Stator core assembly, stator assembly, motor device and method thereof

A stator core and component technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems affecting the performance and application of the motor, the accuracy is not ideal, and the production cost is high, so as to save processes and materials, eliminate harmonic components, The effect of excellent vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate understanding of the present invention, various exemplary embodiments will be described below with reference to the associated drawings. It should be understood by those skilled in the art that the embodiments herein are only for the purpose of illustrating the present invention, rather than limiting the present invention by any means.

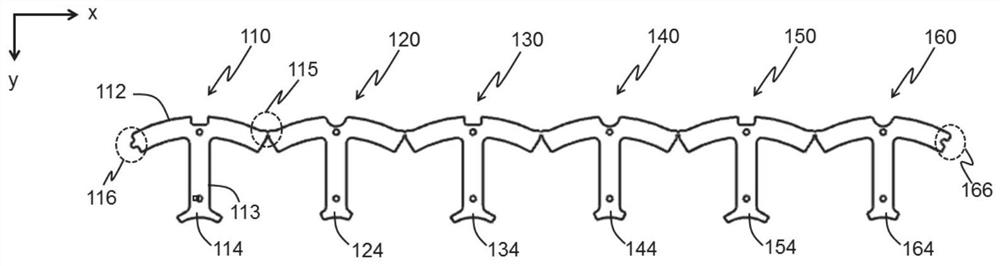

[0031] According to one aspect of the present invention, figure 1 A schematic structural diagram of a stator core assembly according to some embodiments of the present invention is shown. The illustrated stator core assembly, for example, may be used to form at least a portion of a stator assembly of an electric machine. The motor may be one or more suitable motor types, such as an inner rotor motor, a brushless motor, or the like.

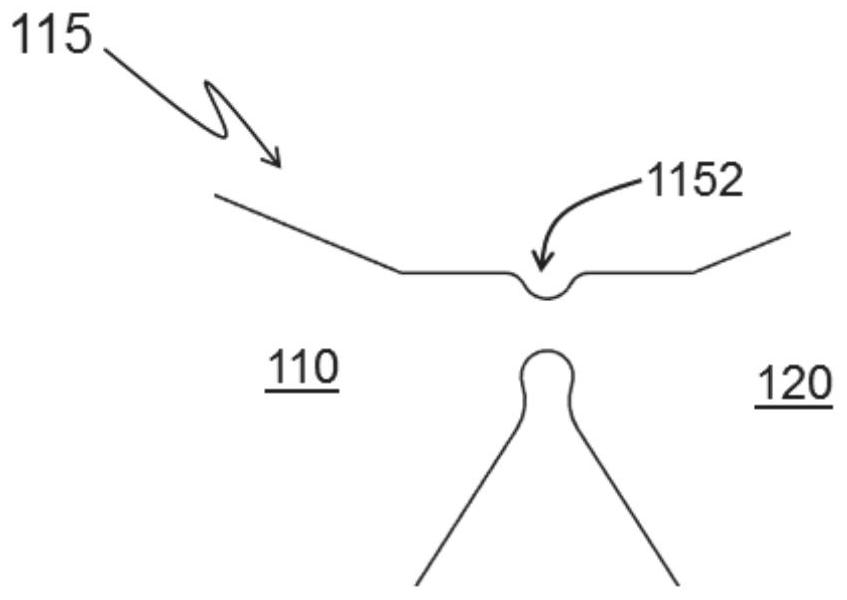

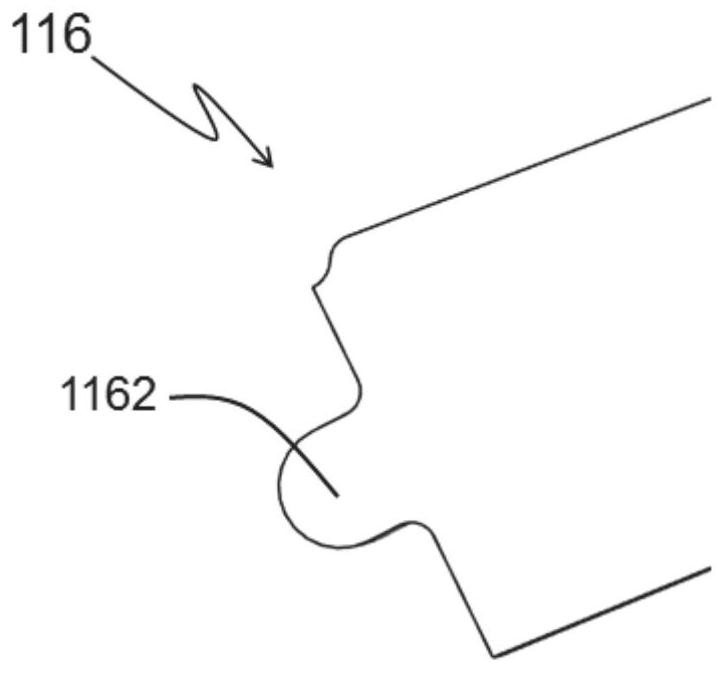

[0032] like figure 1 As shown, the stator core assembly includes a plurality of core units 110 , 120 , 130 , 140 , 150 , 160 . Each core unit includes a yoke and a tooth. For the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com