Production process of medical latex gloves

A production process and technology of latex gloves, applied in the medical field, can solve the problems of easy pollution, small friction, inconvenience for medical staff, etc., and achieve the effects of good stability, enhanced friction coefficient, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

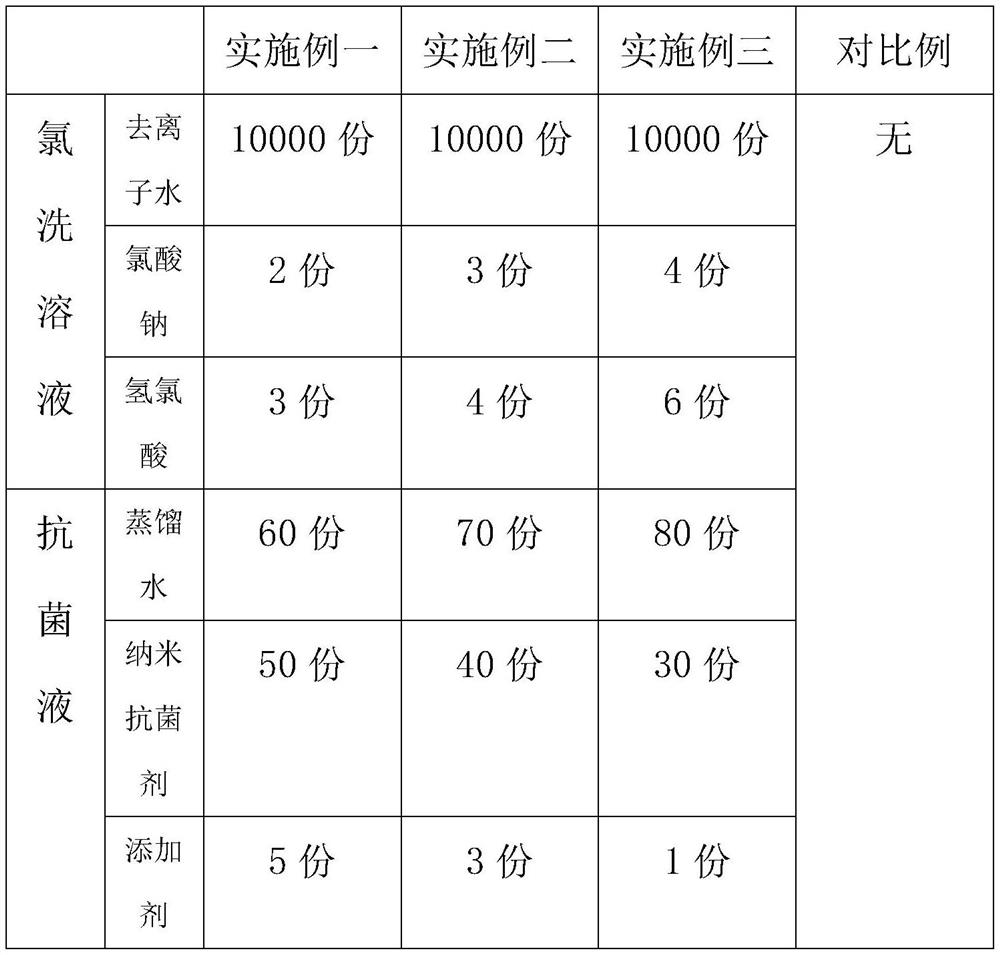

[0020] The present invention will be further explained below in conjunction with specific embodiments.

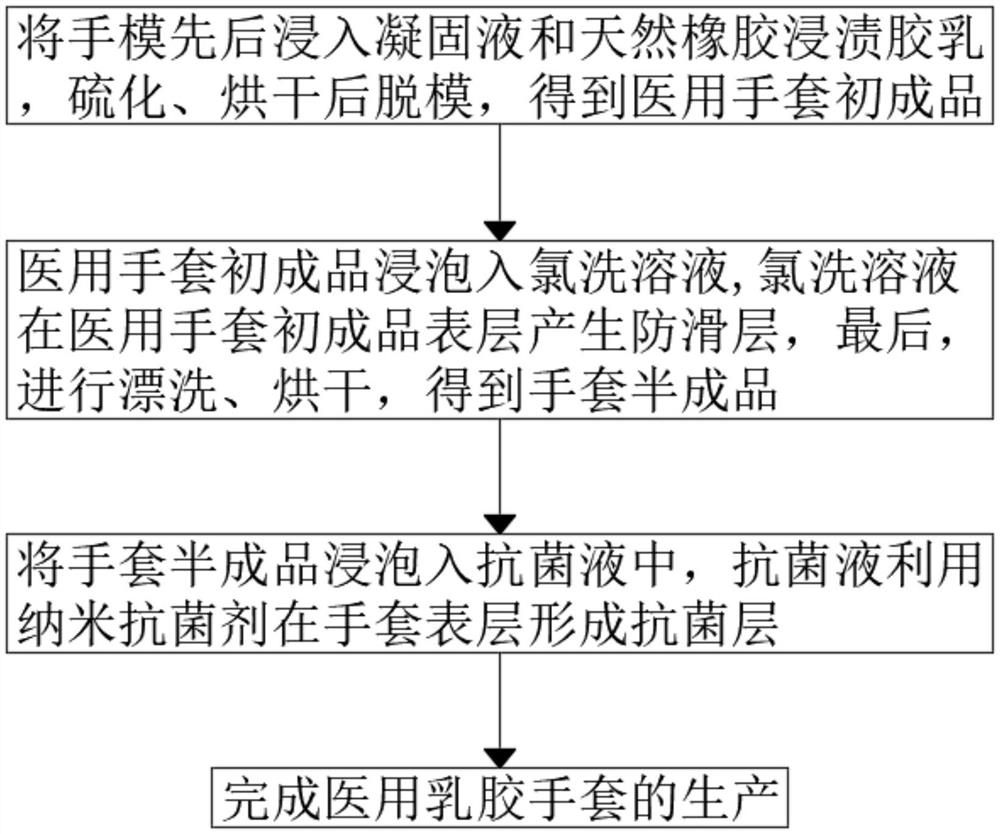

[0021] refer to figure 1 , embodiment one

[0022] A kind of medical latex glove production technique is proposed in the present embodiment, comprises the following steps:

[0023] Step 1: Dip molding: prepare natural rubber impregnated latex and coagulation liquid, natural rubber impregnated latex contains natural rubber emulsion, hydroxyethyl acrylate, sodium lauryl sulfate, potassium hydroxide, sulfur, zinc oxide, titanium dioxide and accelerator agent, select a suitable hand mold, heat the hand mold and immerse it in the coagulation liquid, let the surface of the hand mold fully contact with the coagulation liquid, take out the hand mold after immersion for 20-60 seconds, then dry it, and cool it to 30 At ~50°C, dip the hand mold in natural rubber-impregnated latex and stay in the natural rubber-impregnated latex for 40-60 seconds. After taking the hand-mold out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com