Wind power tower maintenance robot

A technology for wind power towers and robots, applied in the field of robots, can solve the problems that the gears and racks cannot be continuously meshed, and the robots are sent to the top of the wind power tower, etc., so as to achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is attached Figure 1-10 The application is described in further detail.

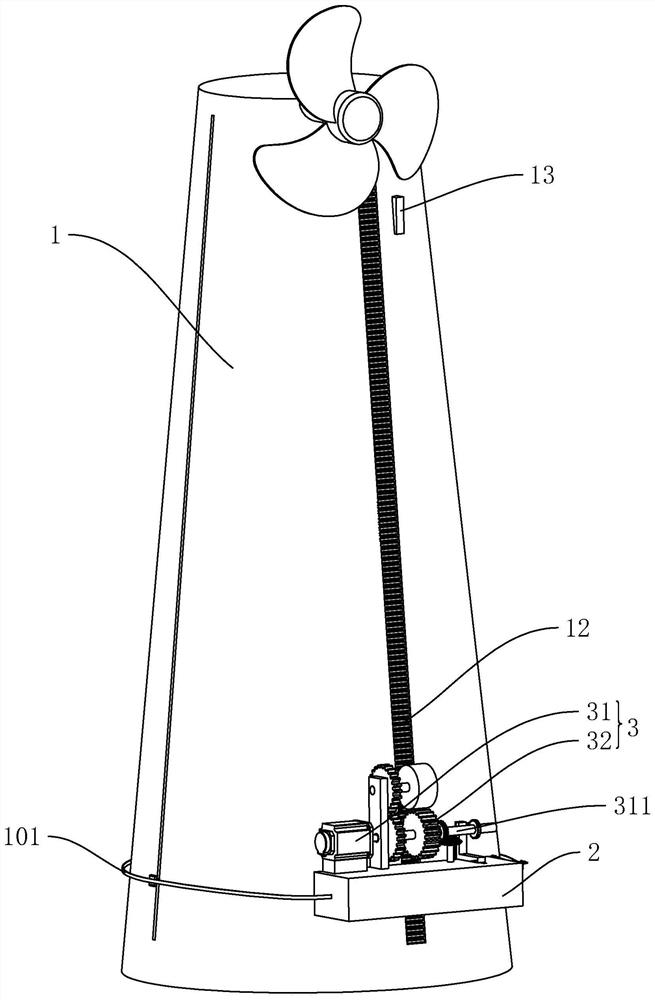

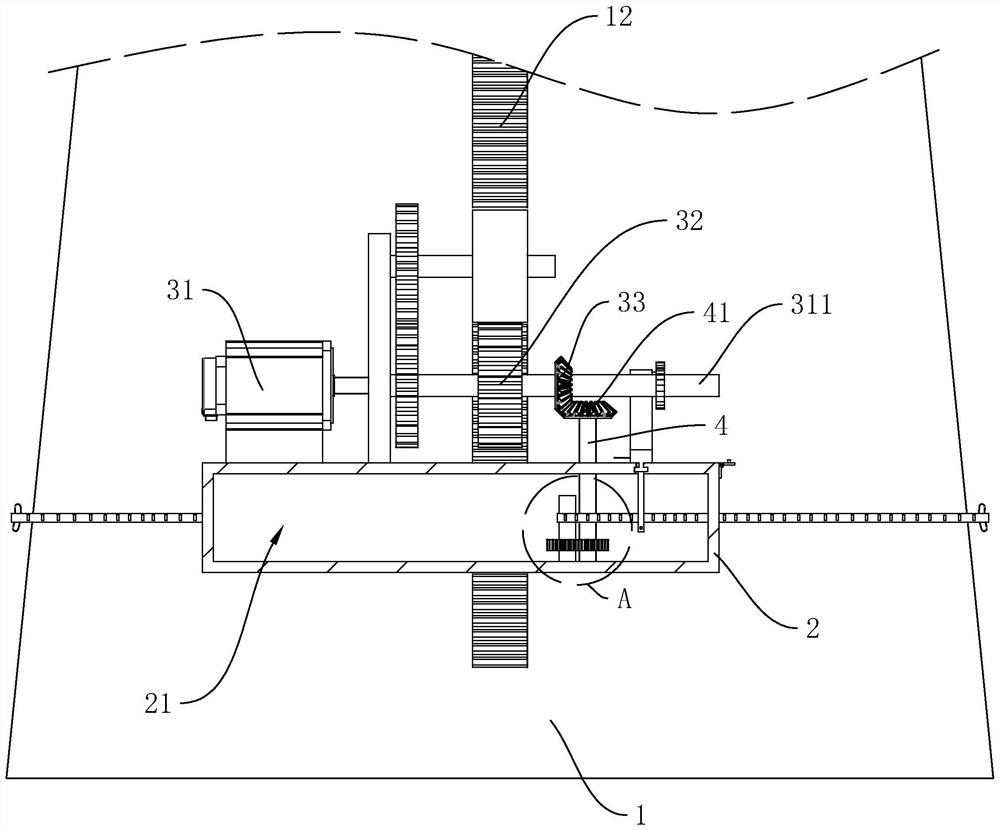

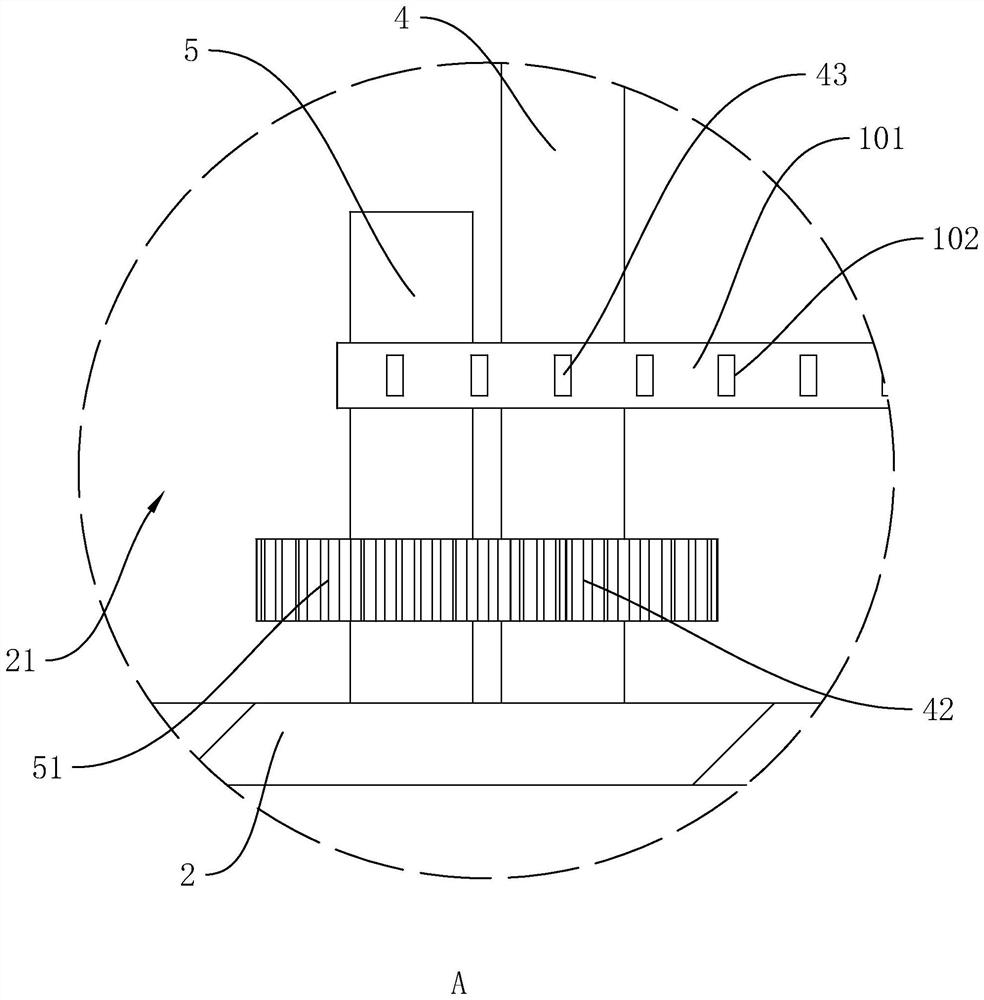

[0050] The embodiment of the present application discloses a wind power tower maintenance robot. refer to figure 1 A wind power tower maintenance robot includes a support plate 2, a shrink belt 101, a drive assembly 3 and a rack 12 arranged on a wind power tower 1. The rack 12 is welded and fixed from the bottom to the top of the wind power tower 1. The support plate 2 is located on the The side of the bar 12 away from the wind power tower 1 . The driving assembly 3 includes a motor 31 and a driving gear 32, the motor 31 is fixed on the top of the support plate 2 by bolts, the driving gear 32 is coaxially fixed with the rotating shaft 311 of the motor 31, the driving gear 32 is meshed with the rack 12, and the shrinkage belt 101 is wound around It is arranged on the wind power tower 1 and the support plate 2 so as to fix the support plate 2 on the side of the wind power tower 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com