Device and method for sequentially dyeing, washing and air-drying pathological slides

An air-drying device and technology for glass slides, which is applied in the field of medical devices, can solve the problems of sequential staining and washing of pancreatic pathological slides, cumbersome manual operation process, and influence on test results, so as to shorten the air-drying time, shorten the staining time, and reduce the size of the pancreas. The effect of device volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

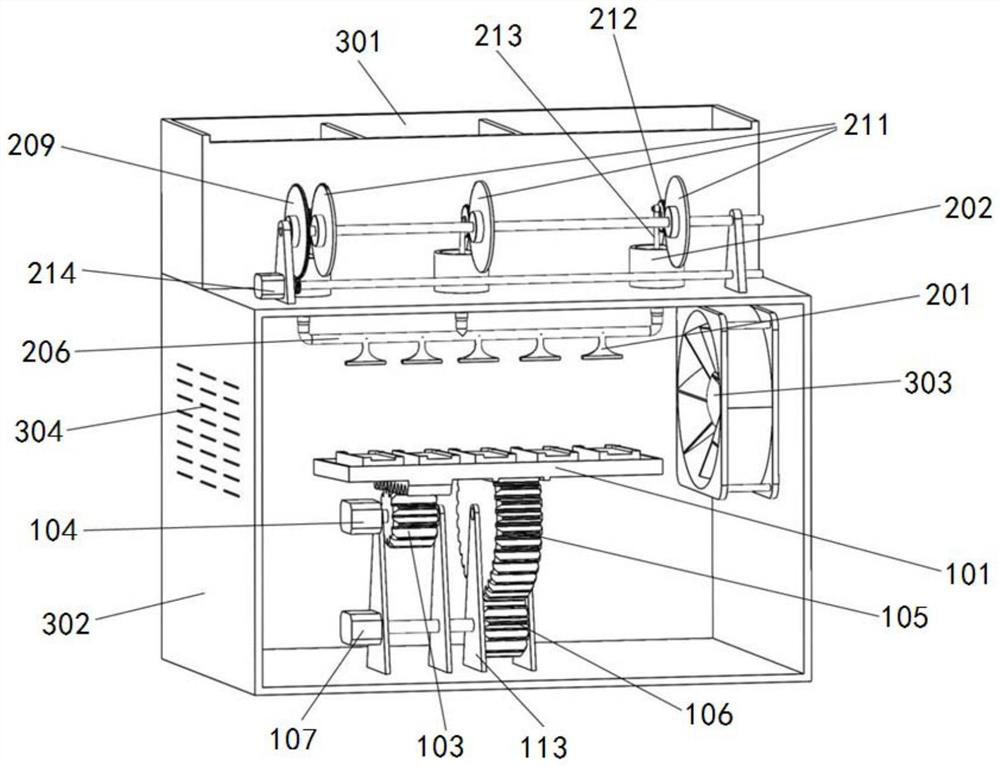

[0058] A device for sequential staining, washing, and air-drying of pathological slides, such as figure 1 As shown, it can be roughly divided into a moving mechanism 1, a pumping mechanism 2 and a casing 3.

[0059] Present embodiment kinematic mechanism 1 such as image 3 , Figure 4 As shown, a first motor 104 , a second motor 107 , a tilting pinion 106 , a tilting bull gear 105 and a translational gear 103 are installed on the moving mechanism frame 113 . Wherein, the tilt pinion 106 is connected with the second motor 107, and can rotate at a low speed under the control of the second motor 107; Turn at low speed. The large inclined gear 105 meshes with the small inclined gear 106, and the top surface of the large inclined gear 105 cooperates with the slide rail 108 on the lower end surface of the loading platform 101. At the same time, the rack 102 on the lower end surface of the loading platform 101 meshes with the translation gear 103 . Under the above-mentioned coop...

Embodiment 2

[0072] A sequential dyeing, washing, and air-drying device for pathological slides, comprising a movement mechanism 1, a pumping mechanism 2, and a box body 3. The motion mechanism is mainly composed of a loading table 101, a rack 102, a slide rail 108, a glass slide groove 109, a slope 110, a drain hole 111, a buckle 112, a first motor 104, a second motor 107, a motion mechanism frame 113, and a translation The gear 103, the inclined pinion gear 106, and the inclined large gear 105 constitute. The upper surface of the loading platform 101 is provided with a slide groove 109 , a slope 110 and a liquid drainage hole 111 . Both sides of the slide slot 109 are provided with buckles 112 for preventing the slide from moving. A rack 102 is provided on the lower surface of the loading platform 101, and is matched with a large inclined gear 105 through a groove (sliding rail 108). The rack 102 is meshed with the translation gear 103 , and the large inclined gear 105 is meshed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com