Monometallic positioning grillwork for reducing fuel rod position damage and pressure loss

A spacer, single-metal technology, applied in the assembly of fuel elements, reactor fuel elements, reduction of greenhouse gases, etc., can solve the problems of high spring stiffness, unfavorable rod surface protection, short spring compression stroke, etc., to reduce absorption, The effect of improving neutron economy and reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

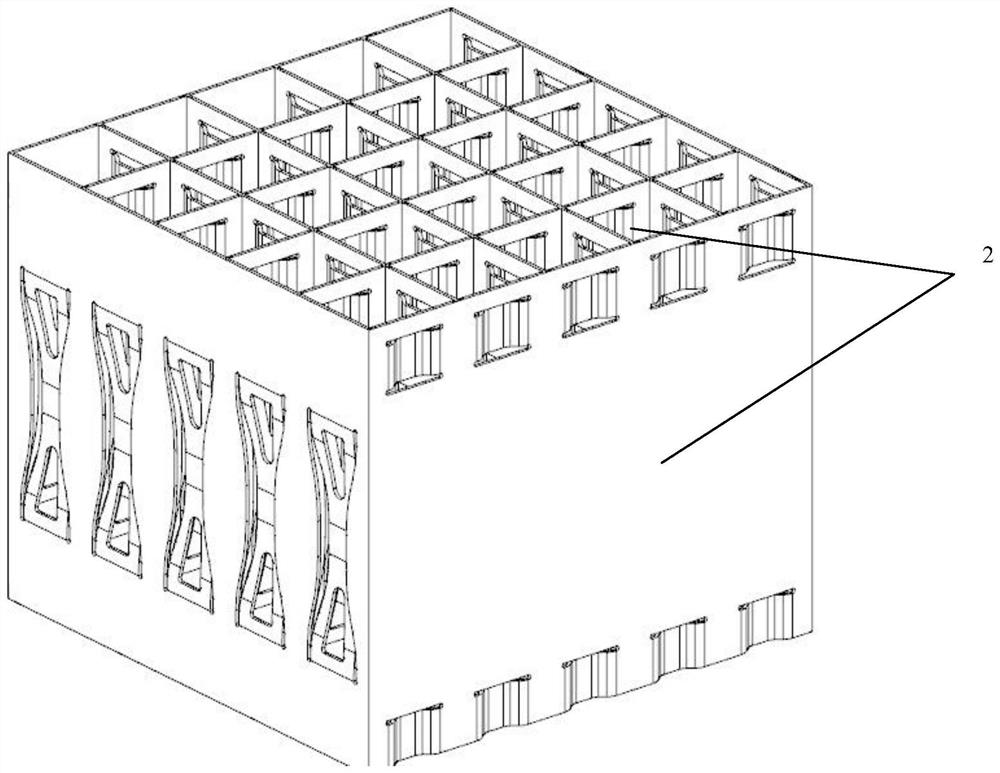

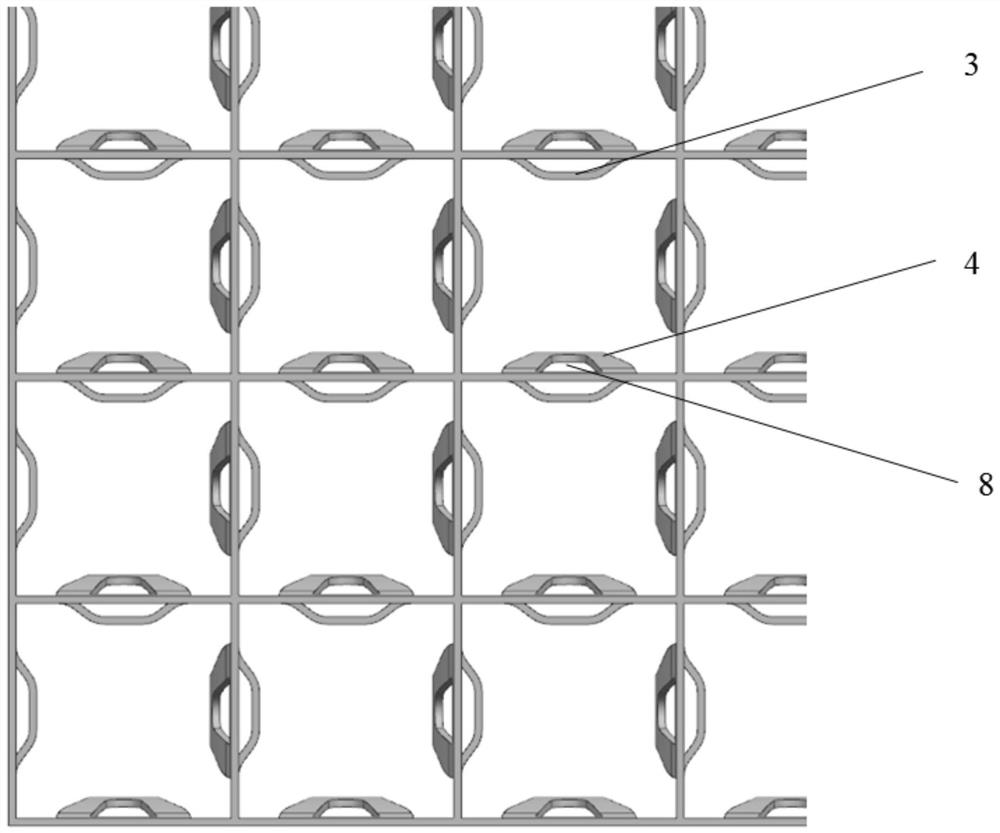

[0040] This embodiment proposes a single metal positioning grid that reduces fuel rod damage and pressure loss. The grid cell is composed of mutually perpendicular rigid protrusions and springs to form a clamping structure to provide clamping force for fuel rods. In the embodiment, by arranging springs along the axial direction of the fuel rods, and the springs are directly punched and formed from the wall surface of the strip, the entire grid is made of a single metal material, which is beneficial to neutron economy. The spring is guided by a continuous arc structure to reduce scratches on the cladding surface in the pull rod, and the streamlined structure is conducive to reducing the flow resistance of the coolant.

