Semi-combined pressure ring sensor and design method thereof

A pressure ring and sensor technology, applied in the field of semi-combined pressure ring sensor and its design, can solve the problems of difficult to achieve compression volume, lack of installation space, and great impact on accuracy, so as to reduce the cost of defective products and mass production efficiency High and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

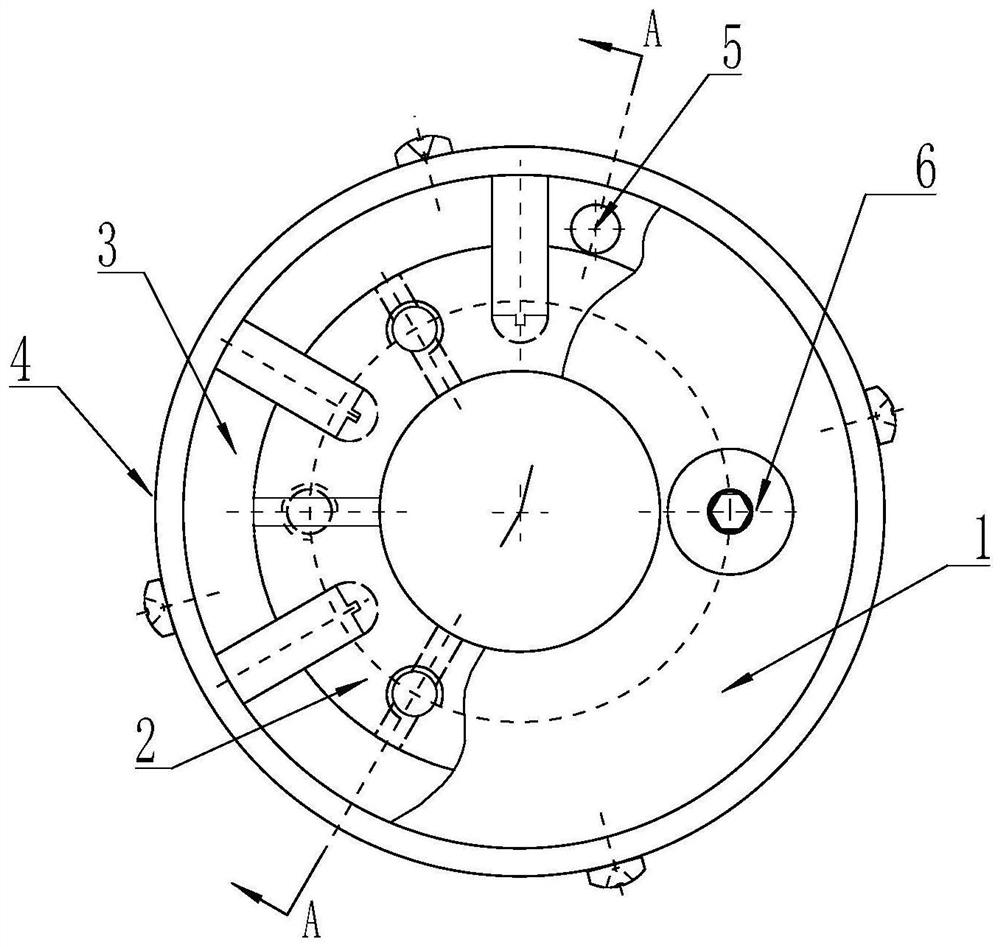

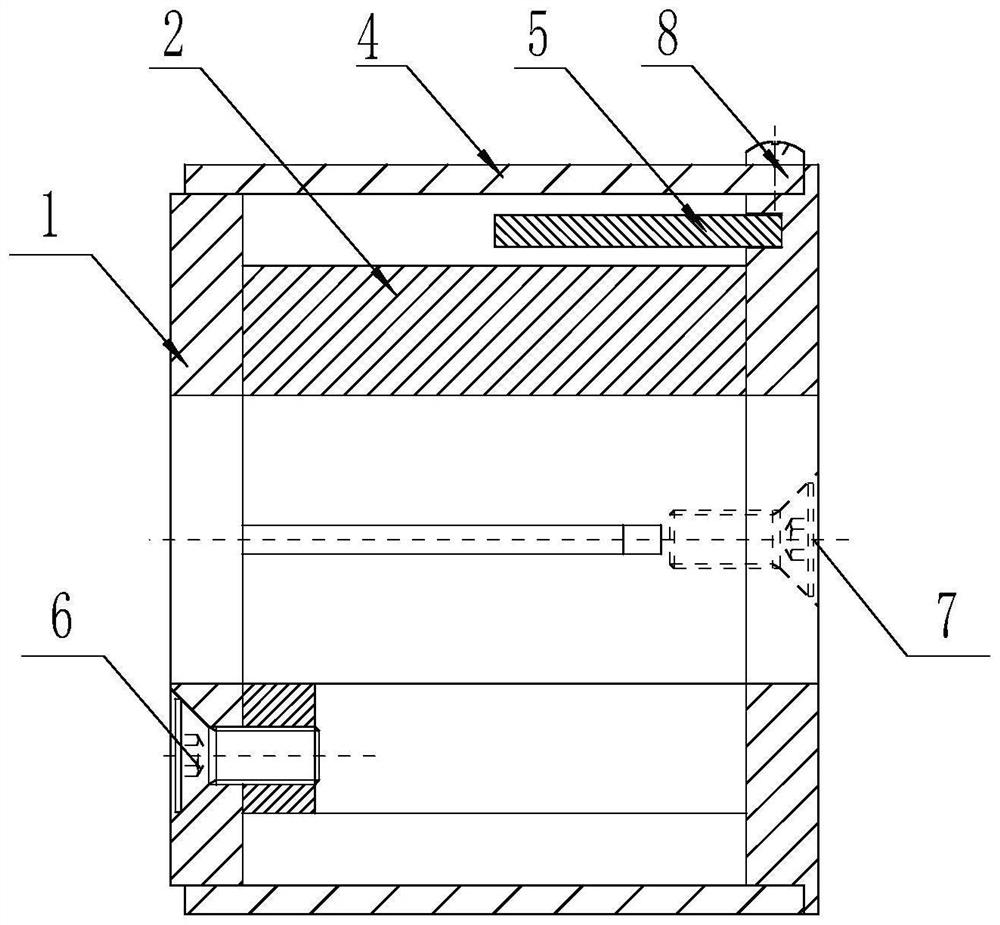

[0083] Figure 1-Figure 2 Disclosed in is a semi-combined pressure ring sensor, including an upper pressure plate 1, a pressure bearing ring 2, a lower pressure plate 3, an outer sleeve 4, and a temperature compensation column 5;

