Valve assembly, heat exchange assembly, cabinet, cabinet cluster temperature control system and method and air conditioner room

A technology of valve components and cabinets, applied in the modification of standard racks/cabinets, valve devices, sliding valves, etc., can solve problems such as uneven air supply volume, downtime accidents, and ambient temperature exceeding the operating temperature range of equipment in the cabinet , to achieve the effect of increasing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] [Embodiment 1 related valve assembly]

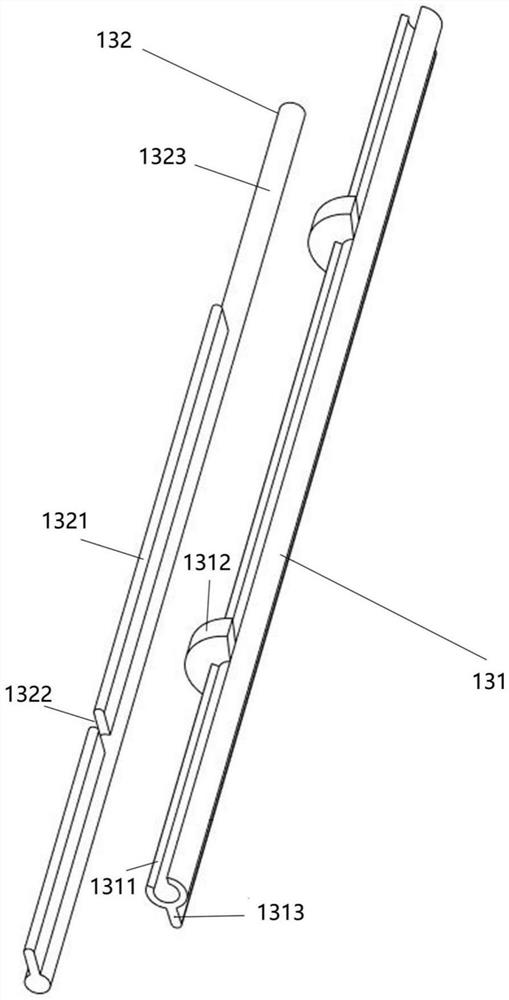

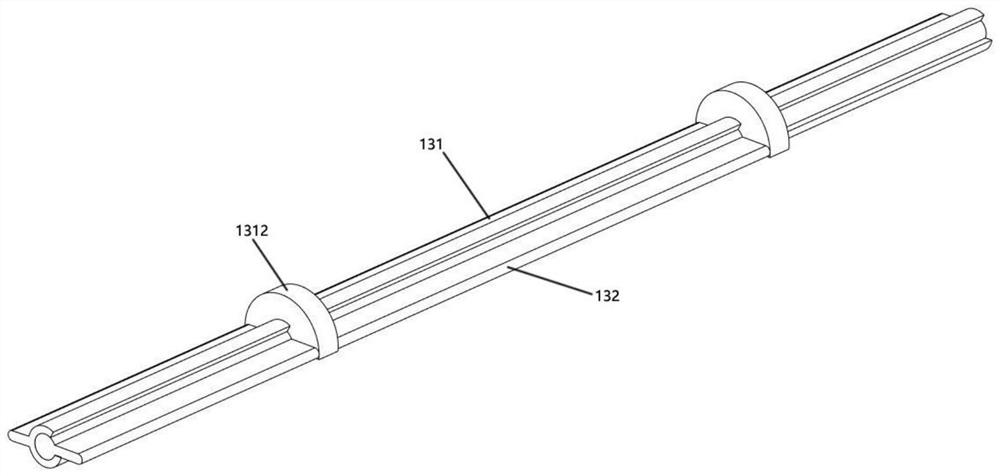

[0053] Such as Picture 1-1 , 1-2 , 2-1 to 2-3, a valve assembly provided in this embodiment is suitable for being arranged in a manifold, the main inventive concepts and corresponding structures are as follows:

[0054] Including stator valve plate 131, rotor valve plate 1323 and driving device;

