Variable-thickness laying layer parameterization design method for continuous fiber reinforced composite part

A reinforced composite material and continuous fiber technology, which is applied in the field of continuous fiber reinforced composite material parts, can solve problems such as the inability to comprehensively consider interaction effects, reduced calculation efficiency, and increased optimization iteration time, so as to improve lightweight effects, reduce material costs, The effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

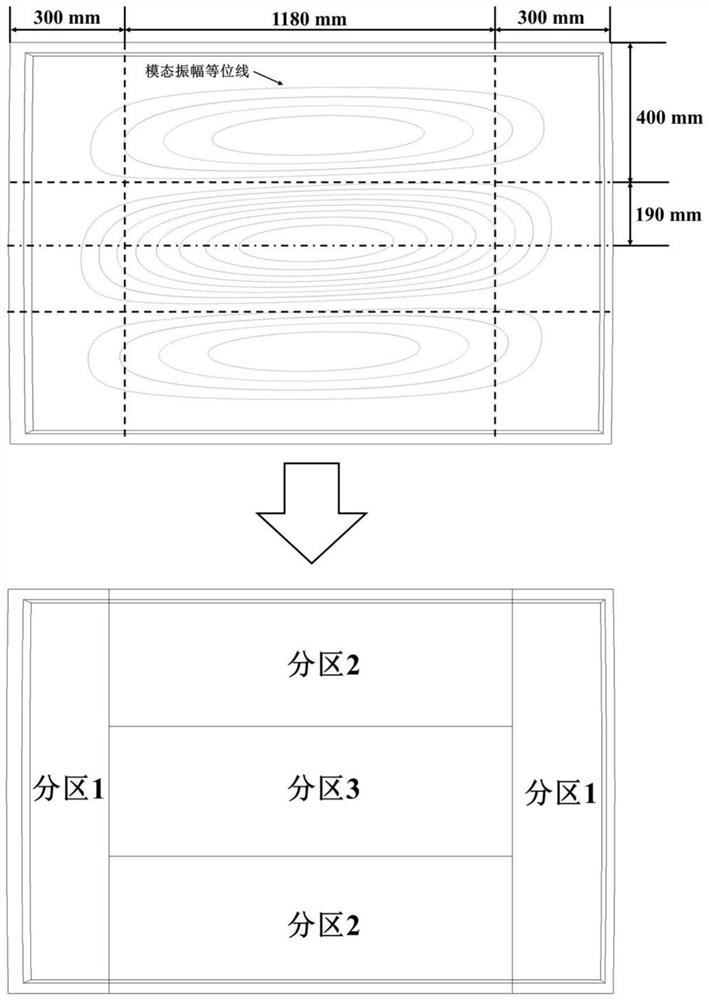

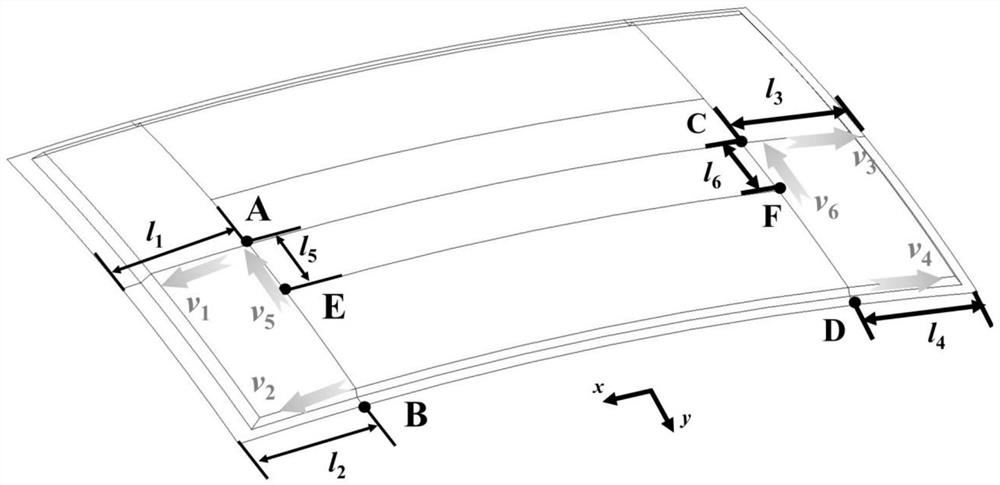

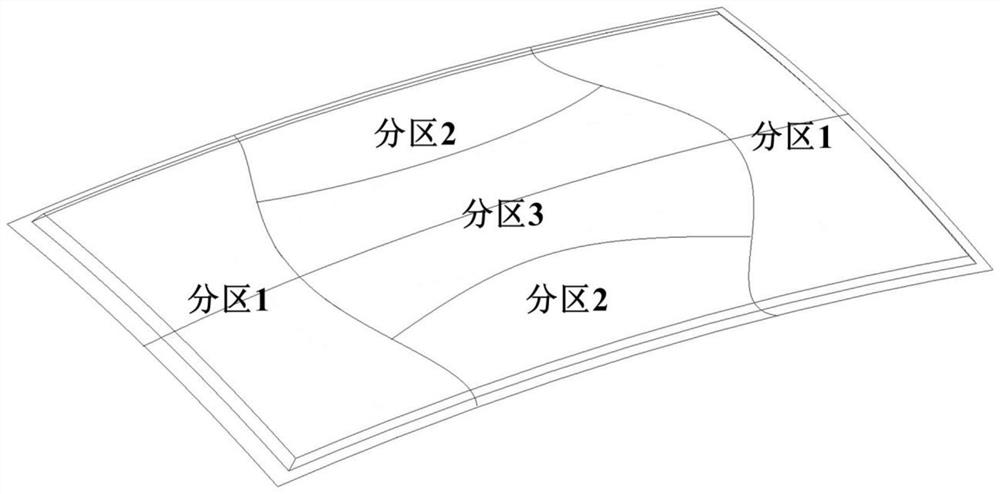

[0045] (1) Firstly, according to the load deformation characteristics and performance requirements of the roof panel, the number and position relationship of the variable-thickness laminate partitions of the parts are planned. The roof panel has a large area and low stiffness, and its main low-order constrained modal characteristics have an important impact on the vehicle interior vibration and noise (NVH) performance. Therefore, the design requirement of the roof panel is to constrain the roof panel weight by changing The thickness ply design maximizes the stiffness of the roof panel and minimizes the amplitude of the first-order constrained mode. Therefore, in this implementation case, the low-order constrained modal analysis of the roof panel should be carried out first. According to the connection constraint state of the roof panel with the side wall and the front and rear windshields in the working condition, the first-order elastic mode is calculated by constraining the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com