Speed regulating method, speed regulating circuit and lifting device of permanent-magnet motor

A technology of permanent magnet motor and speed regulation method, which is applied in fields such as excitation or armature current control, lifts, transportation and packaging, etc. It can solve problems such as personnel insecurity, large power consumption, and waste of energy, and achieves simple control methods, Save electric energy and achieve the effect of speed control and decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

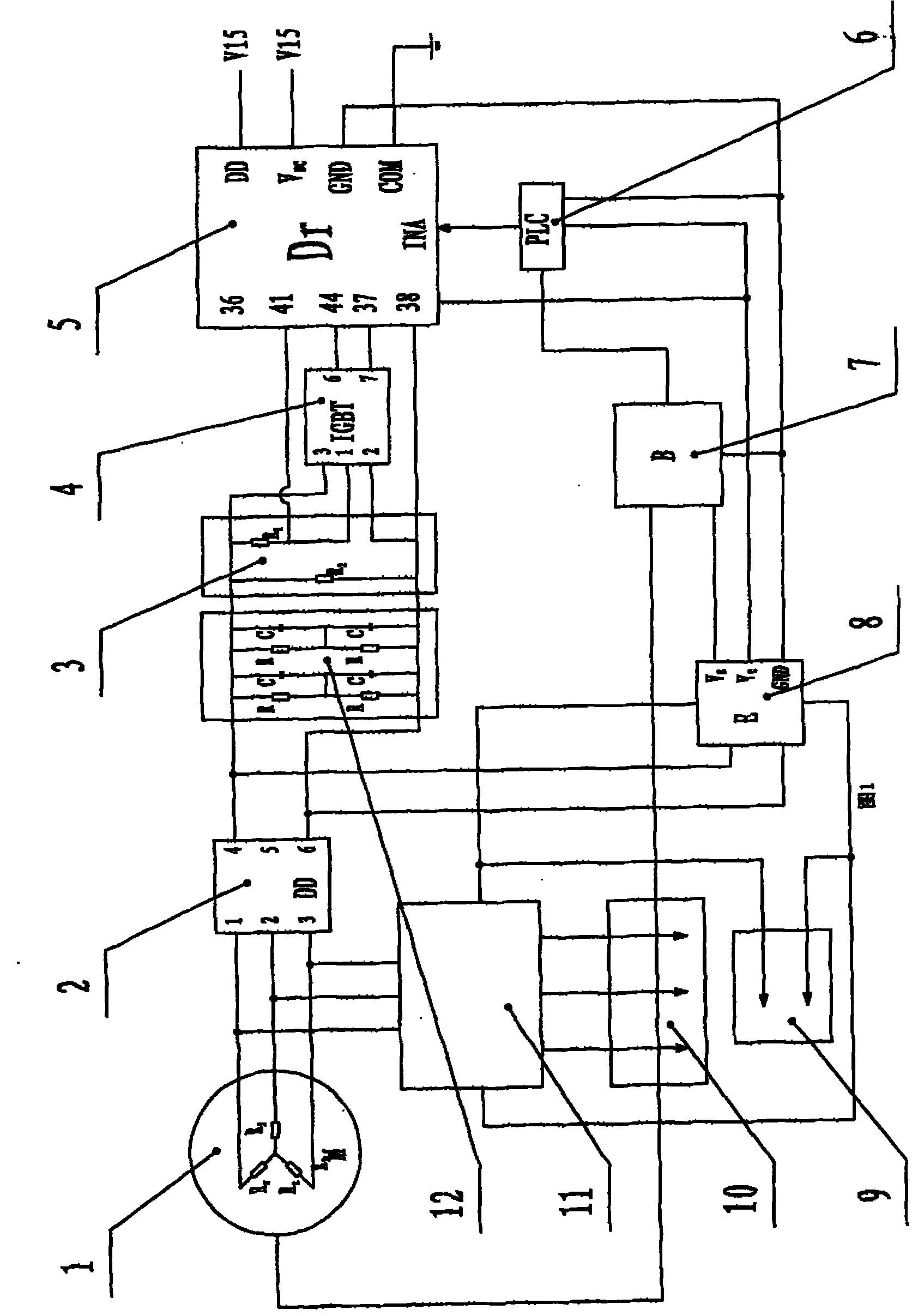

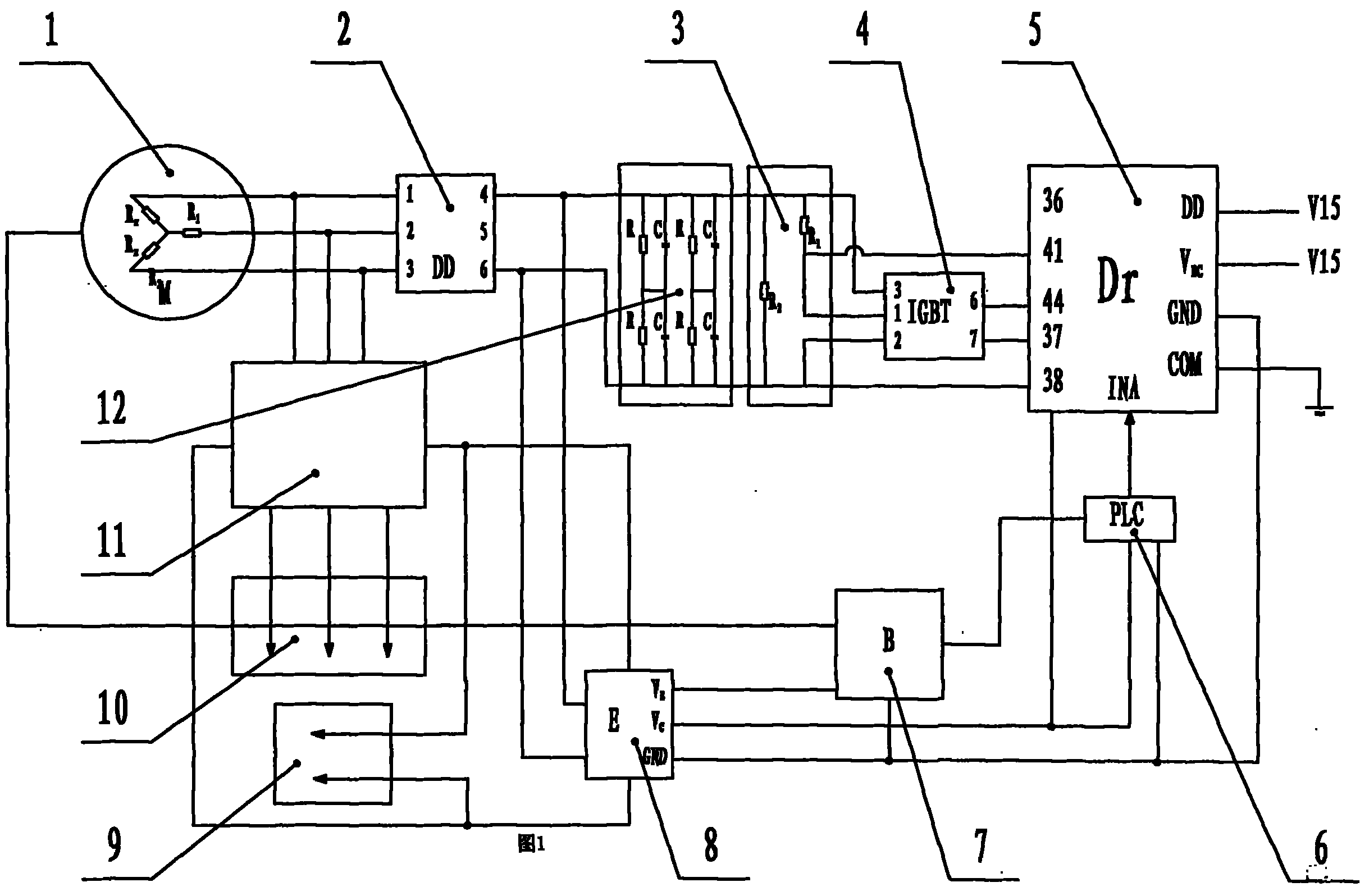

[0034] Such as figure 1 As shown, a speed regulation circuit of a permanent magnet motor, the permanent magnet motor is a permanent magnet motor 2, the speed regulation circuit includes: a winding circuit, the winding circuit includes a permanent magnet motor winding 1, a rectifier bridge 2, a filter circuit 3, a first function Consumption resistor R1, second power consumption resistor R2, insulated gate bipolar transistor (IGBT) 4, driver 5, programmable controller 6, encoder 7, storage battery 8, first interface 9, second interface 10 and inverter 11. The first power dissipation resistor R1 is connected in series with the switch terminal (pin 1 and pin 2) of the IGBT 4 and then connected in parallel with the second power dissipation resistor R2 to form an equivalent adjustable resistance, which is composed of the permanent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com