Airplane complex wire harness laying method, device, equipment, storage medium and product

A wire harness and aircraft technology, applied in the field of aircraft system assembly, can solve problems such as low wiring harness laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

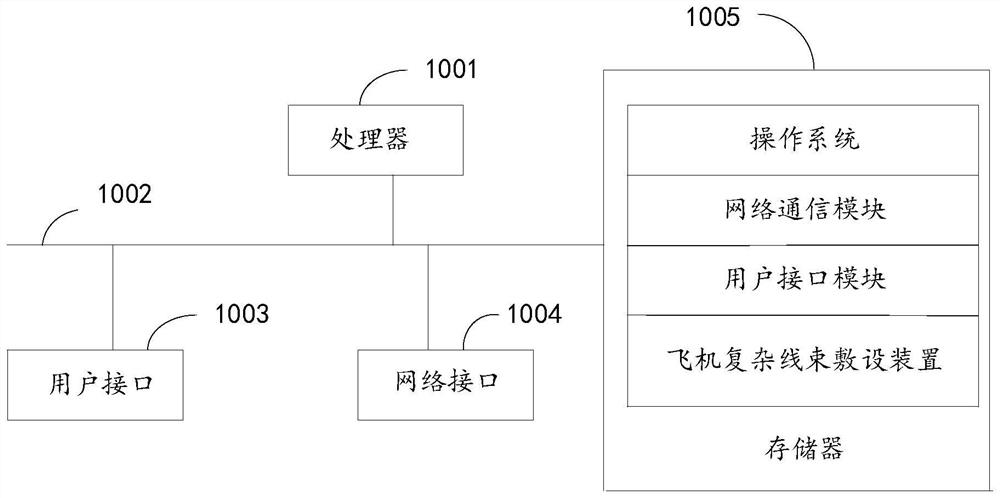

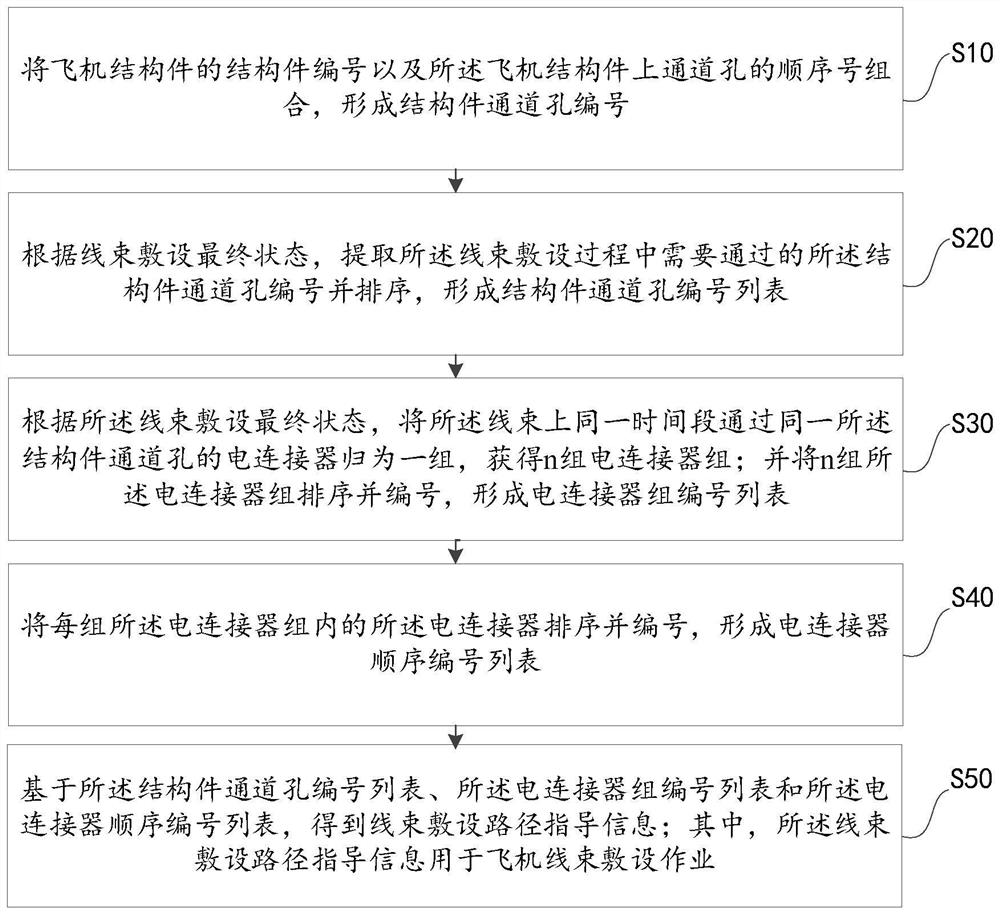

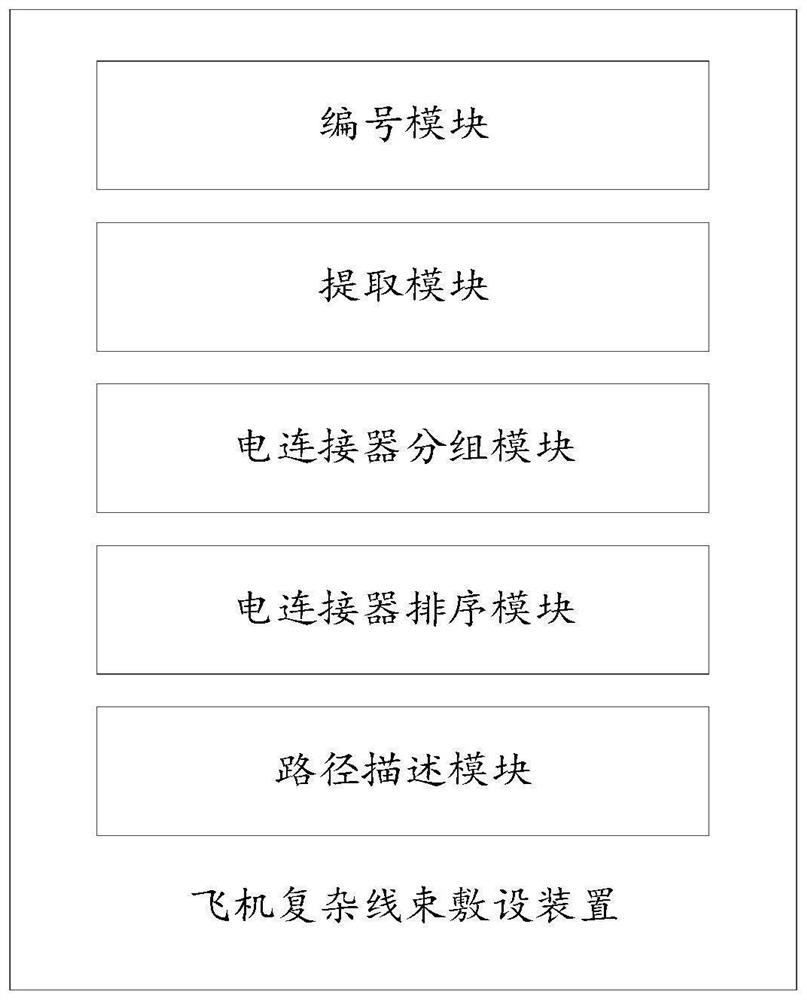

[0040] The main solution of the embodiment of the present application is: a proposed method, device, equipment, storage medium and product for laying complex wiring harnesses of an aircraft by combining the serial numbers of the structural parts of the aircraft structural parts and the sequence numbers of the passage holes on the aircraft structural parts , to form the channel hole number of the structural part; according to the final state of the wiring harness laying, extract and sort the channel hole numbers of the structural part that need to pass through the wiring harness laying process, and form a list of channel hole numbers of the structural part; according to the final state of the wiring harness laying, Group the electrical connectors on the wiring harness that pass through the same chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com