Lateral stabilizer bar assembly, lateral stabilizer bar system and vehicle

A technology of stabilizer bar and stabilizer bar, applied in the direction of interconnection system, vehicle components, transportation and packaging, etc., can solve the problem that the torque of the stabilizer bar cannot be adjusted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

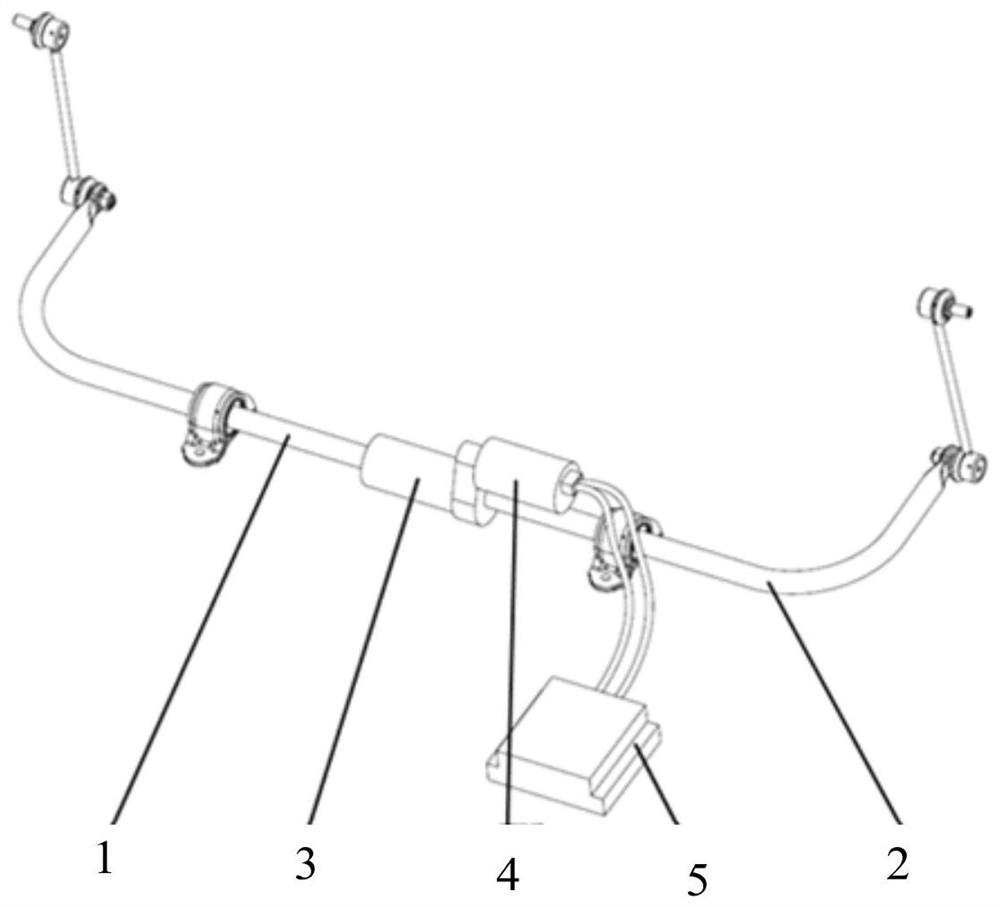

[0042] In order to solve the above technical problems, the present invention provides a stabilizer bar assembly, see figure 1 , including a first stabilizing bar 1, a second stabilizing bar 2, a clutch mechanism 3 and a driving mechanism 4. Specifically, the relative installation positions of the first stabilizing bar 1 and the second stabilizing bar 2 can be set according to actual needs. In this embodiment No further limitation is made; in this embodiment, the first stabilizing bar 1 is located on the left side of the second stabilizing bar 2 . In this embodiment, the whole of the first stabilizing rod 1 and the second stabilizing rod 2 is U-shaped.

