Cloth clamping tabouret

An embroidery frame and cloth clamping technology, which is applied in the field of embroidery machines, achieves the effects of good structural stability, labor-saving disassembly and assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

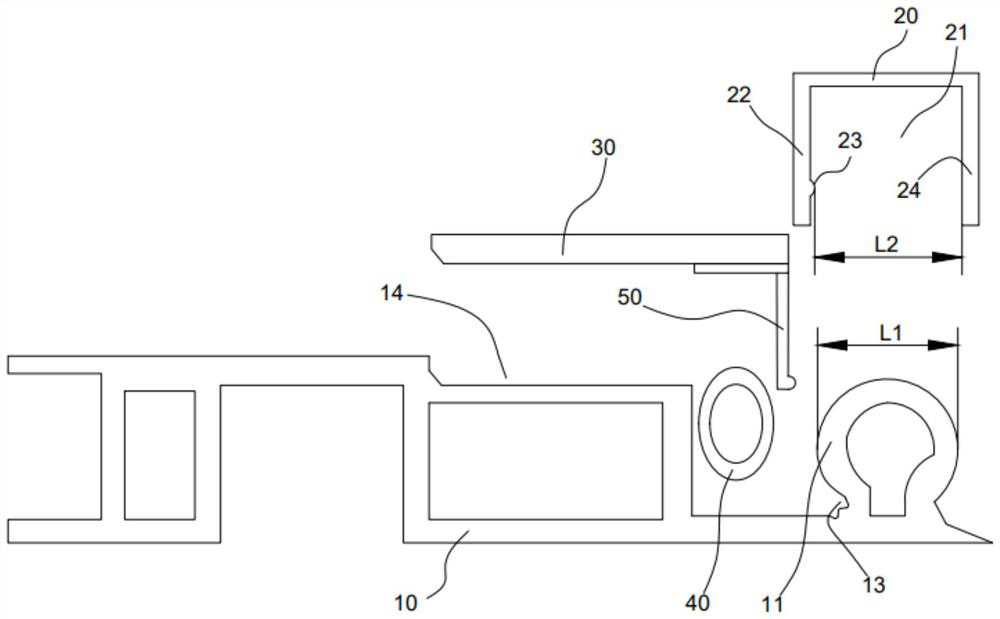

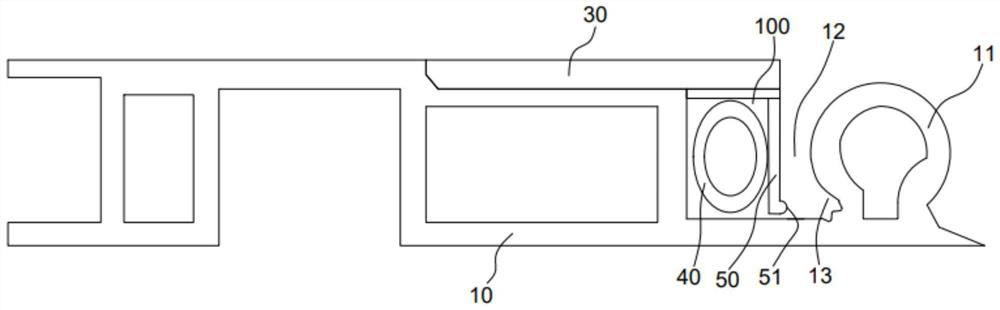

[0043] A cloth embroidery frame of this embodiment consists of Figure 1-3 The frame unit 10 shown constitutes. In this embodiment, one side of the frame unit 10 is provided with a fabric support unit 11, and the fabric support unit 11 is located inside the cloth clamping embroidery frame.

[0044] In this embodiment, the frame unit 10 is provided with a driving chamber 100 , the side of the driving chamber 100 facing the fabric supporting unit 11 is a movable wall 50 , and an active zone 12 is formed between the movable wall 50 and the fabric supporting unit 11 .

[0045] As a preference, in this embodiment, the top of the frame unit 10 is provided with an installation groove 14, and the cover plate 30 is fixedly installed in the installation groove 14, and the movable wall 50 is installed on the lower end of the cover plate 30 facing the fabric support unit 11. Part of the plate 30 forms the top wall of the drive chamber.

[0046] In this embodiment, the movable mode of th...

Embodiment 2

[0055] The cloth embroidery frame of this embodiment differs from Embodiment 1 in that, as Image 6 As shown, the drive system includes an eccentric rod 43 disposed in the drive cavity and a rotary drive mechanism (not shown in the figure, usually a motor) for driving the eccentric rod 43 to rotate. In this embodiment, the movement of the movable wall relative to the direction of the cloth supporting unit is realized through the rotational movement of the eccentric rod 43 .

Embodiment 3

[0057] The cloth embroidery frame of this embodiment differs from Embodiment 1 in that, as Figure 7 As shown, the lower end of the movable wall 50 is connected to the bottom of the drive chamber, and the upper end of the movable wall is a free-moving end.

[0058] Among them, in this embodiment, similar to Embodiment 1, the movable mode of the movable wall 50 is a feasible implementation mode that its lower end is hinged with the frame unit; another feasible mode is that the lower end of the movable wall 50 is hinged with the frame unit The units are fixedly connected, but the movable wall itself is made of elastic material with a certain degree of elasticity, such as spring steel, which can be reset after deformation.

[0059] It should be noted that, the driving system of this embodiment can be either the driving system of the first embodiment or the driving system of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com