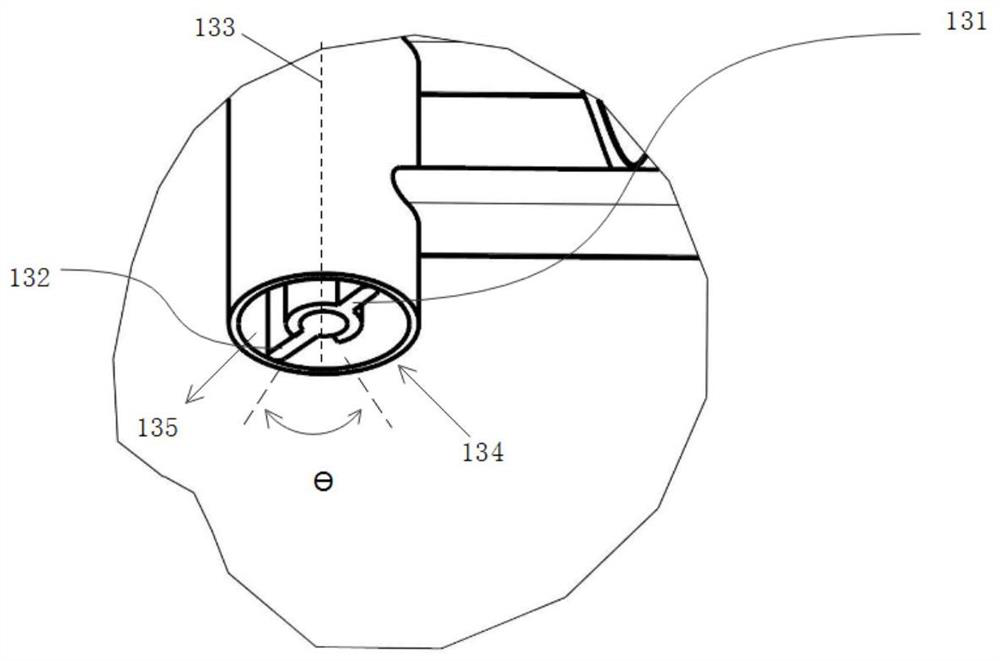

[0055] The length direction of the stator valve plate 131 is parallel to the length direction of the rotor valve plate 132, and the first end of the width direction of the stator valve plate 131 forms a hinged groove (referred to as a shaft sleeve 1311 in the following specific embodiments). The first end in the width direction of the rotor valve plate 132 forms a hinged shaft (referred to as the rotating shaft 1323 in the following specific embodiments), and the rotating shaft 1323 is embedded in the shaft sleeve 1311 and can rotate at a certain angle relative to the shaft sleeve 1311; The second end in the width direction of the sta...

Embodiment 2

[0066] [Embodiment 2 about the heat exchange assembly]

[0067] Such as Figure 2-1~2-3 As shown, a heat exchange assembly embodiment of the heat exchange assembly of the present invention includes a microchannel heat exchanger 120 and a valve assembly 130 as described above in any embodiment of the valve assembly of the present invention, and the microchannel heat exchanger (120) includes a microchannel Heat exchange tubes and manifolds, the valve assembly 130 is arranged in the manifold of the microchannel heat exchanger 120, the liquid inlet channel 134 of the valve assembly 130, the heat exchange tube of the microchannel heat exchanger 120 and the liquid outlet channel of the valve assembly 130 135 and the three are connected to form a circulation flow channel. In this embodiment, the valve assembly 130 and the microchannel heat exchanger 120 are combined into a heat exchange assembly, which can realize the regulation of liquid flow in the microchannel heat exchanger 120,...

Embodiment 3

[0068] [Cabinet related to Embodiment 3]

[0069] Such as image 3 Shown is an embodiment of the cabinet of the present invention, which is provided with the heat exchange assembly of any one of the above embodiments of the present invention.

[0070] Specifically, the cabinet includes a front door panel 110 and a cabinet body 20. The heat exchange components are laid on the inner side wall of the front door panel 110, and the length and width of the laying are equivalent to the size of the front door panel 110, so as to fully cover the equipment space in the cabinet. . The cabinet body 20 includes an outer frame 400 , a rear door panel 300 and a plug box 200 disposed on the outer frame 400 , and the front door panel 110 and the rear door panel 300 are hollow structures. The cold air enters the cabinet from the front door panel 110, and then exchanges heat with the micro-channel heat exchanger 120 to be further cooled. Outflow from the hollow hole of the rear door panel 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com