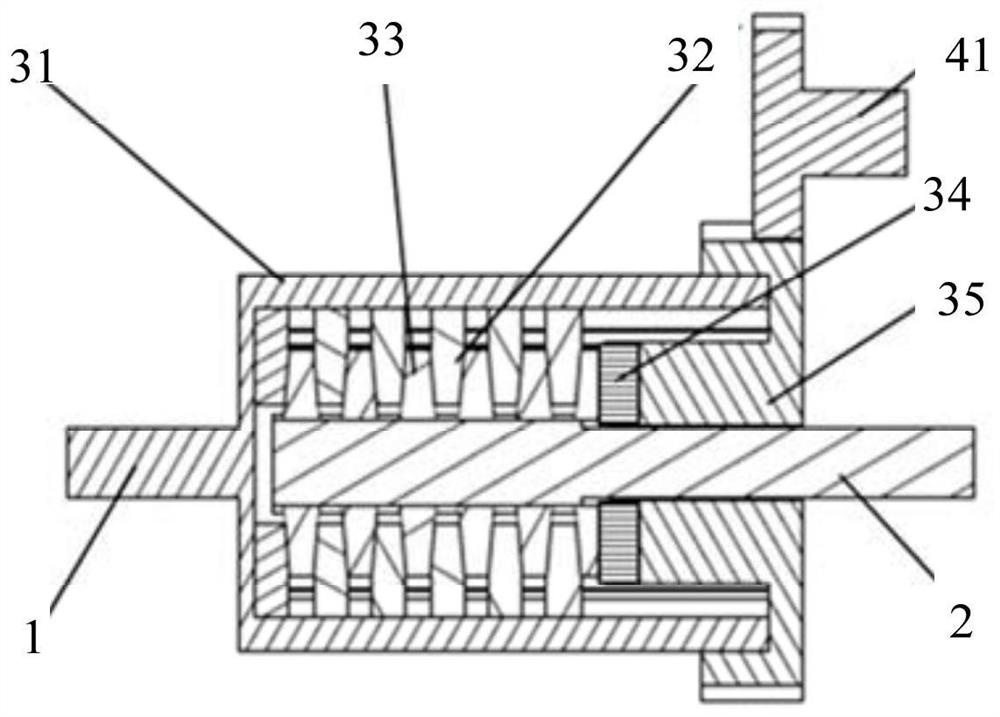

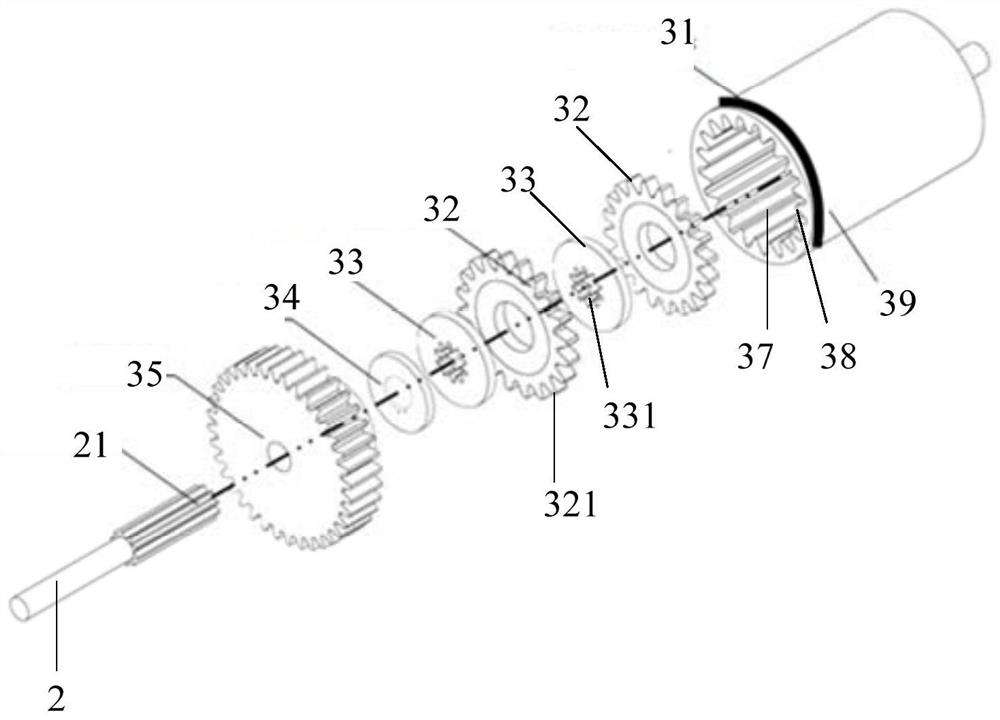

[0043] see Figure 2-3 , the clutch mechanism 3 includes a clutch housing 31 , a friction part and a top cover 35 .

[0044]A chamber 37 is formed inside the clutch housing 31 , and one end of the clutch housing 31 is an opening communicating with the chamber 37 , the friction portion includes a plurality of first friction me...

Embodiment 2

[0061] The invention also discloses a vehicle. The vehicle includes the stabilizer bar system in Embodiment 2. The stabilizer bar system in the vehicle in this embodiment can realize the output torque of the first stabilizer bar and the second stabilizer bar between 0 and Stepless variation between maximum values is possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com