Rice equipment and storage method thereof

A rice storage technology, applied in the direction of botany equipment and methods, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the broken rate of rice, damp waist, etc., to improve the effectiveness, promote temperature and humidity, and ensure Effects of Continuity and Fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

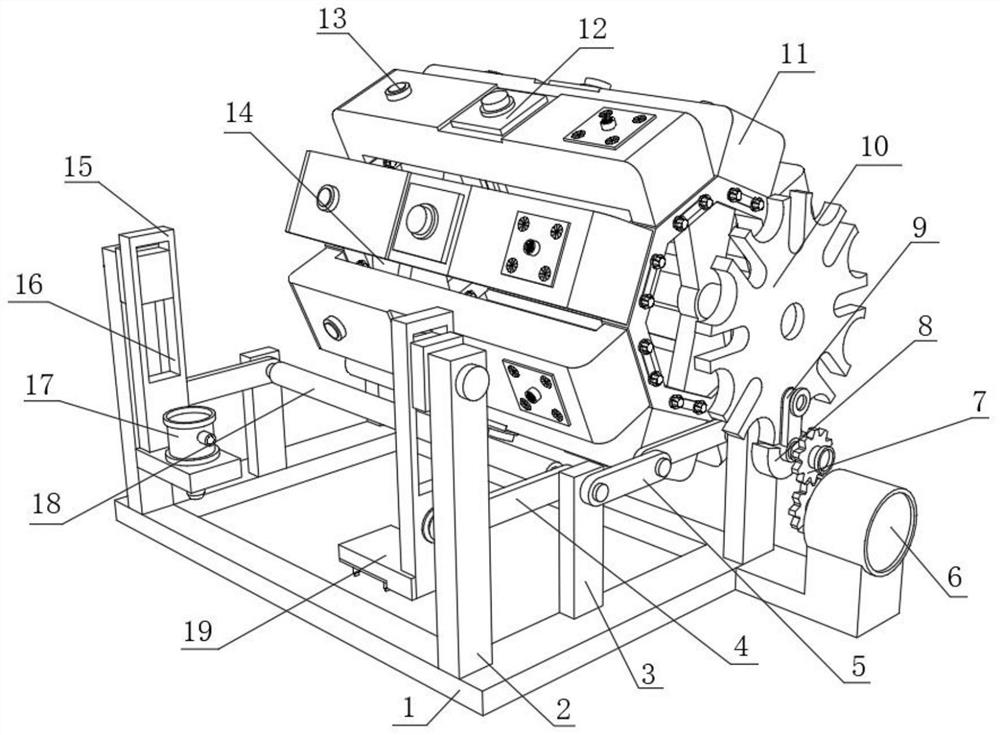

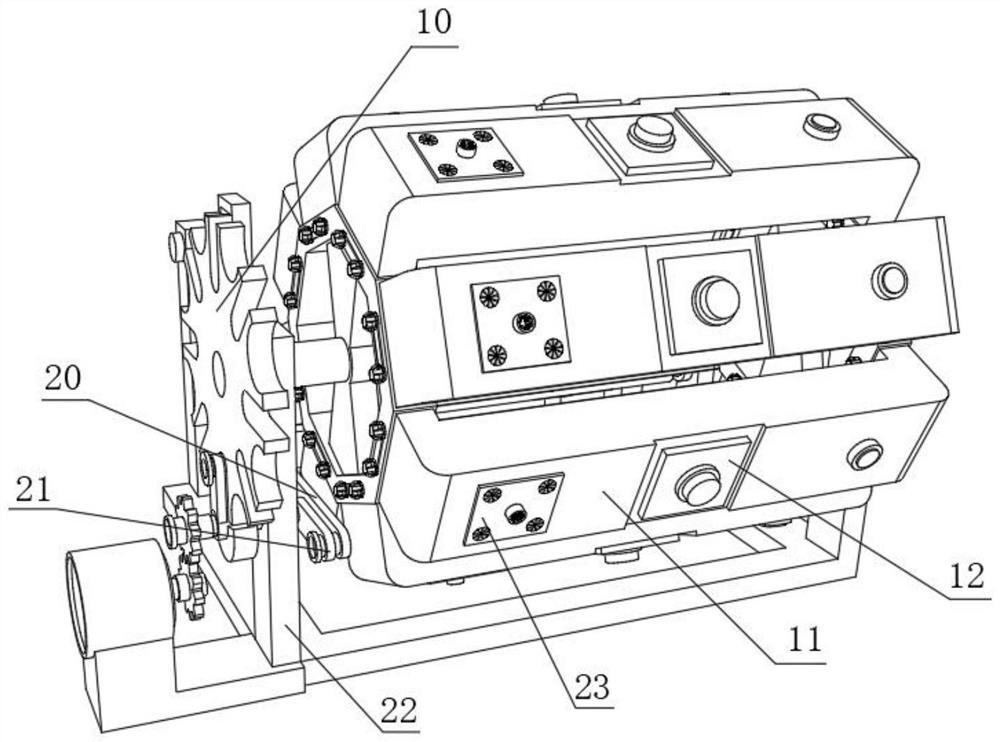

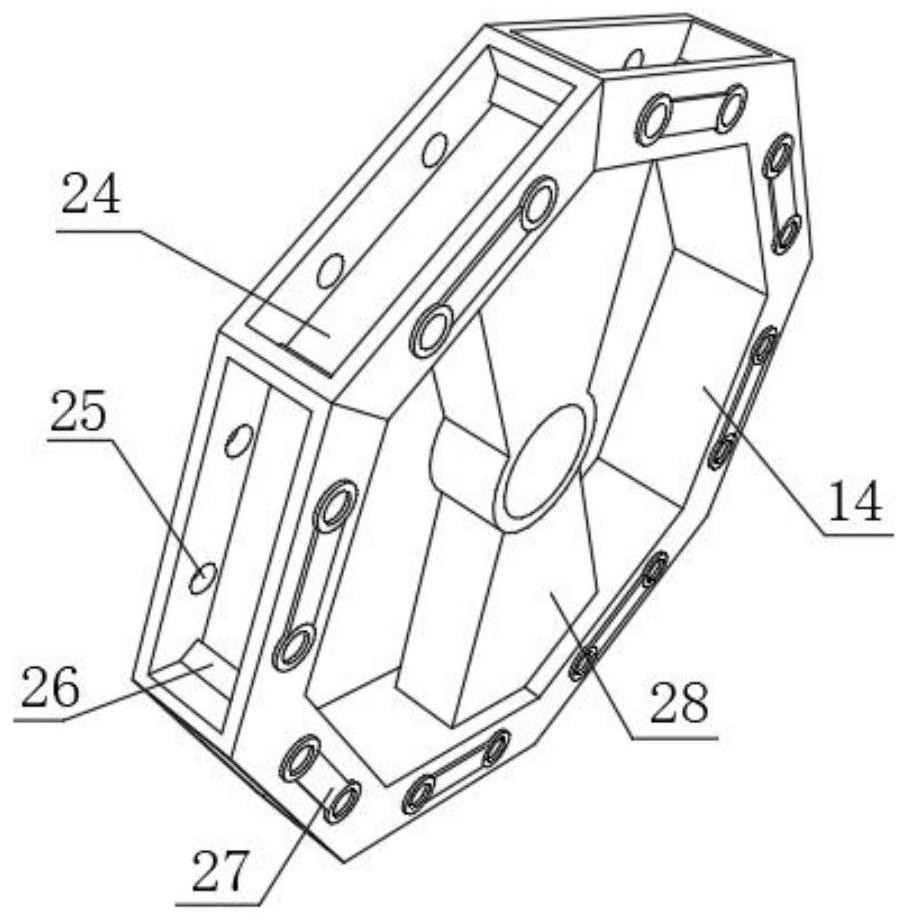

[0042] A kind of rice equipment and storage method thereof, such as Figure 1-6 As shown, it includes a base 1, and the two sides of the top of the base 1 are respectively fixed with a first support plate 2, a second support plate 3 and a third support plate 22 by bolts, and one set of the first support plate 2, the second support plate One side of the support plate 3 and the third support plate 22 is provided with an intermittent rotation mechanism, and the outer walls of the opposite sides of the two third support plates 22 are connected by a rotating shaft, and the two ends of the rotating shaft are respectively connected with an octagonal fixing frame through a fixing block 38 14, and the eight-sided outer wall of the octagonal fixed frame 14 is provided with snap-in slots 24, and the two inner ends of each snap-in slot 24 are provided with receiving pieces 26, and the two inner and outer walls of each snap-in slot 24 are provided with Two clamping holes 25, the octagonal ...

Embodiment 2