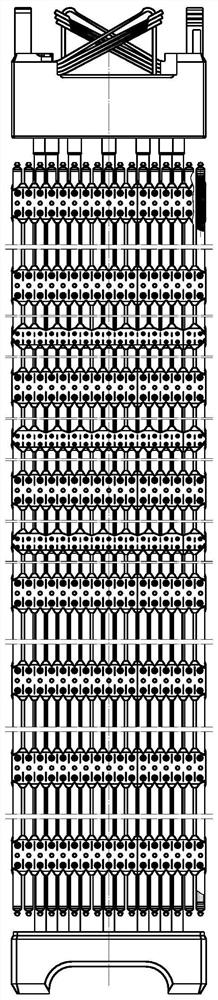

[0041] Specific as Figure 1-3 As shown, the positioning grid 1 of this embodiment is a square cell structure, and several strips 2 (the strips located inside the grid are inner strips, and the conditions outside the grid are outer strips) are mated with each ot...

Embodiment 2

[0048] The only difference between this embodiment and Embodiment 1 is that the side profile of the spring 4 of this embodiment is set as a reverse arc, that is, as Figure 5 As shown, the width of the two end regions 7 of the spring 4 in this embodiment is smaller than the width of the middle contact region 6 of the spring 4 .

Embodiment 3

[0050] The only difference between this embodiment and Embodiment 1 is that the side profile of the spring 4 of this embodiment is set to a straight edge, specifically as Figure 6 As shown, the width of the two end regions 7 of the spring 4 in this embodiment is equal to the width of the middle contact region 6 of the spring 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com