Detection equipment for electric power high-voltage equipment leakage and application thereof

A technology of high-voltage equipment and detection equipment, which is applied in the field of safety detection, can solve problems such as leak detection, inapplicable mixed gas detection, and lower detection results, and achieve the effects of improving accuracy, enhancing environmental detection adaptability, and improving cross-sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

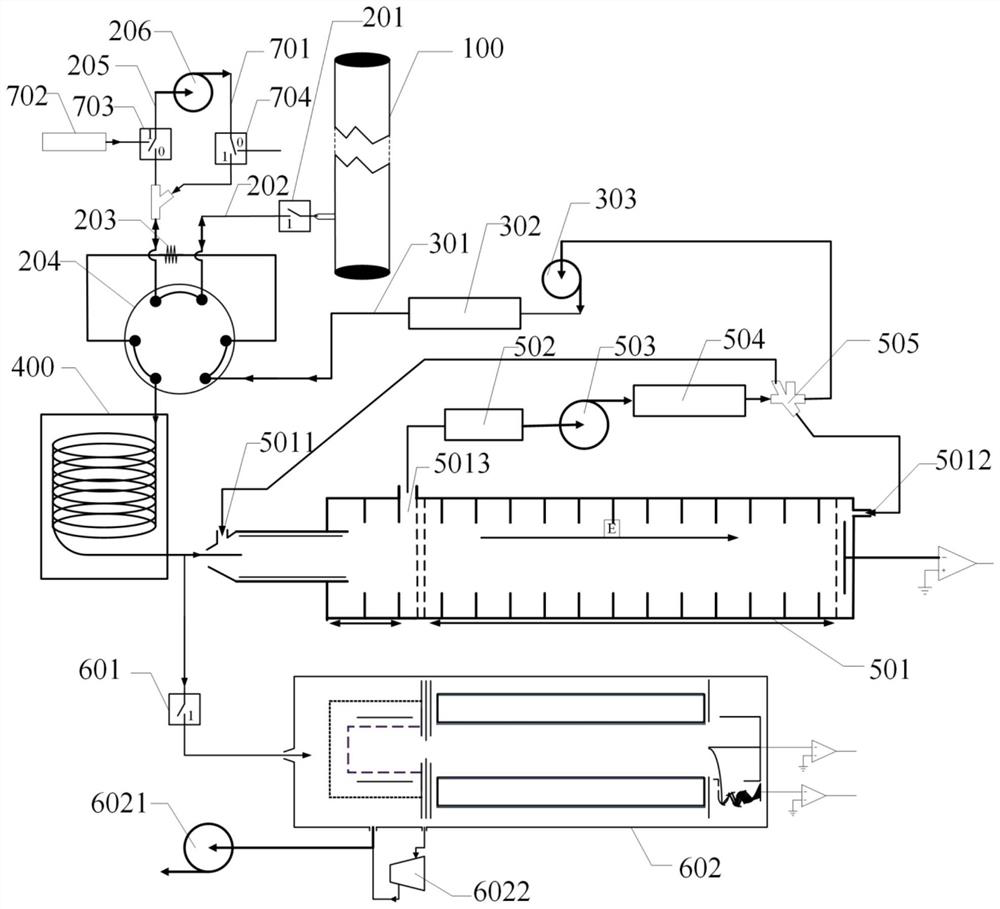

[0073] See Figure 1 ~ 3 As shown, the present embodiment provides a detection device for a power high pressure device leak, including: a sampling unit, carrier gas unit, GC column 400, and detection unit; wherein the sampling unit includes a first sampling tube sequentially connected. Road 200, quantitative ring 203, control valve 204, the second sampling line 205, and the pump 206, the input end of the first sampled line 200 is connected to the interface of the high voltage device pipe 100, and both ends of the quantitative ring 203 are both a control valve. 204 connection, one end of the control valve 204 is connected to the output of the first sample line 200, and the other end is connected to the pump 206 through the second sampling line 205, the extra gas pump 206 collects the sample in the high pressure equipment pipe 100 to the quantitative ring. In 203, the samples include sf 6 And / or sf 6 Decomposing product; Connection, for pre-separation of the mixed sample; the detec...

Embodiment 2

[0106] In this embodiment, a detecting apparatus for the leakage of a power high pressure device is provided, which is the same as that in the detection apparatus in Example 1, and details are not described herein again.