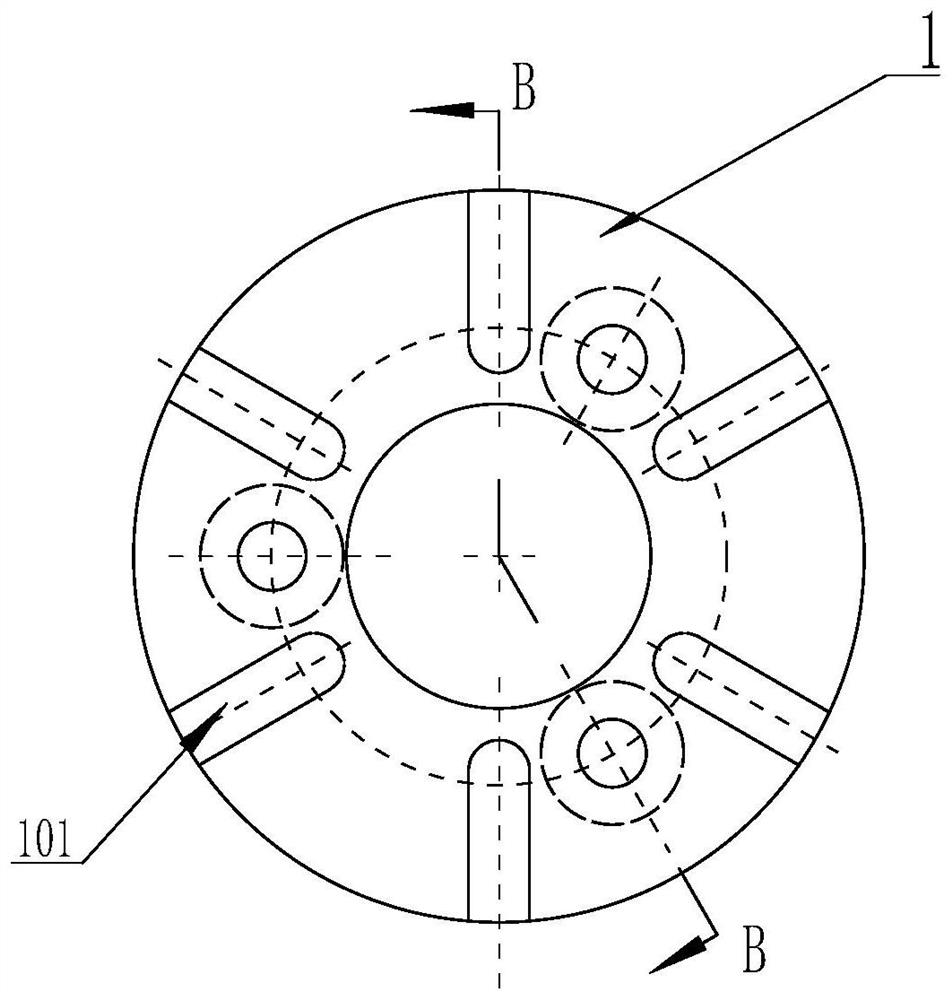

[0084] The upper pressure plate 1 is provided with three installation holes I102; the pressure bearing ring 2 is located in the outer sleeve 4, and the two ends of the pressure bearing ring 2 are respectively provided with three installation holes II204; the lower pressure plate 3 is provided with installation hole III 303, installation hole IV 304 and threaded hole 302; one end of the outer sleeve 4 is provided with installation hole V401. The number, position and size of the installation hole I102 of the upper platen 1 and the installation hole II204 at one end of the pressure ring 2 match, and the screw I6 connects the upper platen 1 and the pressure ring 2 tightly through the installation hole I102 and the installation hole II204 together; the ...

Embodiment 2

[0094] A semi-combined pressure ring sensor, the structure of which is basically the same as that of Embodiment 1, including an upper pressure plate 1, a pressure bearing ring 2, a lower pressure plate 3, an outer sleeve 4, and a temperature compensation column 5; the only difference is:

[0095] The distribution positions of the n=6 dividing seams 201 on the pressure bearing ring 2 are different, such as Figure 13-Figure 14 As shown, the distribution was ipsilateral.

Embodiment 3

[0097] A design method of a semi-combined pressure ring sensor, which is the design method of the semi-combined pressure ring sensor described in Embodiment 1 or Embodiment 2, which is to calculate the minimum pressure-bearing area and minimum outer diameter of the pressure-bearing ring respectively , the minimum height, and locate the measuring point groove Ⅰ; then design the supporting upper platen, lower platen, outer sleeve and temperature compensation column respectively, and obtain the minimum outer diameter and minimum height of the semi-combined pressure ring sensor, and complete the half-combination The design of pressure ring sensor.

[0098] The concrete steps of this method include:

[0099] S1. Calculation of the minimum pressure-bearing area of the pressure-bearing ring:

[0100] Assume that the force of the actual use environment is F, and the number of measuring points required by the design is n, that is, the number of pressure-bearing areas is n. In order to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com