Application method of tea withering device

A withering device and tea technology, which is applied in the field of tea withering devices, can solve the problems of inconvenient tea drying, moisture is not easy to dissipate, and affect the taste of tea, so as to avoid heat and mildew, improve the efficiency and effect of withering, and improve the operability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

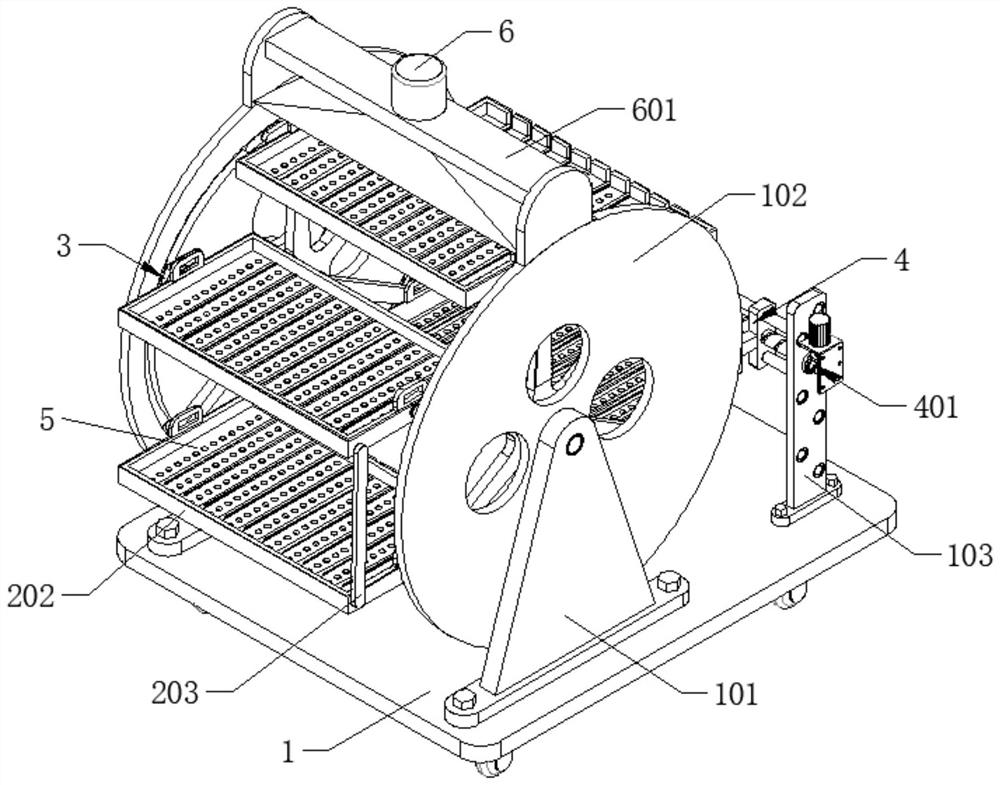

[0046] refer to Figure 1-8 , a tea withering device, including a base 1, the top wall of the base 1 is connected with a first support frame 101, and also includes:

[0047] The first driving mechanism 2 is installed on the outer wall of the first support frame 101, the output end of the first driving mechanism 2 is connected to the connecting frame 201, and the end of the connecting frame 201 is rotatably connected to the placement frame 202;

[0048] The airing frame 5 is placed inside the placing frame 202 and matched with it;

[0049] The guide plate 102 is arranged on the inner wall of the first support frame 101, and the guide plate 102 is connected to the connecting frame 201 in rotation. The inner wall of the guide plate 102 is dug with a chute 1021, and the chute 1021 is eccentrically arranged on the inner wall of the guide plate 102. A leveling compensation assembly 3 is arranged between the chute 1021 and the placement frame 202;

[0050] The second support frame ...