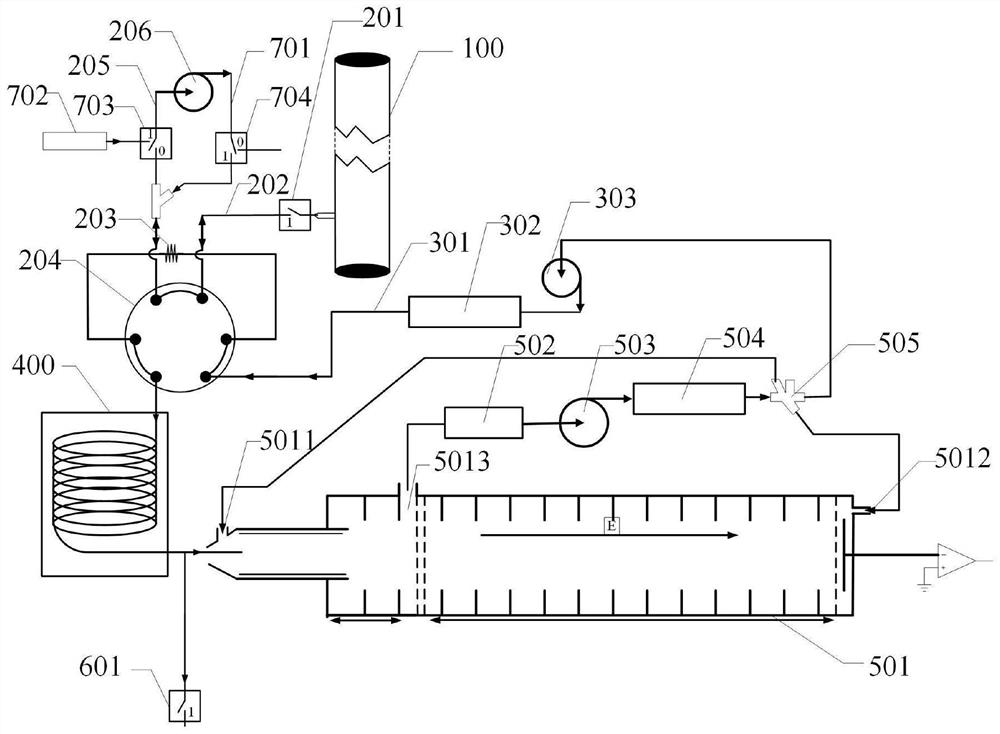

[0107] In this embodiment, the SF leakage of the electric high pressure device is allowed to use the IMS detection system separately using the IMS detection system. 6 SF 6 When the inspection or detection of the decomposing product is detected by the detection apparatus in the present embodiment, the specifically detecting method is subjected to SF in Example 1. 6Compared with the detection method of high voltage equipment or online detection, the evolution solenoid valve 601 is always in a closed state, and the pre-separated sample is all entered into the IMS detection system. Steps S1, S2, S3 are identical, This is no longer described again.

Embodiment 3

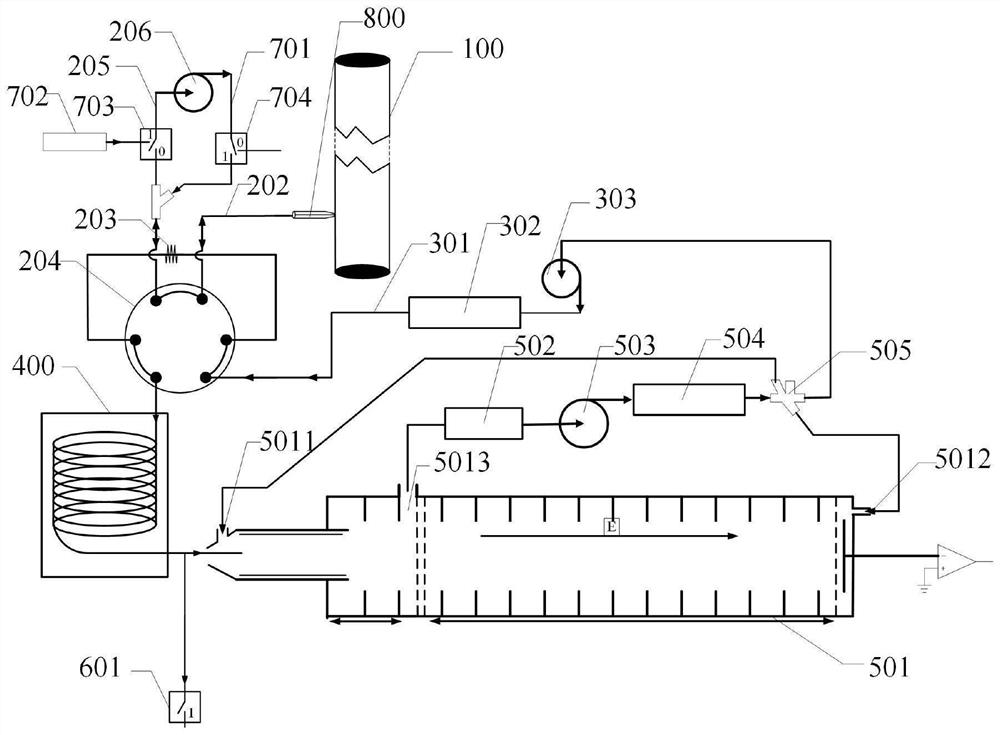

[0109] This embodiment provides a detection apparatus for the leakage of the power high pressure device, which is different from the detection device in Example 1, and the sampling solenoid valve 201 connected to the input of the first sampling line 200 Replacement is the same as the sampling structure, and the other structures are the same as in Example 1, and details are not described herein again.

[0110] As an example, the sampling structure is a sampling cone 801 or a sampled head 802; see Figure 4 , Figure 5 The sampling cone 801 is tapered, including the first port 8011 and the second port 8012, and the first port 8011 and the second port 8012 are connected to the sample cavity, and the first port 8011 is attached to the high pressure equipment pipe 100. The second port 8012 is connected to the first sampling line 200, and the inner diameter of the first port 8011 is larger than the inner diameter of the second port 8012; the sample head 802 is a pen-shaped sample head 802...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com