Method for treating water seepage of jet grouting pile

A treatment method and technology of rotary grouting piles, which can be applied in the direction of sheet pile walls, buildings, protective devices, etc., can solve the problem of limited pilot hole space, unsatisfactory water sealing effect of ultra-high pressure rotary grouting piles and occlusal piles, ultra-high pressure rotary grouting piles, etc. The construction quality of the water-stop curtain puts forward higher requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

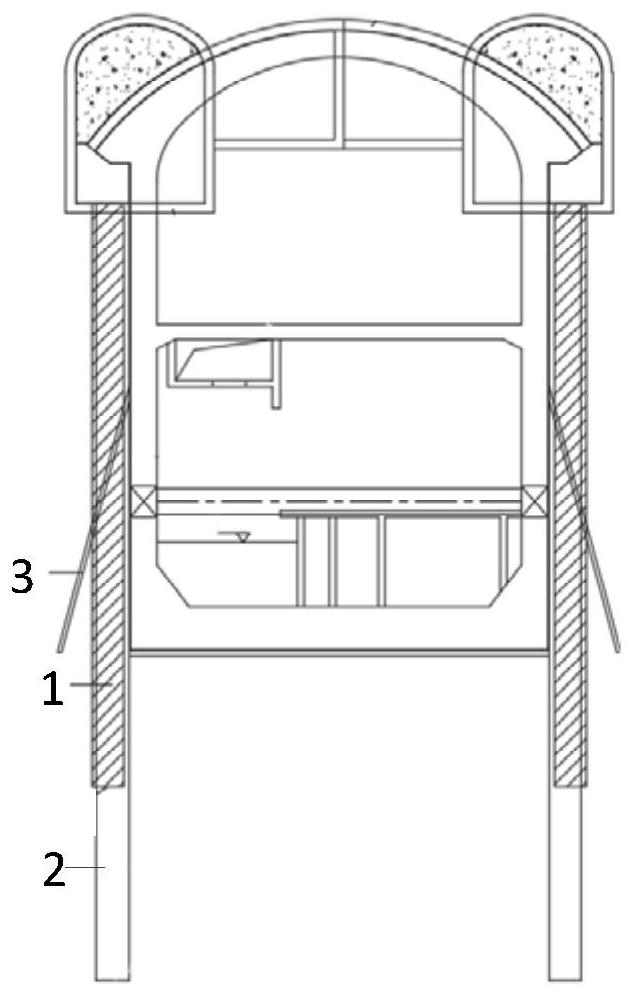

[0044] Refer below figure 1 and figure 2 To describe the water seepage treatment during the construction of the subway station.

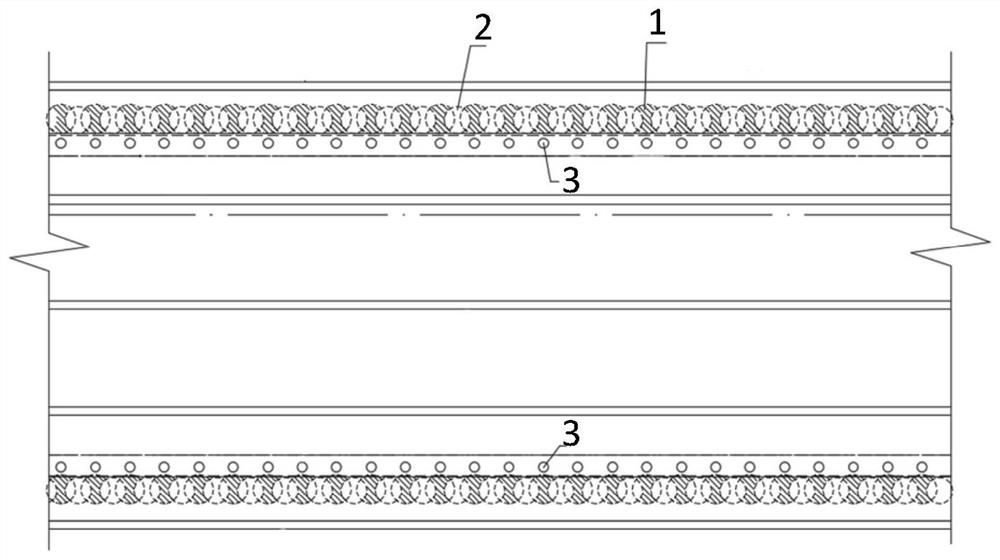

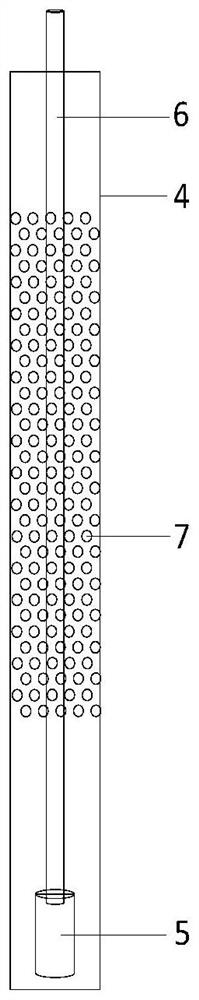

[0045] In the construction site of the middle plate of the subway, after the excavation of the first layer of earthwork on the platform layer of the subway is completed, when the ultra-high pressure rotary grouting pile 1 is defective or the pile body seeps due to the loose engagement with the bored pile 2, according to the water seepage point and its water gushing degree, combined with the site construction conditions, determine the location of the required dewatering well 3, the dewatering depth is 5-10m, and the inclination angle is 15-30°; select several PVC dewatering well pipes with a diameter of 100mm;

[0046] Corresponding to the jet grouting pile 1, it is laid longitudinally along the length direction of the station. At the wall structure inside the jet grouting pile 1, the 3 pipe holes of the dewatering well are drilled obliquely to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com