0133] The first lens L1 is a convex-concave lens with negative refractive power, the object side S1 is convex, and the image side S2 is concave. The second lens L2 is a biconvex lens with positive refractive power, the object side S3 is convex, and the image side S4 is convex. The third lens L3 is a convex-concave lens with negative refractive power, the object side S6 is...

Embodiment 3

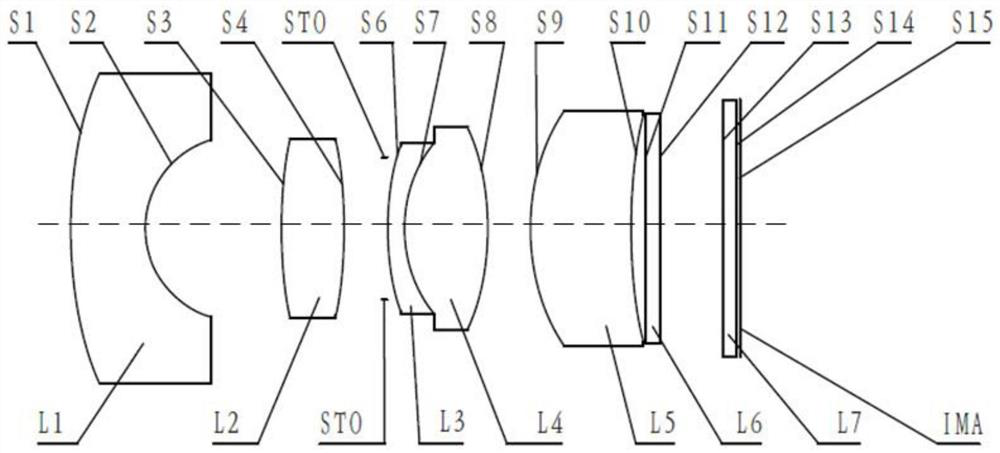

[0142] Refer to the following image 3 An optical lens according to Embodiment 3 of the present application is described. image 3 A schematic structural diagram of an optical lens according to Embodiment 3 of the present application is shown.

[0143] like image 3 As shown, the optical lens sequentially includes a first lens L1 , a second lens L2 , a third lens L3 , a fourth lens L4 and a fifth lens L5 along the optical axis from the object side to the image side.

[0144] The first lens L1 is a convex-concave lens with negative refractive power, the object side S1 is convex, and the image side S2 is concave. The second lens L2 is a biconvex lens with positive refractive power, the object side S3 is convex, and the image side S4 is convex. The third lens L3 is a convex-concave lens with negative refractive power, the object side S6 is convex, and the image side S7 is concave. The fourth lens L4 is a biconvex lens with positive refractive power, the object side S7 is conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com