Aluminum-based circuit board etching equipment for LED lamp

A technology for LED lamps and etching equipment, which is applied to printed circuits, printed circuit manufacturing, and chemical/electrolytic methods to remove conductive materials, etc., can solve the problems of reducing the production speed of aluminum-based circuit boards, cumbersome operations, and increasing etching processing time. , to achieve the effect of shortening the etching treatment time, spraying uniformly, and improving the etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

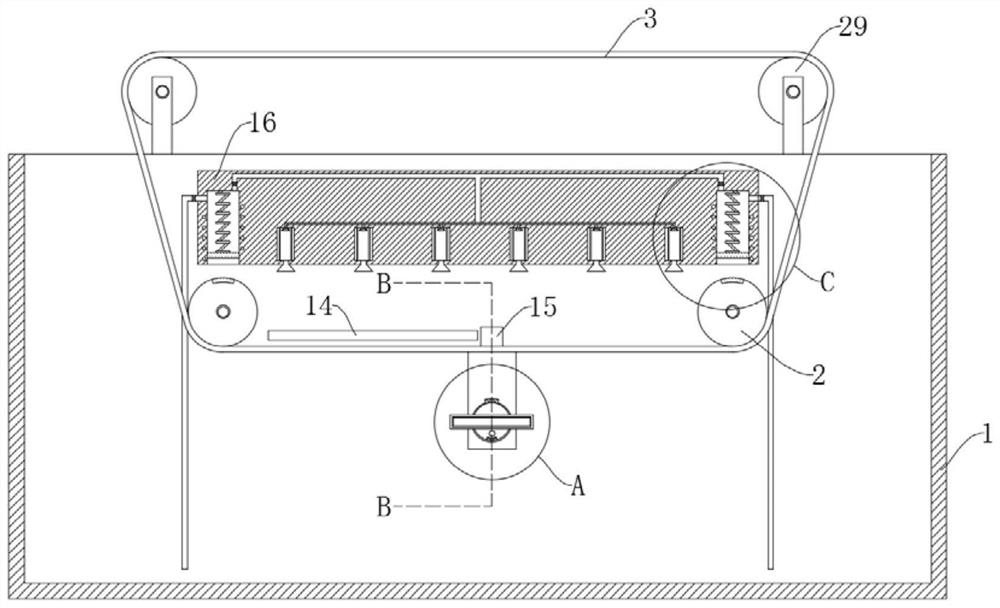

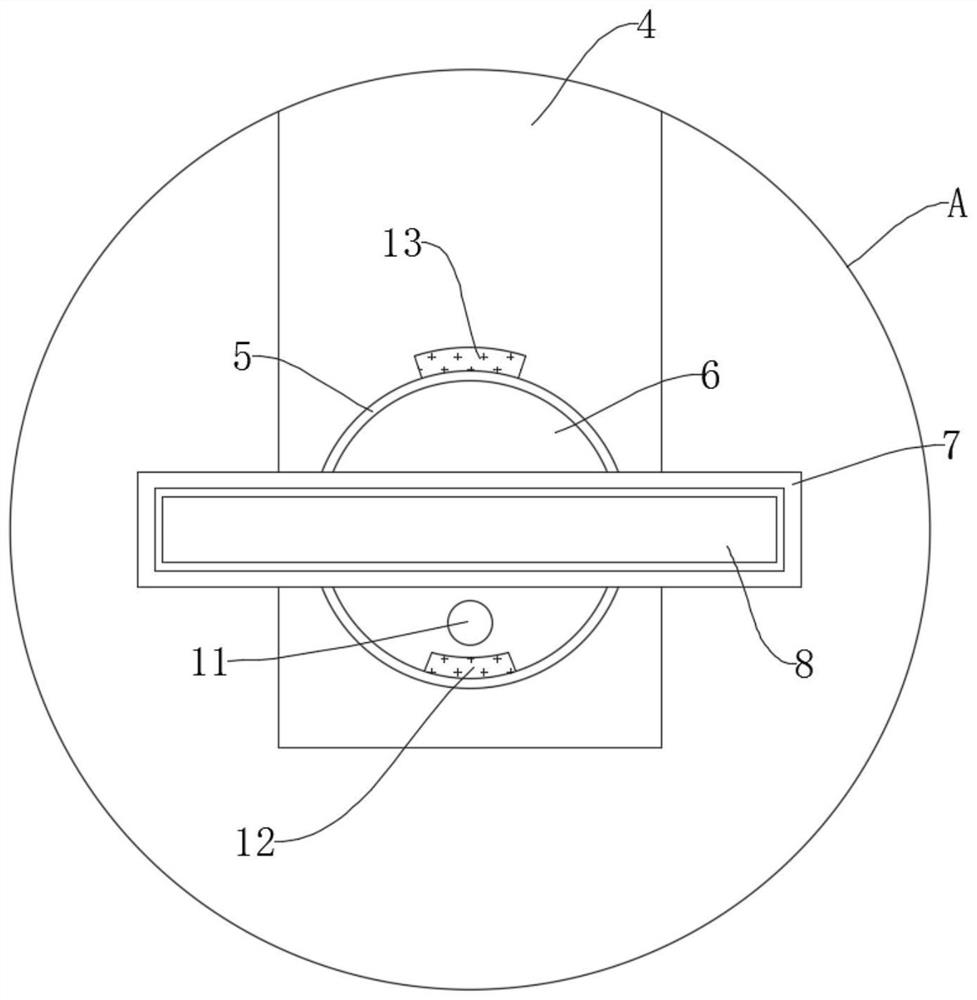

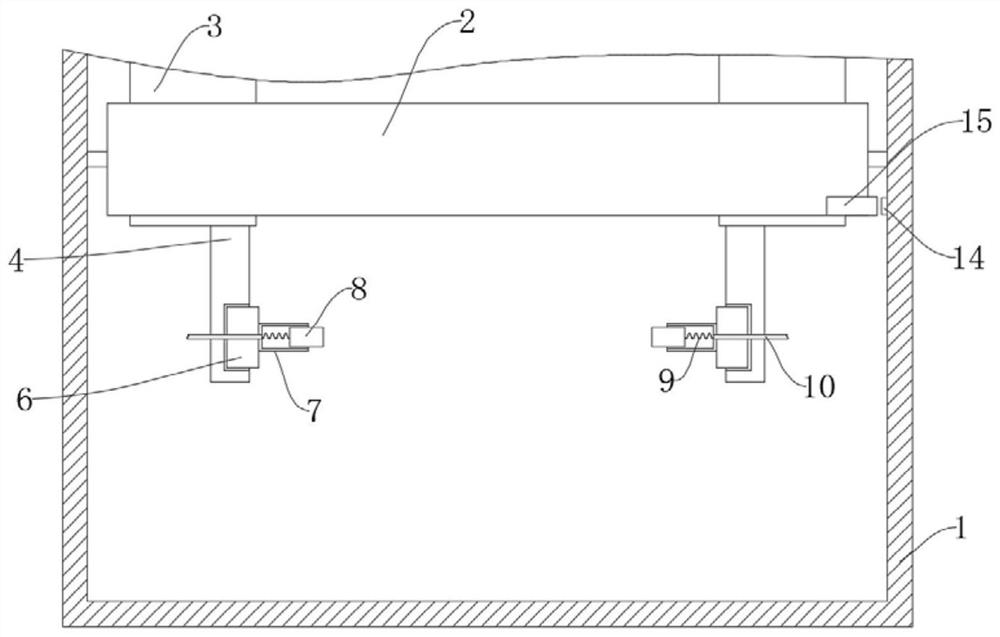

[0021] refer to Figure 1-4 , an aluminum-based circuit board etching device for LED lights, comprising a tank body 1, an etching solution is arranged in the tank body 1, two first driving rollers 2 are installed on the inner wall of the tank body 1, and two second driving rollers are installed on the upper end of the tank body 1 Two driving rollers 29, further, one of the second driving rollers 29 is connected with external driving equipment, which is prior art, two conveyor belts 3 are connected between the two first driving rollers 2 and the two second driving rollers 29 , the two conveyor belts 3 are provided with a clamping mechanism, the clamping mechanism includes a riser 4 fixedly connected to the conveyor belt 3, the side wall of the riser 4 away from the tank body 1 is provided with a circular groove 5, and the inner wall of the circular groove 5 Slidingly connected with a turntable 6, the side wall of the turntable 6 is fixedly connected with a sleeve plate 7, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com