Method for hoisting platform layer for transportation junction and steel beams below platform layer

A technology for transportation hubs and hoisting methods, applied to public buildings, processing of building materials, building types, etc., can solve problems such as difficult hoisting work and heavy weight of transverse steel beam components, so as to improve hoisting efficiency and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

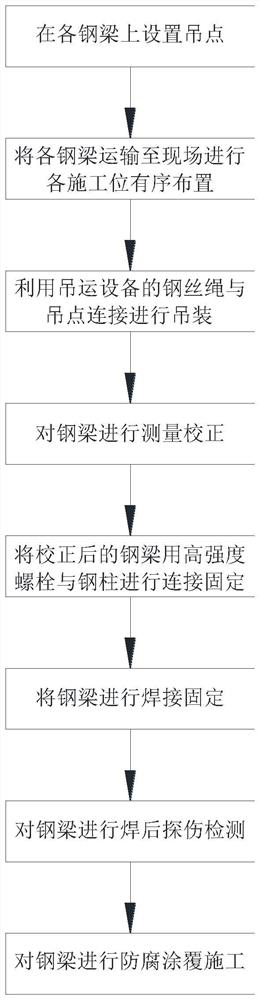

[0025] figure 1 and figure 2 An embodiment of the method for hoisting the platform layer and the following steel girders of the present invention for the traffic hub position is shown, including the following steps:

[0026] S1: Set hanging points on each steel beam;

[0027] S2: Transport the steel beams to the site for orderly arrangement of the construction positions;

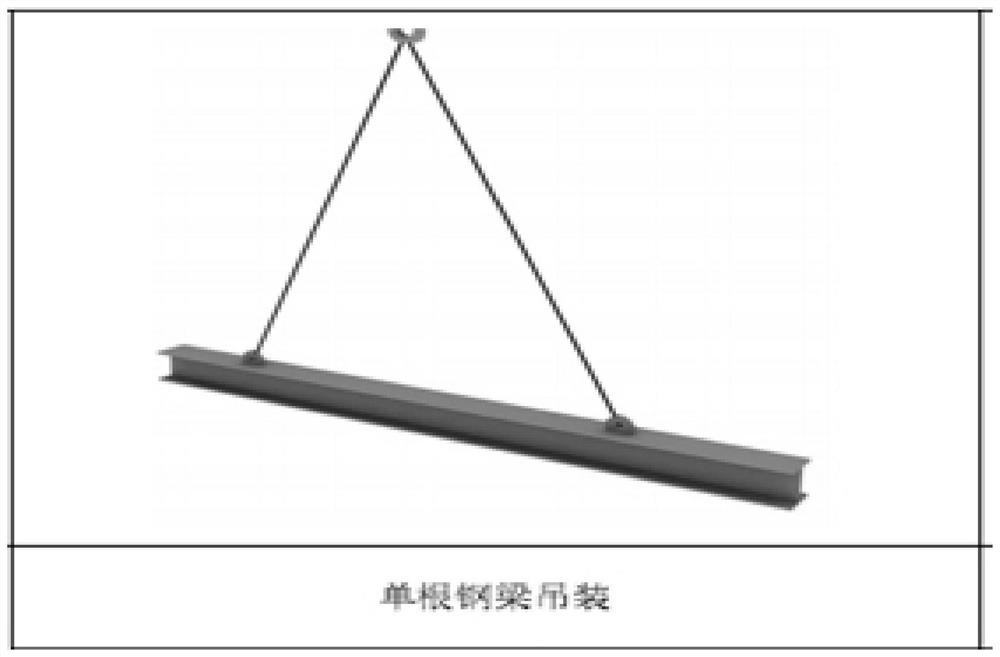

[0028] S3: Use the wire rope of the lifting equipment to connect with the lifting point for hoisting;

[0029] S4: Measure and correct the steel beam;

[0030] S5: Connect and fix the corrected steel beam to the steel column with high-strength bolts;

[0031] S6: welding and fixing the steel beam;

[0032] S7: Perform post-weld flaw detection on steel beams;

[0033] S8: Carry out anti-corrosion coating construction on steel beams.

[0034] With this method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com