Self-propelled device for building construction

A technology for building construction, traction devices, used in transportation and packaging, conveyors, mechanical conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

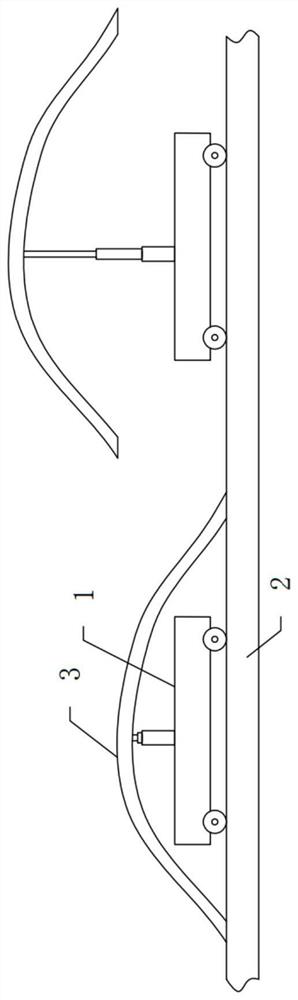

[0035] Such as figure 1 As shown, a self-propelled device for building construction includes a first track 2 and a car body 1, the bottom end of the car body 1 is rollingly connected with the upper end of the first track 2, the number of the car body 1 is more than one, and the upper end of the car body 1 is provided with The second track 3, the first track 2 and the second track 3 are arranged in parallel, the two ends of the second track 3 are respectively lapped on the first track 2, and the two ends of the second track 3 are respectively connected to the upper end of the first track 2 adaptation.

[0036] Specifically, the car body 1 is an electric rail car, the bottom end of the car body 1 is similar to the upper end of the first track 2 and is rollingly connected with the upper end of the first track 2, the first track 2 is a straight track, and the number of the car body 1 is two , the upper end of the car body 1 is equipped with a screw lifter, the lifting end of the ...

Embodiment 2

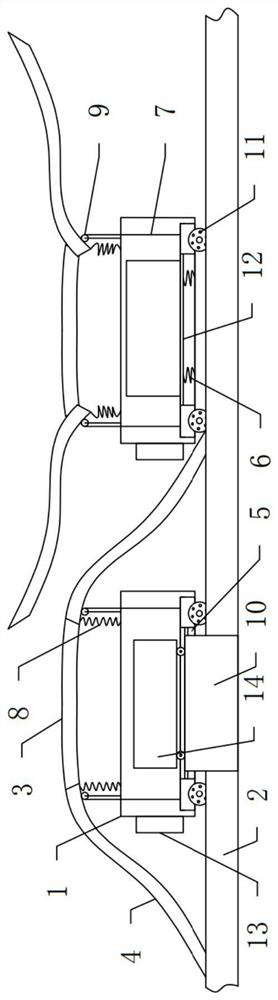

[0038] Such as figure 2 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, and this embodiment is further optimized on the basis of Embodiment 1: the two ends of the second track 3 are respectively slidably connected with connecting tracks 4, and the connecting tracks 4 are far away from the second track 3 One end of the first rail 2 upper surface fits.

[0039] Specifically, in order to facilitate the interaction between the two car bodies 1, the two ends of the second track 3 are slidably connected to the connecting track 4, and the end of the connecting track 4 away from the second track 3 is adapted to the upper surface of the first track 2. The connecting track 4 is slid and stretched at both ends of the second track 3. When in use, the staff only need to slide the connecting track 4 into or out of the second track 3 to facilitate cross driving. The setting of the sliding connection can facilitate the second Track 3 is retracted to s...

Embodiment 3

[0045] Such as image 3 , Figure 4 with Figure 5 As shown, the structure of this embodiment is roughly the same as that of Embodiment 2, and this embodiment is further optimized on the basis of Embodiment 2: the first rail 2 and the second rail 3 are both inverted trapezoids with upper ends open.

[0046] Specifically, both the first rail 2 and the second rail 3 are inverted trapezoids with an open upper end, and the driving wheels at the bottom of the car body 1 can be restricted by setting the inverted trapezoid to prevent the car body 1 from leaving the first rail 2 during the movement process. Or the second track 3, the first track 2 and the second track 3 are set in an inverted trapezoid, and at the same time, the two ends of the connecting track 4 can be connected with the first track 2 and the second track 3 respectively, and the setting of the inverted trapezoid can be It is suitable for ordinary vehicles to increase practicality.

[0047] As a further optimizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com