Embodiment 2

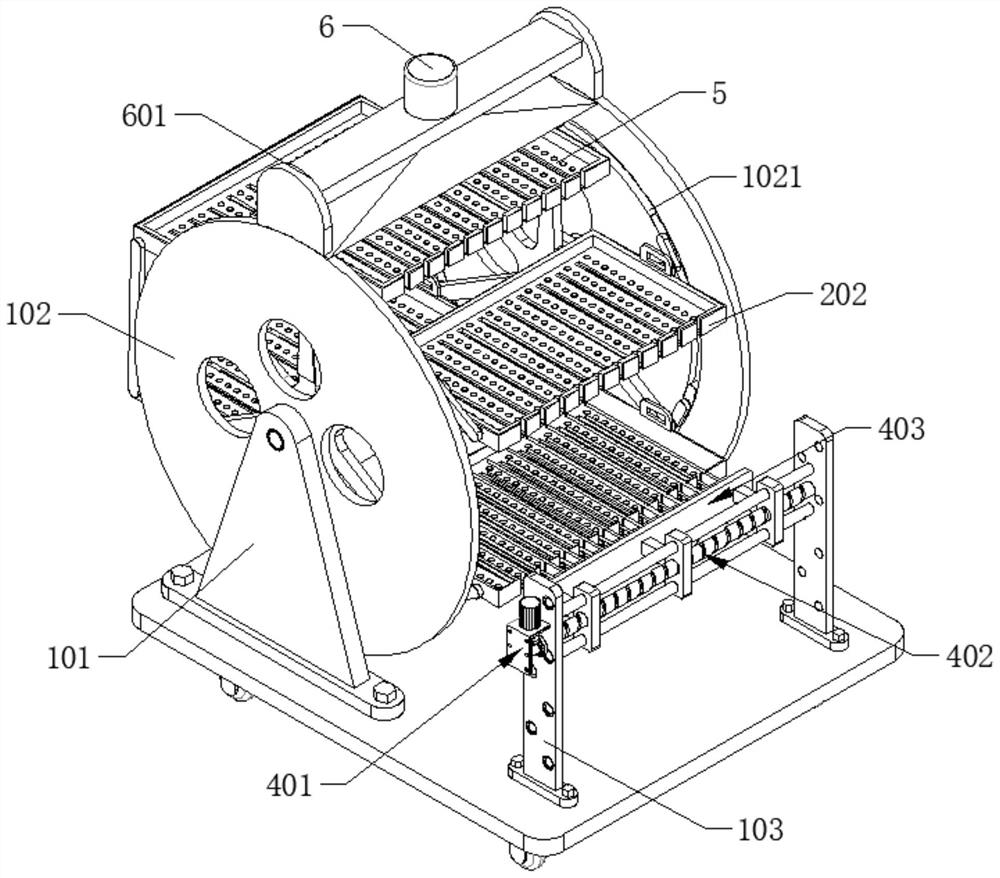

[0058] refer to Figure 1-2 , a tealeaves withering device, substantially the same as embodiment 1, further,

[0059] The second driving mechanism 401 includes a second driving motor 4011, a driving bevel gear 4012, a first driven bevel gear 4013 and a second driven bevel gear 4014, and the second driving motor 4011 is installed on the second support frame 103 through a mounting bracket. The driving bevel gear 4012 is connected to the output end of the second drive motor 4011, the first driven bevel gear 4013 and the second driven bevel gear 4014 are connected to the outer wall of the transmission mechanism 402 and are meshed with the driving bevel gear 4012, and the driving bevel gear 4012 Specifically a half gear.

[0060] The transmission mechanism 402 includes a ball screw 4021 and a guide rod 4022, the ball screw 4021 and the guide rod 4022 are connected inside the second support frame 103, and one end of the ball screw 4021 passes through the second support frame 103 an...

Embodiment 3

[0066] refer to Figure 1-2 , a tea withering device, basically the same as embodiment 1, further, a tea withering device, including a base 1, the top wall of the base 1 is connected with a first support frame 101, also includes:

[0067] The first driving mechanism 2 is installed on the outer wall of the first support frame 101, the output end of the first driving mechanism 2 is connected to the connecting frame 201, and the end of the connecting frame 201 is rotatably connected to the placement frame 202;

[0068] The airing frame 5 is placed inside the placing frame 202 and matched with it;

[0069] The guide plate 102 is arranged on the inner wall of the first support frame 101, and the guide plate 102 is connected to the connecting frame 201 in rotation. The inner wall of the guide plate 102 is dug with a chute 1021, and the chute 1021 is eccentrically arranged on the inner wall of the guide plate 102. A leveling compensation assembly 3 is arranged between the chute 1021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com