Tunneling roadway rapid supporting equipment and working method thereof

A roadway and fast technology, applied in mining equipment, earthwork drilling, mine roof support, etc., to reduce labor intensity, increase stability, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

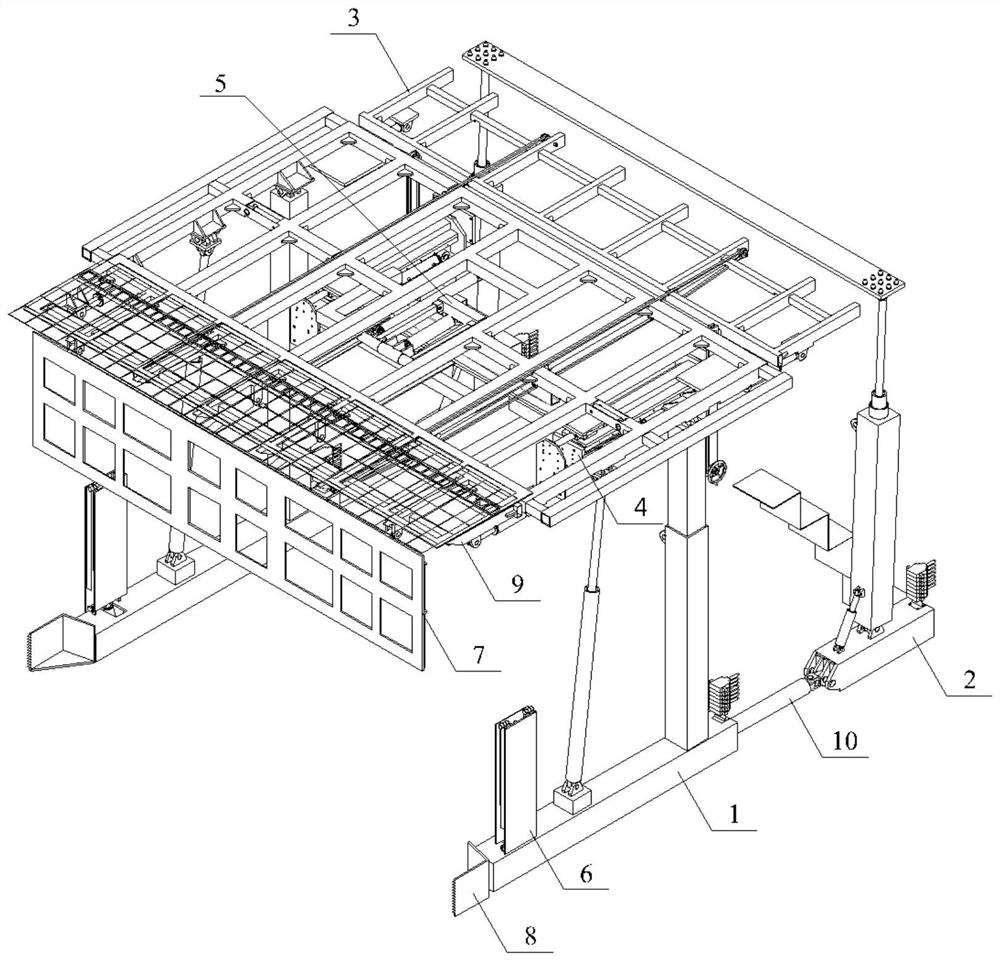

[0065] see Figure 1-7 , the present invention provides a technical solution: a rapid support equipment for tunneling roadway, including:

