Relative torsion angle measuring device based on timestamp

A technology for measuring devices and torsion angles, which is applied in the directions of measuring devices, torque measurement, power measurement, etc., can solve the problem that the relative torsion angle cannot be integrated, and achieve the effect of satisfactory accuracy and simple and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

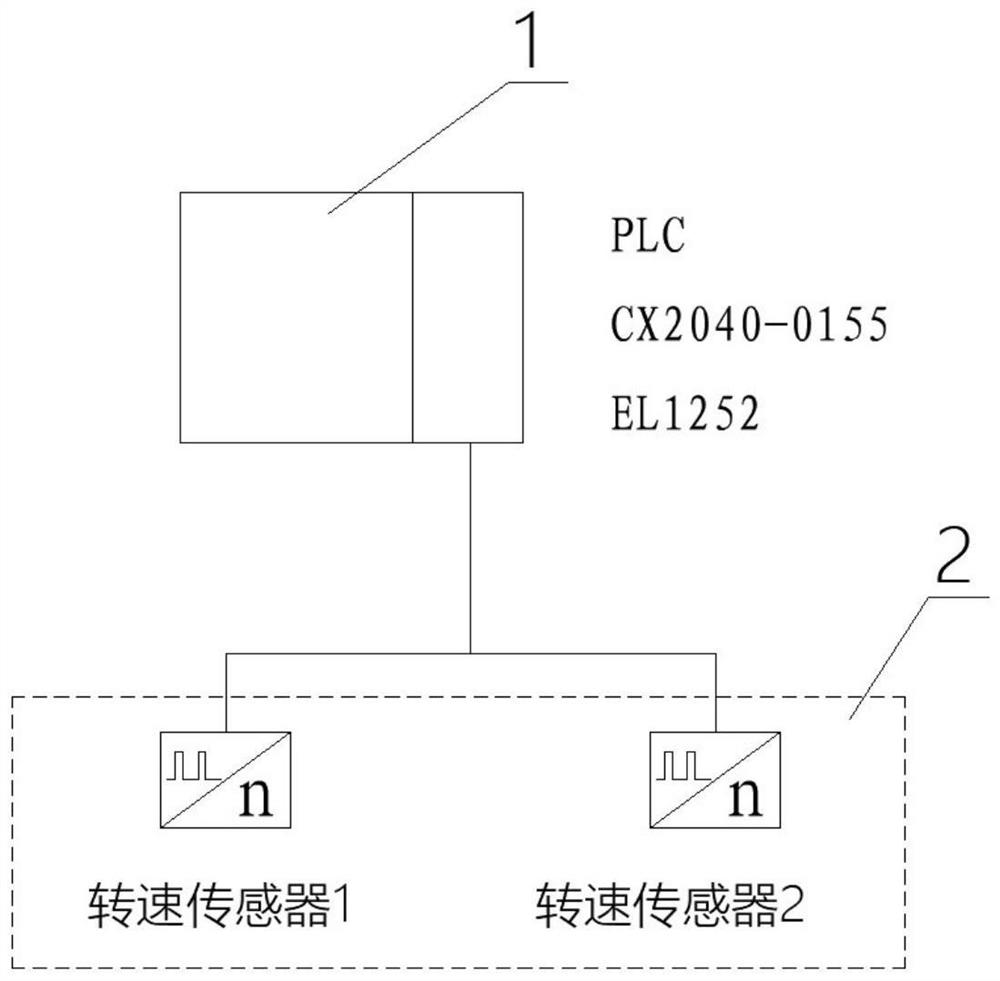

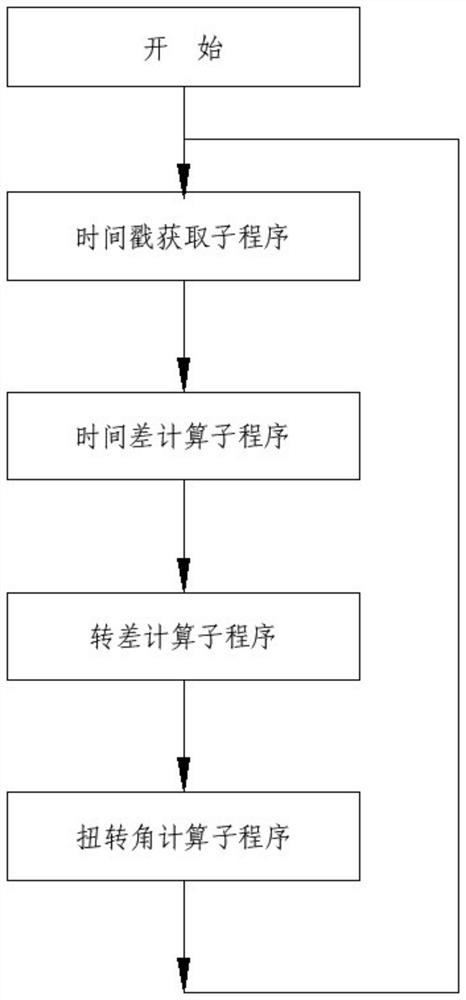

[0013] like figure 1 As shown, a relative torsion angle measurement device based on time stamp involved in this embodiment, which integrates the torsion angle measurement function, realizes a relative torsion angle measurement method based on time stamp, including a PLC control module 1 and a speed sensor 2, The signal of the rotational speed sensor 2 enters the PLC control module 1, and the PLC module 1 is used to complete the acquisition of pulse signal frequency and time stamp and calculate the time stamp difference and rotational speed difference, and then calculate the relative torsion angle.

[0014] As an embodiment of the present invention, the PLC control module 1 includes Beckhoff CX2040-0155 and EL1252, and the CX2040-0155 is the acquisition and calculation control core of the entire system. The controller, the EL1252 module in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com