Coke oven gas cracking and coke dry quenching integrated process and device

A coke oven gas and purification device technology, applied in coke ovens, chemical industry, coke cooling, etc., can solve the problems of low heat value of coke oven gas, high impurity content, and a large amount of natural hot gas resources provided by the ironmaking industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

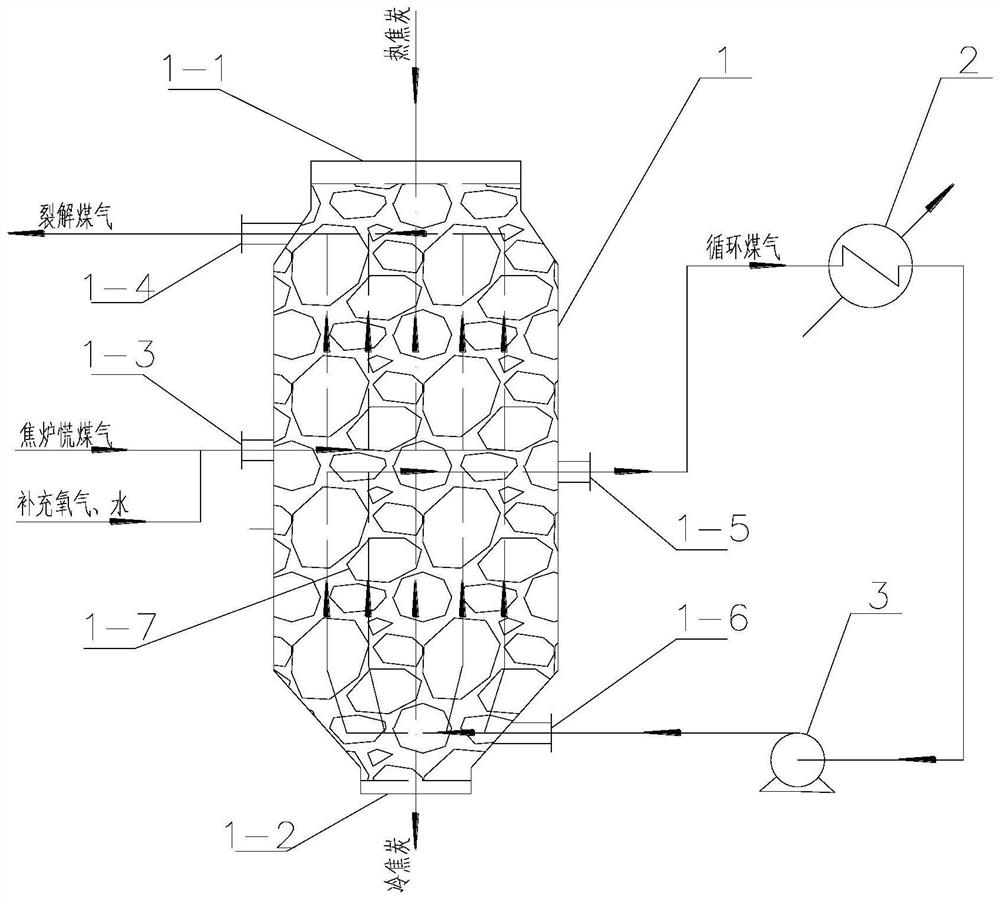

[0022] like figure 1 As shown, an integrated process of coke oven gas cracking and coke CDQ:

[0023] 1) The ~750°C high-temperature raw coal gas from the coke oven enters the middle part of the cracking CDQ furnace 1, and the high-temperature raw gas coming in from the middle part of the cracking CDQ furnace 1 flows upwards and downwards from the hot high-temperature coke in the middle part of the cracking CDQ furnace 1-7 Heat exchange and heat up to ~1050°C for high-temperature cracking, and the gas after high-temperature cracking is sent out from the upper part of cracking CDQ furnace 1;

[0024] 2) Coal gas at ~750°C is extracted from the middle part of the cracking CDQ furnace 1 as circulating cooling gas, which is recovered by the waste heat boiler 2 and cooled to 160°C, then pressurized by the circulating fan 2 and sent into the furnace from the lower part of the cracking CDQ furnace 1, from bottom to top Gradually cool the cokes 1-7 in the lower part of the cracking C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com