Monitoring system and method for forming grouting pipeline

A monitoring system and grouting pipe technology, applied in ceramic molding machines, auxiliary molding equipment, supply devices, etc., can solve the problems of green body air bubbles, pipeline lack of grouting, grouting time deviation, etc., to reduce variation and overlap. the probability of, and the effect of reducing the generation of forming bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

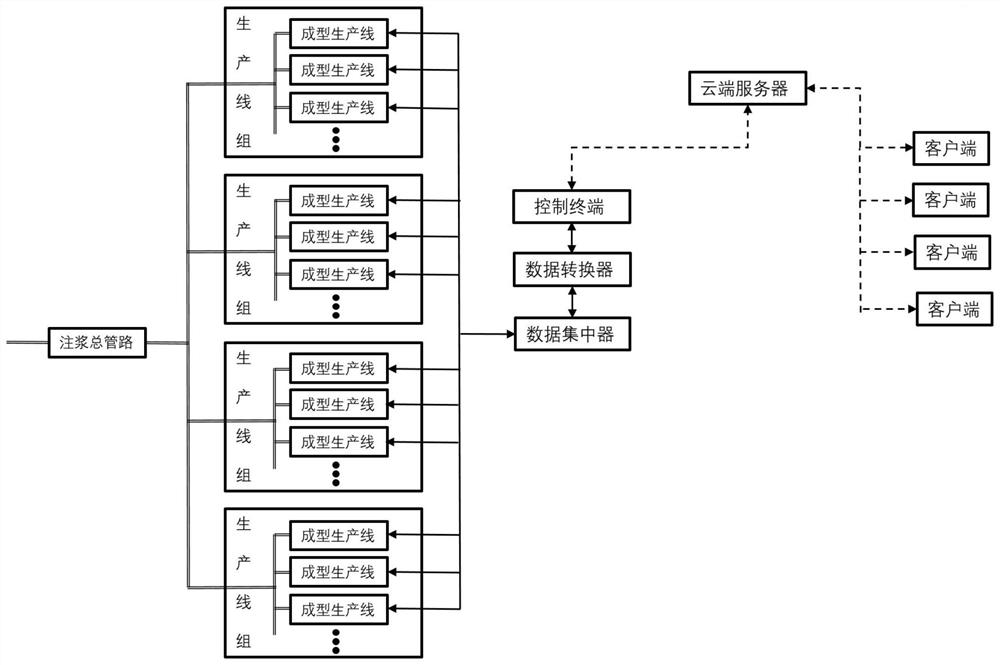

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

[0023] The invention provides a monitoring system for forming grouting pipelines, see figure 1 As shown, it includes multiple molding production lines and main grouting pipelines, and the molding production line is equipped with a control box.

[0024] The multiple molding production lines mentioned above are divided into multiple production line groups, the main grouting pipeline is connected to each production line group through a grouting sub-pipeline, and the grouting sub-pipelines pass through the molding production line in the production line group corresponding to the grouting branch pipeline connector . The monitoring system also includes:

[0025] The control terminal stores the shift schedules of multiple molding production lines. The shift schedule is based on the daily workload of the factory to plan the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com