[0049] A kind of rice equipment and storage method thereof, such as Figure 5As shown, in order to effectively promote the drying and deworming effect of rice; this embodiment makes the following improvements on the basis of embodiment 1: the inner walls on both sides of the storage box 11 are respectively fixed with I-shaped partition plates distributed equidistantly by bolts 36, and the I-shaped partition plate 36 is provided with a storage chamber 37, the inner walls of both sides of the storage chamber 37 are provided with filter screens 35, and the outer walls of both sides of the I-shaped partition plate 36 are respectively bonded with PE film 34, and the filter screen 35 includes Impurity removal layer 351, water absorption layer 352 and bacteria removal layer 353. There are equidistantly distributed sterilization holes in the bacteria layer 353, and the top and bottom inner walls of each sterilization hole are provided with slow flow protrusions 3532 and fixed protrusi...

Embodiment 3

[0051] A rice equipment and storage method thereof, comprising the following steps:

[0052] S1: Prepare eight boxes for packing rice, install multiple cavity partitions inside them, and pack dry kelp into the partitions;

[0053] S2: Connect eight boxes for storing rice between two octagonal supports, and introduce rice into each box;

[0054] S3: Drive the eight rice storage boxes to perform intermittent circular motion through the intermittent rotation mechanism, and at the same time, the intermittent rotation mechanism also drives its output end to detect the temperature and humidity of each circular motion storage rice box;

[0055] S4: When the temperature and humidity in each box exceeds the set value, the air in the box is effectively pumped by starting the suction mechanism on the intermittent rotation mechanism;

[0056] S5: Finally, the rice can be regularly sampled and inspected through the feeding port on each box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com