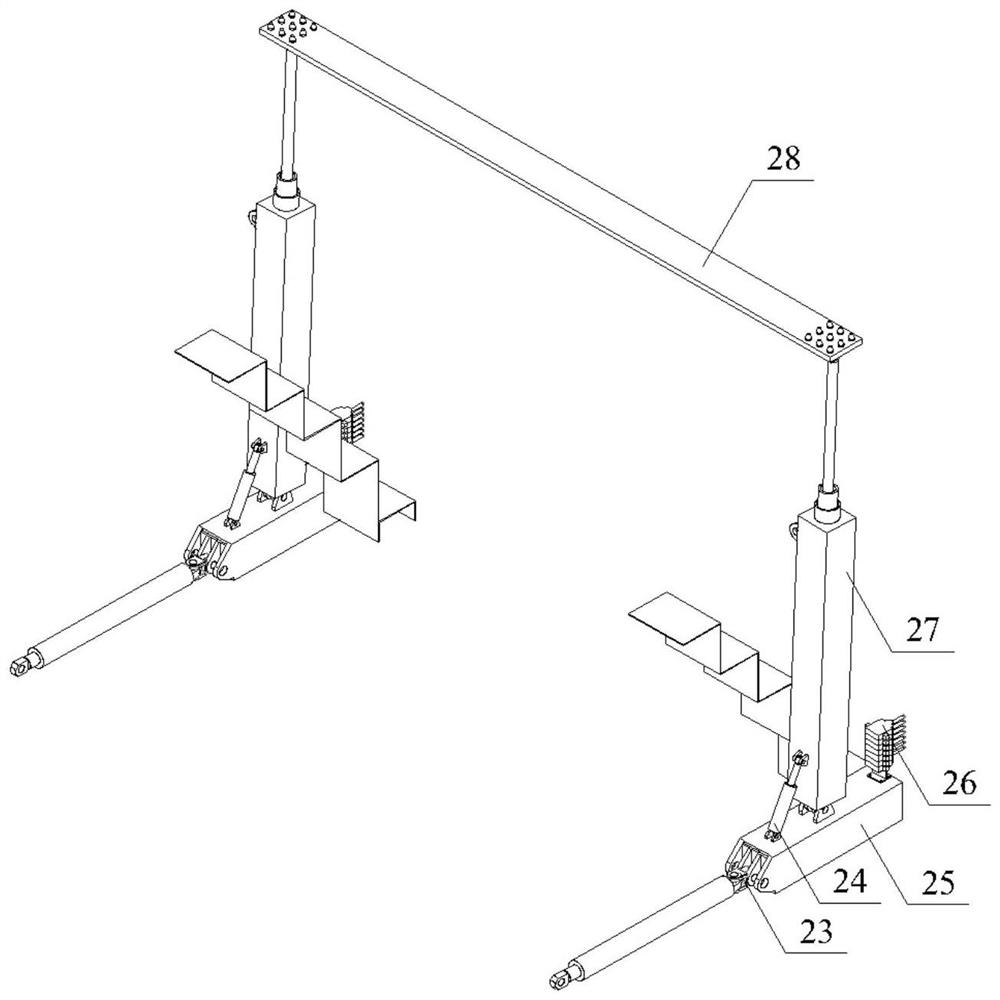

[0066] The first support frame unit 1 includes: a first support frame base 11, a first support frame guide support 12 and a first support frame top beam 14, one end of the first support frame guide support 12 and the first support frame base 11 is fixedly connected, and the other end is hinged to the top beam 14 of the first support frame;

[0067] The second support frame unit 2 is connected to the first support frame base 11 through a connection mechanism, and the first support frame unit 1 and the second support frame unit 2 can slide relatively. In this implementation, the connection mechanism adopts Bottom push-pull oil cylinder 10, in other embodiments, also can adopt other devices as required;

[0068] The operating mechanism 26 and the power mechanism are used to control the operation of the rapid support equipment for the excava...

Embodiment 2

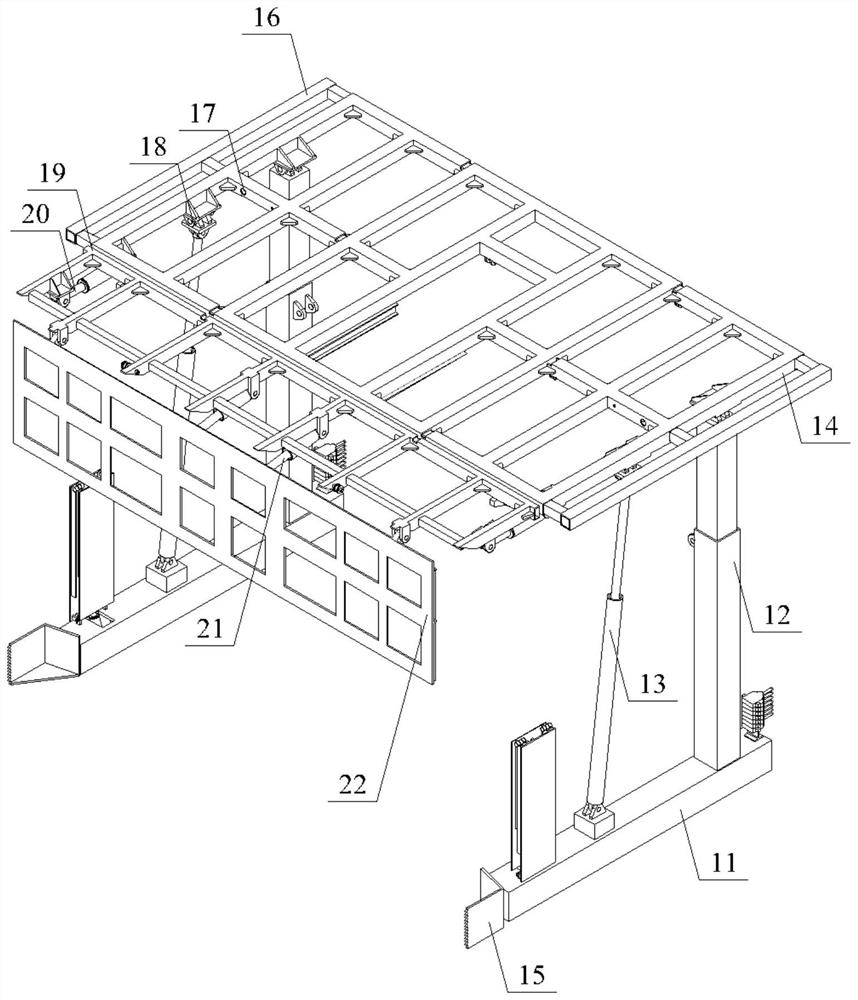

[0080] A rapid support device for tunneling in this embodiment is further improved on the basis of Embodiment 1. The multi-degree-of-freedom drilling rig moving mechanism 5 includes:

[0081] The horizontal chute 38 is arranged along the axial direction of the roadway, and is fixed below the top beam 14 of the first support frame;

[0082] A horizontal slider 40 is arranged in the horizontal chute 38 and is slidably connected with the horizontal chute 38;

[0083] The beam 42 is arranged below the horizontal chute 38 and connected with the horizontal slider 40 through the connecting frame 41;

[0084] The transverse chute 39 is opened on the beam 42, and the rock bolt unit 4 is slidably connected in the transverse chute 39, so that the rock bolt unit 4 has a transverse degree of freedom.

Embodiment 3

[0086] The rapid support equipment for tunneling roadway in this embodiment is further improved on the basis of Embodiment 1, and the first support frame unit 1 also includes:

[0087] The first support frame is inclined to support 13, one end is hinged to the first support frame base 11, and the other end is hinged to the first support frame top beam 14. In this implementation, the first support frame is inclined to support 13 through the first support frame The crosshead 18 is hinged on the top beam 14 of the first support frame, and in other embodiments, other structures can also be adopted as required;

[0088] The anchoring operation platform 6 is arranged on the base 11 of the first support frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com