Method for determining acetohydroxamic acid in wheat flour and wheat flour treating agent

A flour treatment agent, acetohydroxamic acid technology, applied in the field of chemical analysis, to achieve the effect of high sensitivity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

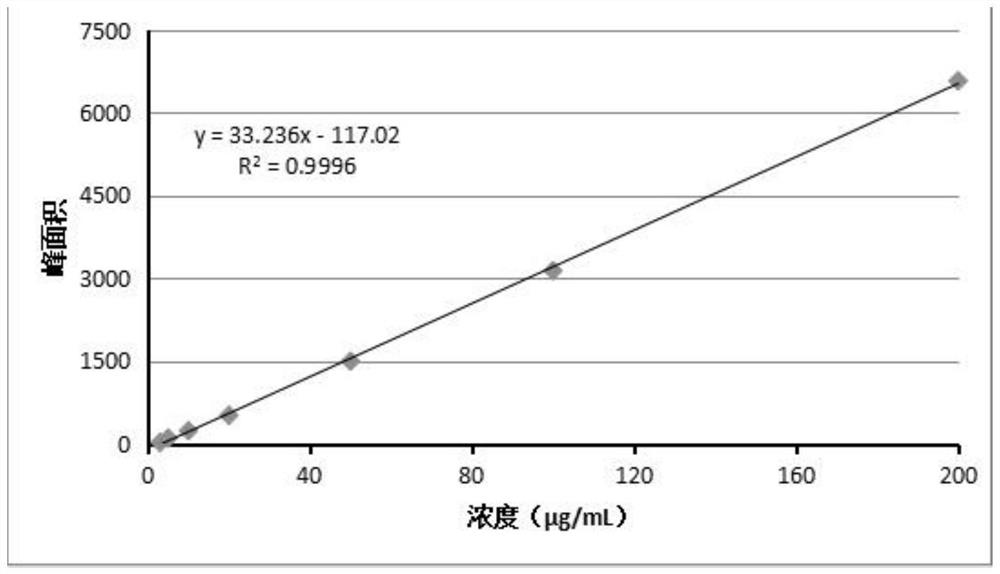

Examples

Embodiment 1

[0056] extract

[0057] Accurately weigh 1g (accurate to 0.01g) of the sample, place it in a 15mL stoppered centrifuge tube, add 0.4g (accurate to 0.01g) of polyethylene glycol and mix well. Accurately add 10 mL of absolute ethanol, vortex for 10 min, extract with ultrasound (power: 100 kHz) for 10 min, and centrifuge at 8000 r / min for 5 min at 4°C. The supernatant was used for later use.

[0058] purify

[0059] Pipette 5 mL of supernatant and transfer to activated C 18 In the solid-phase extraction column, discard the first 3mL of effluent, collect the effluent, pass through a 0.22μm organic filter membrane, discard 2-5 drops of the initial filtrate, and take the subsequent filtrate to be tested on the machine.

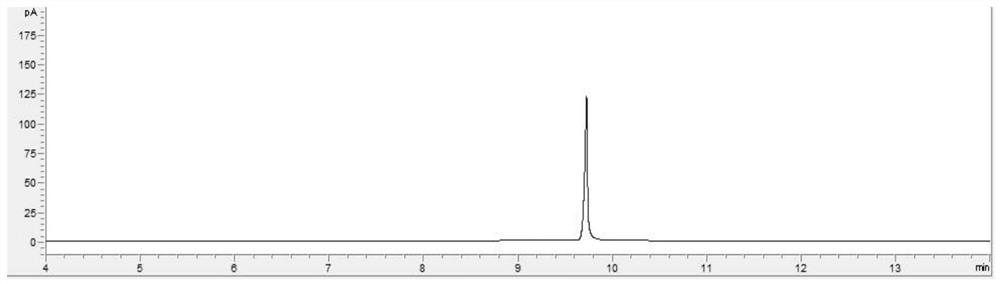

[0060] Gas Chromatography Reference Conditions

[0061] Chromatographic column: Agilent 19091N-1131 HP-INNOWAX (40~270℃), 30m×320μm×0.25μm, or equivalent;

[0062] Carrier gas: high-purity nitrogen, purity ≥ 99.9995%; column flow rate: 2.5mL / min.

[0063] Inlet ...

Embodiment 2~13

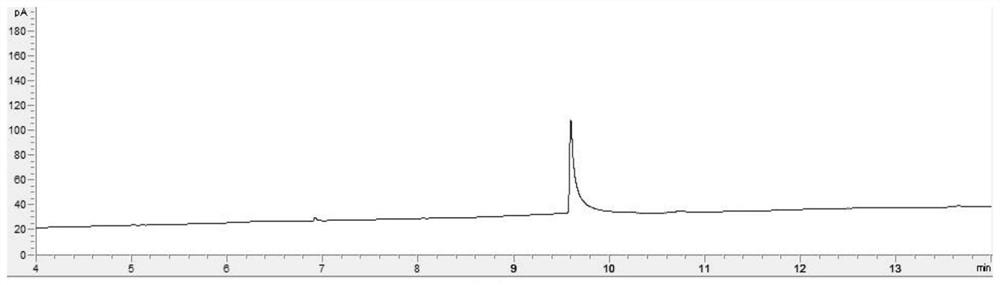

[0107] Sample testing

[0108] Select 6 batches of representative samples of wheat flour and flour treatment agent, a total of 12 batches of samples, and test according to the method specified in this standard. It is found that the residual amount of acetohydroxamic acid in the two batches of flour treatment agent samples is 38.46 ( see Figure 4 ) and 37.25mg / kg, and the residues of acetohydroxamic acid in the remaining samples were not detected.

[0109] Experimental effect

[0110] precision

[0111] The absolute difference between two independent determination results obtained under repeatability conditions shall not exceed 10% of the arithmetic mean.

[0112] Weigh 1g of blank matrix sample, add acetohydroxamic acid standard (n=6) at different levels, the addition level is 50mg / kg and 100mg / kg, process according to the proposed sample pretreatment method, test on the machine, investigate The precision of the method. The results are shown in Tables 5 and 6. The relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com