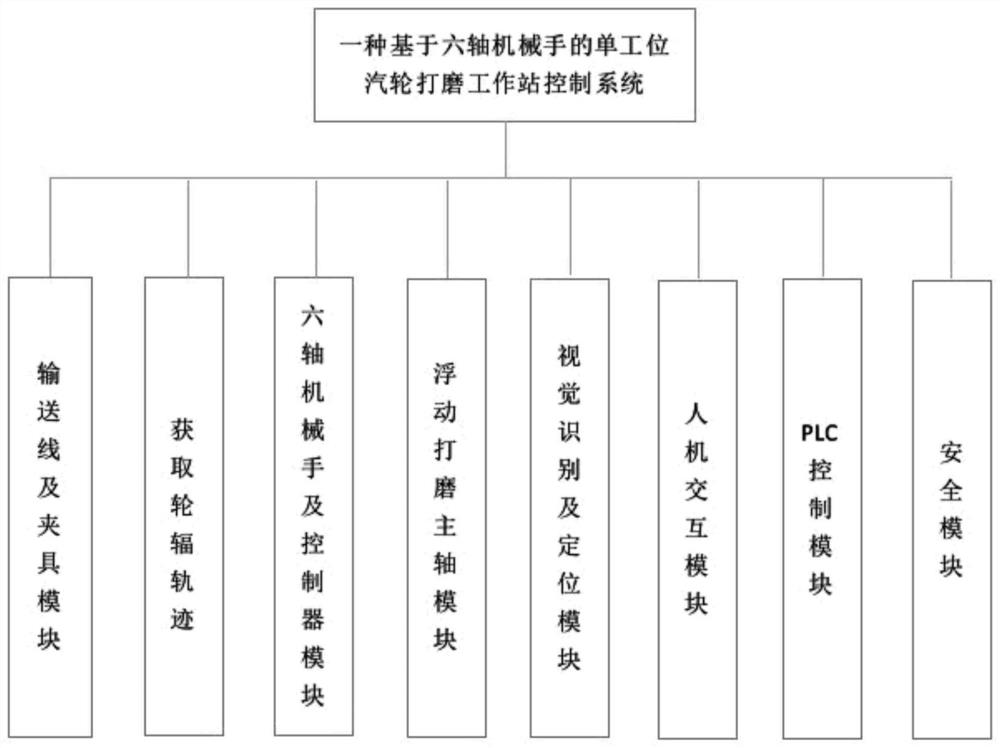

Turbine grinding workstation control system based on industrial robot

A technology of industrial robots and control systems, which is applied to automatic grinding control devices, machine tools suitable for grinding workpiece edges, and parts of grinding machine tools, etc. Dust harms workers' bodies and other issues to achieve the effect of reducing production labor costs, avoiding injuries, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

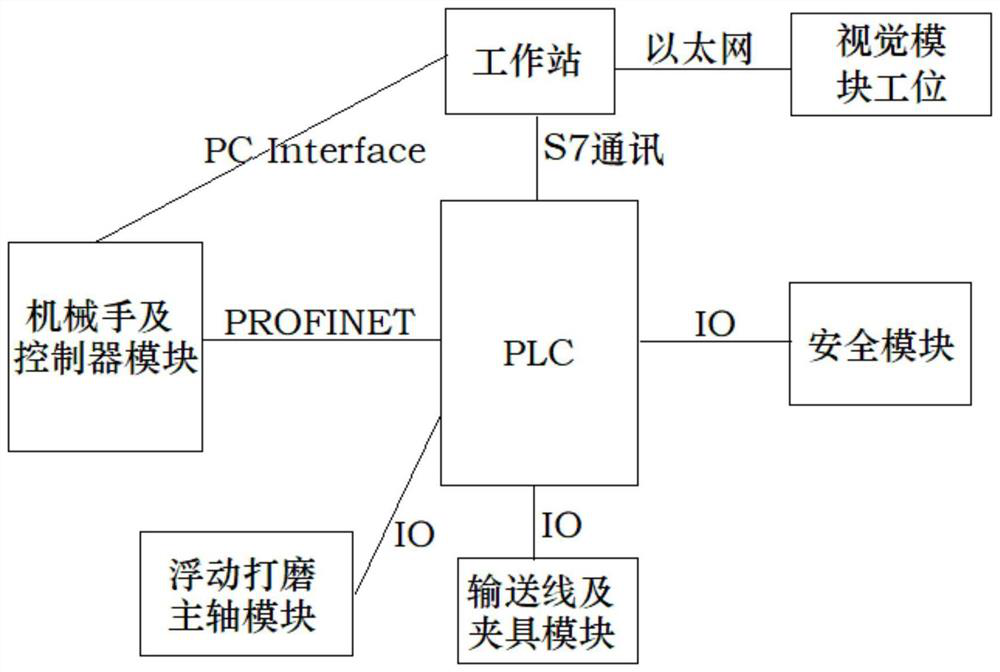

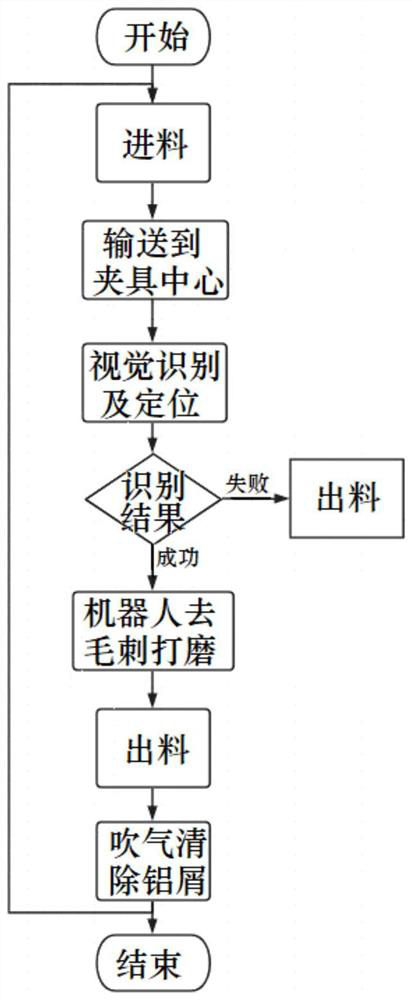

[0029] Referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention include the shape, structure, mutual position and connection relationship of each part, the function and working principle of each part, and the manufacturing process of the various components involved. And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0030] The control system of the steam turbine grinding workstation based on industrial robots has a workstation, which is a sealed shell, which can not only protect the internal equipment, but also prevent the workers from being injured, such as Figure 4 As shown, the shell constitutes the main body of the safety module. The side of the shell is equipped with a safety door and material inlet and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com